Point switch retention force tester

A holding force and tester technology, applied in force/torque/work measuring instruments, instruments, measuring devices, etc., can solve the technical problems that cannot be solved in the test, achieve good anti-slip effect, and facilitate the measurement of holding force and device. Overall stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

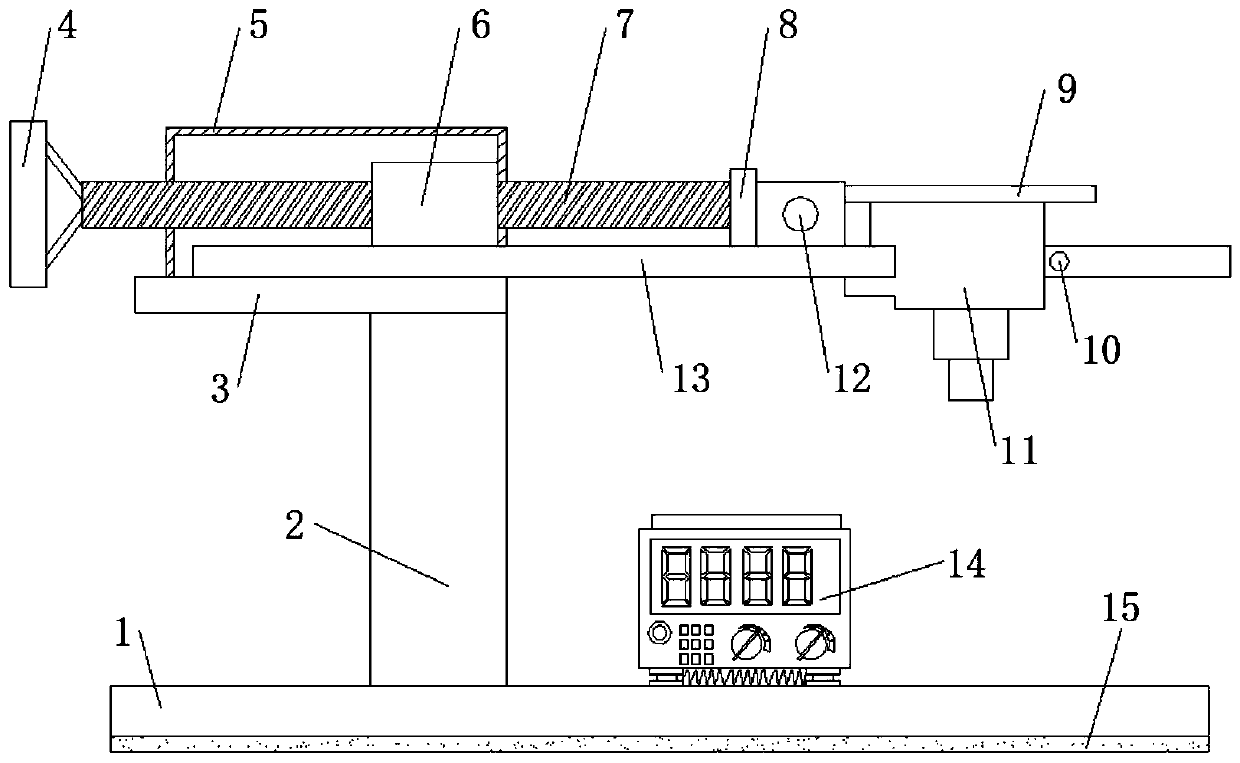

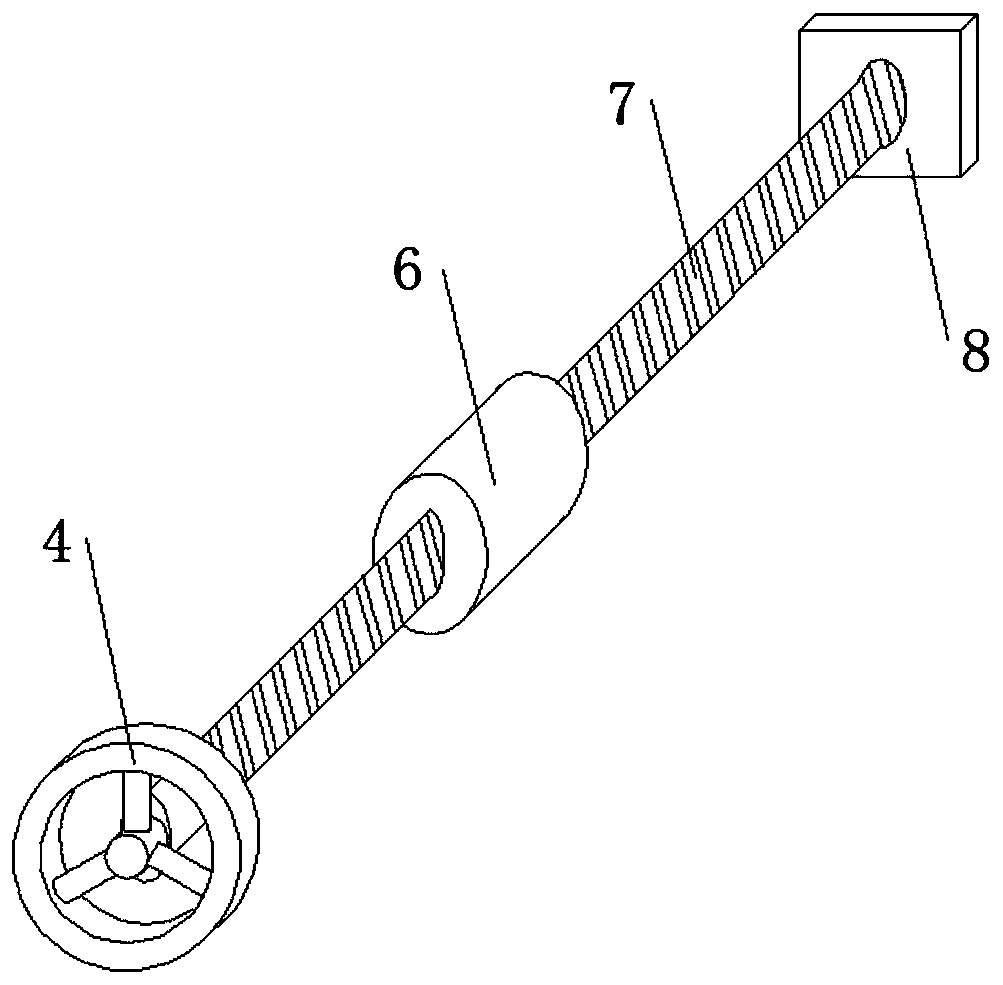

[0023] refer to Figure 1-2 , a switch machine holding force tester, comprising a base plate 1, a base 2 is fixed on the top outer wall of the base plate 1 by bolts, a support plate 3 is fixed on the top outer wall of the base 2 by bolts, and a support plate 3 is fixed on the top outer wall of the support plate 3 by bolts The nut guard 5 is fixed, the top outer wall of the support plate 3 is fixed with a main shaft 13 by bolts, and one end of the main shaft 13 is located inside the nut guard 5, and a pushing mechanism is provided on one side of the outer wall of the nut guard 5 A pressure sensor 12 is slidably clamped on one side of the outer wall of the main shaft 13, and a test piece 11 is slidably clamped at one end of the main shaft 13 close to the pressure sensor 12, and a digital display dynamometer 14 is fixed on the top outer wall of the bottom plate 1 by bolts. , the signal output end of the pressure sensor 12 is connected with the signal input end of the digital disp...

Embodiment 2

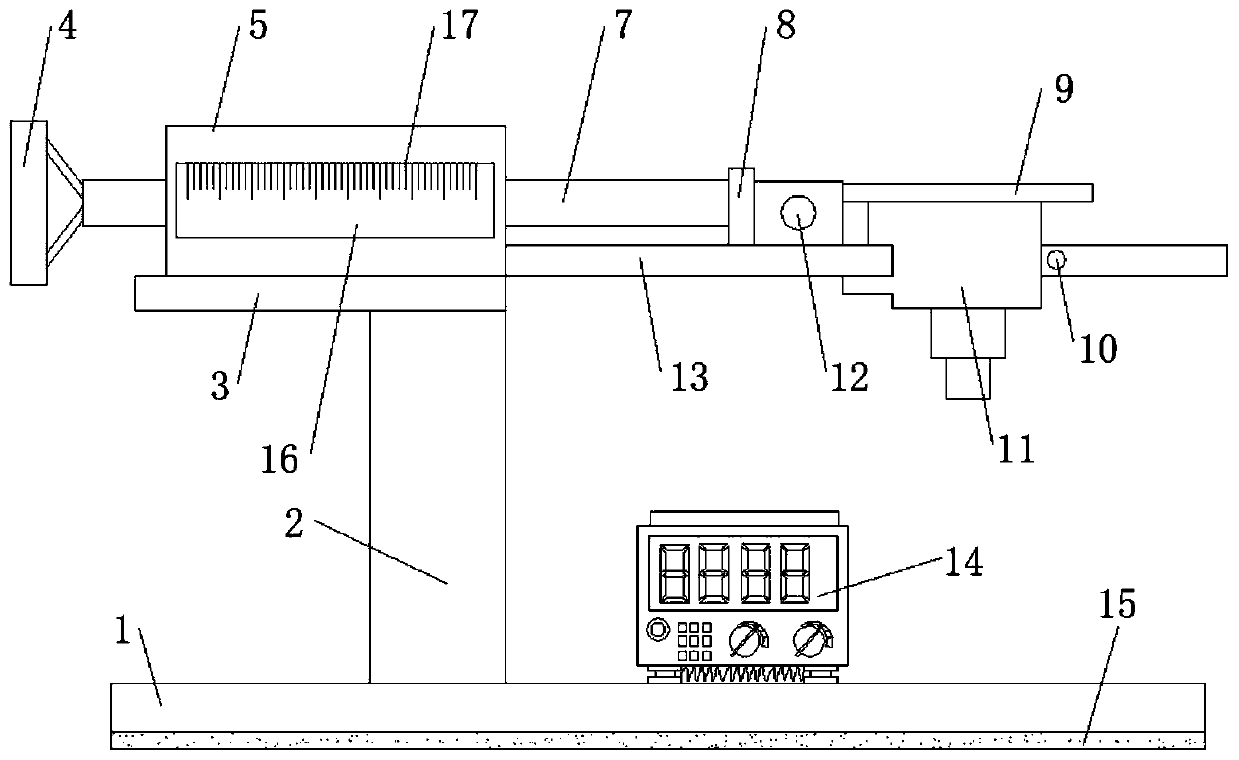

[0027] refer to image 3 , a switch machine holding force tester. Compared with Embodiment 1, this embodiment has an installation opening on one side of the mother guard plate 5, and an observation window 16 is clamped on the inner wall of the installation opening. The observation window Scale marks 17 are engraved on one side outer wall of 16.

[0028] During use, there is observation window 16 on the side outer wall of silk mother guard plate 5, and scale mark 17 is arranged, convenient staff watches how much distance hand wheel 4 shakes and advances.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com