Abrasion-resisting anti-slip strip

An anti-skid strip and wear-resistant technology, which is applied in the field of anti-skid materials, can solve the problems of non-wear resistance, non-guaranteed anti-skid performance, and short service life, and achieve good wear resistance, good anti-skid effect, and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

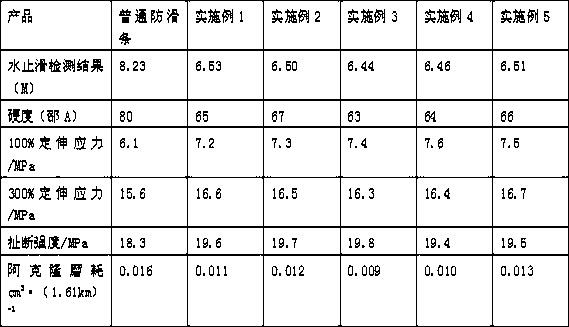

Examples

Embodiment 1

[0014] Weighing: 20 kg of perfluoroether rubber, 41 kg of nitrile silicone rubber, 15 kg of butyl rubber, 8 kg of zinc oxide, 10 kg of nano calcium carbonate, 0.5 kg of antioxidant, 11 kg of carbon fiber, 6 kg of magnesium oxide and 1.6 kg of vulcanizing agent kg to make the wear-resistant anti-skid strip of the present invention.

Embodiment 2

[0016] Weighing: 21 kg of perfluoroether rubber, 43 kg of nitrile silicone rubber, 16 kg of butyl rubber, 9 kg of zinc oxide, 11 kg of nano calcium carbonate, 0.7 kg of antioxidant, 12 kg of carbon fiber, 7 kg of magnesium oxide and 1.9 kg of vulcanizing agent kg to make the wear-resistant anti-skid strip of the present invention.

Embodiment 3

[0018] Weighing: 23 kg of perfluoroether rubber, 45 kg of nitrile silicone rubber, 19 kg of butyl rubber, 11 kg of zinc oxide, 12 kg of nano-calcium carbonate, 0.8 kg of antioxidant, 15 kg of carbon fiber, 8 parts of magnesium oxide and 2.2 parts of vulcanizing agent kg to make the wear-resistant anti-skid strip of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com