Stable and clean peelable glue-coated medical device packaging material and preparation method

A technology for medical devices and packaging, which is applied in the field of materials and preparations for rubberized medical device packaging, can solve the unsolved problems of stable peeling and easy peeling of medical device packaging materials, and achieves improved material peeling feel, easy peeling, and improved thermal stability. The effect of bond fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

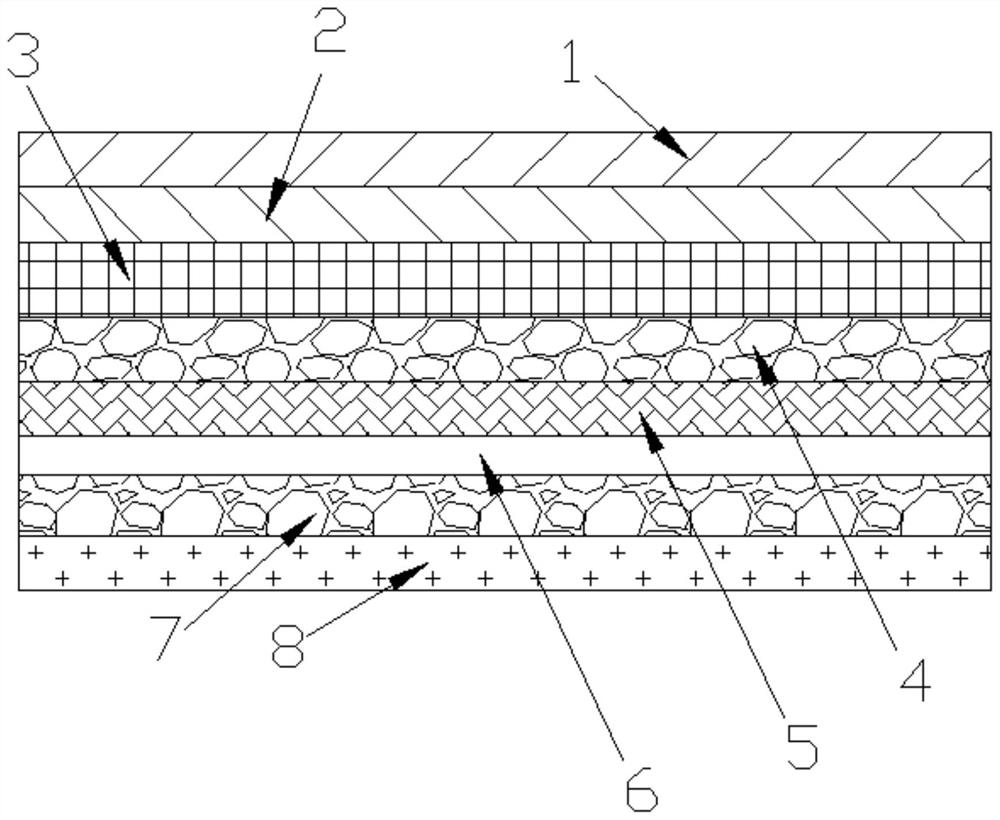

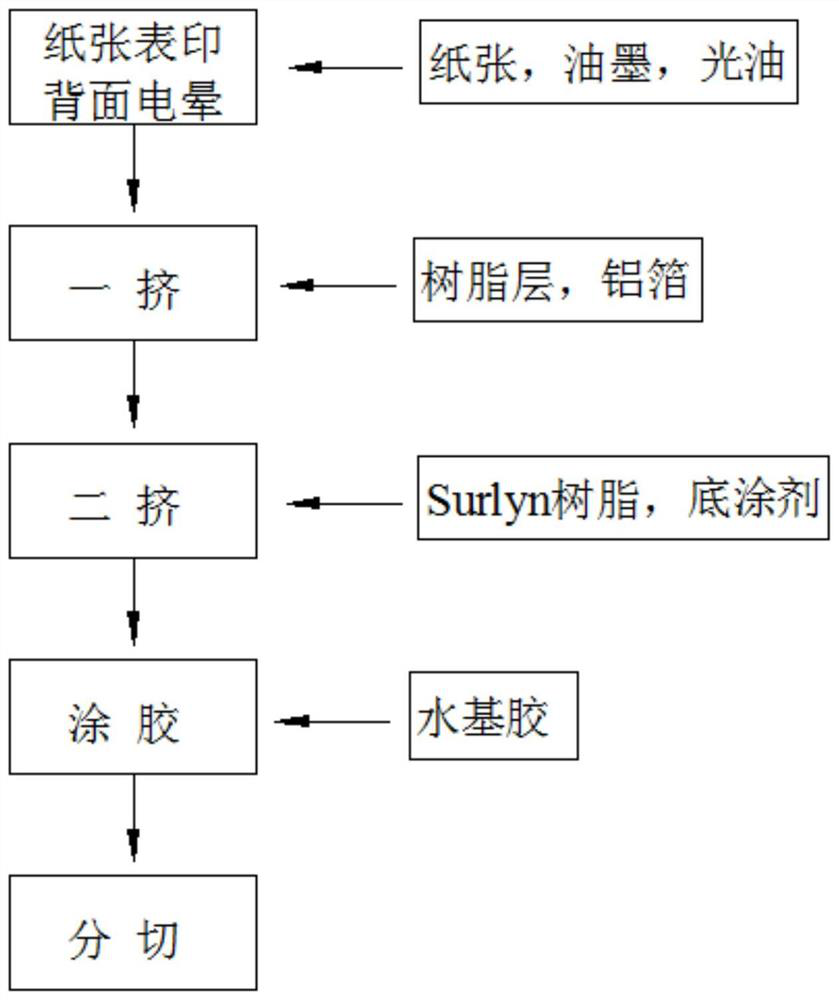

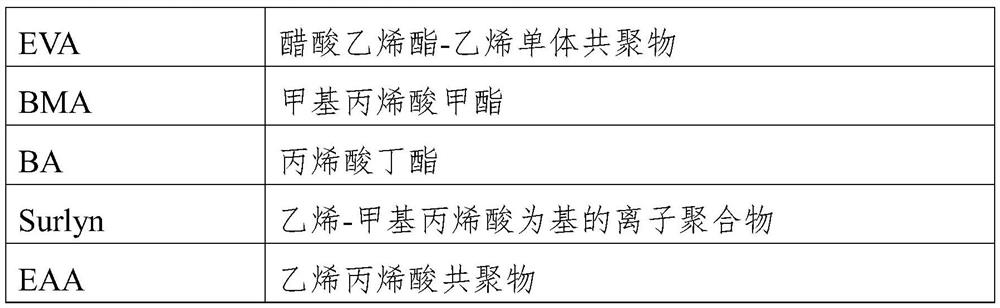

[0033] Such as figure 1 , figure 2 as shown ( figure 2 The right side of the middle is the raw materials that need to be added in each process), the present invention is a glue-coated medical device packaging material that can be peeled off stably and cleanly, including a varnish protective layer 1 and a paper layer 3 printed with ink 2 arranged from top to bottom , the barrier layer 5 and the glue layer 8; the two sides of the barrier layer 5 are respectively extruded with a resin layer, and the main resin of the glue layer 8 is a water-based adhesive. The glue layer 8 includes main resin, deionized water, film-forming aid, tackifying resin, leveling agent and defoamer, and the weight percentages of each component are 65%, 15%, 6%, 4%, 4%, respectively. 6%; The main body resin is that the weight percentages of EVA, methyl methacrylate, and n-butyl acrylate in the main body emulsion are respectively 58%, 26%, and 16% of the main body emulsion, and its viscosity is 300mPa.s...

Embodiment 2

[0038] Such as figure 1 , figure 2 as shown ( figure 2 The right side of the middle is the raw materials that need to be added in each process), the present invention is a glue-coated medical device packaging material that can be peeled off stably and cleanly, including a varnish protective layer 1 and a paper layer 3 printed with ink 2 arranged from top to bottom , the barrier layer 5 and the glue layer 8; the two sides of the barrier layer 5 are respectively extruded with a resin layer, and the main resin of the glue layer 8 is a water-based adhesive. The glue layer 8 includes main resin, deionized water, film-forming aid, tackifying resin, leveling agent and defoamer, and the weight percentages of each component are 65%, 15%, 6%, 4%, 4%, respectively. 6%; The main body resin is that the weight percentages of EVA, methyl methacrylate, and n-butyl acrylate in the main body emulsion are respectively 58%, 26%, and 16% of the main body emulsion, and its viscosity is 300mPa.s...

Embodiment 3

[0044] Such as figure 1 , figure 2 as shown ( figure 2 The right side of the middle is the raw materials that need to be added in each process), the present invention is a glue-coated medical device packaging material that can be peeled off stably and cleanly, including a varnish protective layer 1 and a paper layer 3 printed with ink 2 arranged from top to bottom , the barrier layer 5 and the glue layer 8; the two sides of the barrier layer 5 are respectively extruded with a resin layer, and the main resin of the glue layer 8 is a water-based adhesive. The glue layer 8 includes main resin, deionized water, film-forming aid, tackifying resin, leveling agent and defoamer, and the weight percentages of each component are respectively 75%, 12%, 4%, 3%, 3%, 3%; The main body resin is that the weight percentages of EVA, methyl methacrylate, and n-butyl acrylate in the main body emulsion are respectively 58%, 26%, and 16% of the main body emulsion, and its viscosity is 300mPa.s,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com