Cryogenic rubber thermal insulation material and preparation method thereof

A thermal insulation, rubber technology, applied in sustainable manufacturing/processing, climate sustainability, chemical industry, etc., to achieve the effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

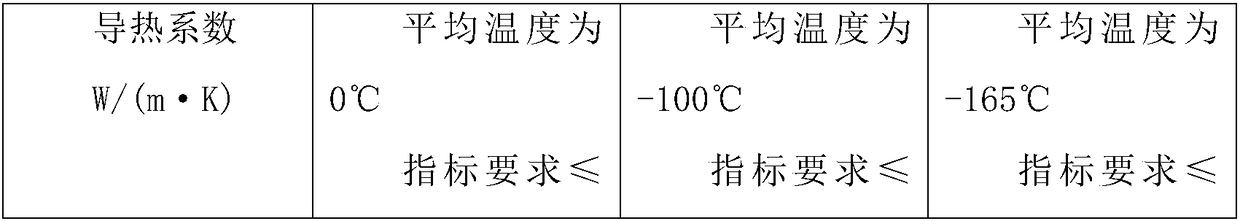

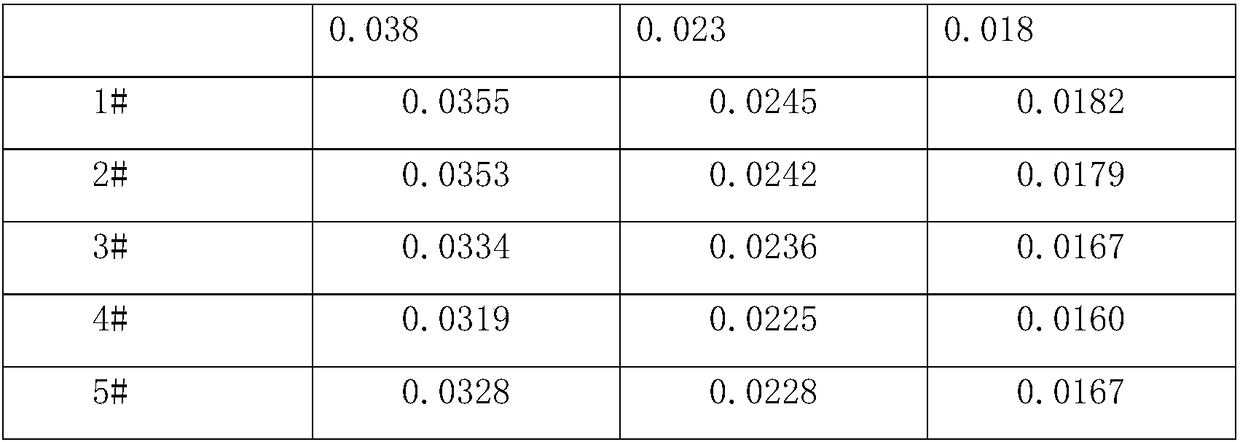

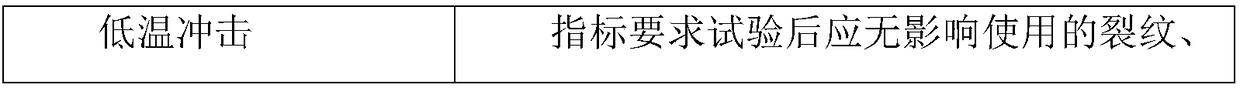

Examples

Embodiment 1

[0024] (1) According to EPDM 15kg, butyl rubber (IIR) 5kg, butadiene rubber (BR) 5kg, high temperature foaming agent (AC) 10kg, antimony trioxide (Sb2o3) 5kg, zinc oxide 0.5kg, dioctyl ester (DOP) 10kg, antioxidant (4020) 0.1kg, antioxidant (AST-500) 1.2kg, microsphere foaming agent (F-82) 1.5kg, protective wax (HGB-3) 1kg, polyethylene glycol (PEG) 1kg, stearic acid 0.1kg, aluminum hydroxide 15kg, antioxidant (RD) 0.3kg, anti-scorch agent (PVI) 0.2kg, sulfur 0.2kg, diethylenedithiocarbamic acid The weight of zinc (E) 0.2kg and zinc dibutyl dithiocarbamate (B) 0.3kg takes raw materials;

[0025] (2) High temperature rubber mixing: the weighed EPDM rubber (EPDM), butyl rubber (IIR), butadiene rubber (BR), high temperature foaming agent (AC), antimony trioxide (Sb2o3) , zinc oxide, dioctyl (DOP), antiaging agent (4020), antioxidant (AST-500), protective wax (HGB-3), polyethylene glycol (PEG), stearic acid, aluminum hydroxide, Anti-aging agent (RD) and anti-scorch agent (PVI) a...

Embodiment 2

[0033] (1) According to EPDM 18kg, butyl rubber (IIR) 6kg, butadiene rubber (BR) 6kg, high temperature foaming agent (AC) 11kg, antimony trioxide (Sb2o3) 5kg, zinc oxide 0.6kg, dioctyl ester (DOP) 11kg, antioxidant (4020) 0.1kg, antioxidant (AST-500) 1.4kg, microsphere foaming agent (F-82) 1.7kg, protective wax (HGB-3) 1.2kg, polyethylene glycol (PEG) 1.2kg, stearic acid 0.2kg, aluminum hydroxide 16kg, antioxidant (RD) 0.4kg, anti-scorch agent (PVI) 0.3kg, sulfur 0.3kg, diethylene disulfide The weight of zinc substituted carbamate (E) 0.2kg and dibutyl dithiocarbamate zinc (B) 0.4kg takes raw materials;

[0034] (2) High temperature rubber mixing: the weighed EPDM rubber (EPDM), butyl rubber (IIR), butadiene rubber (BR), high temperature foaming agent (AC), antimony trioxide (Sb2o3) , zinc oxide, dioctyl (DOP), antiaging agent (4020), antioxidant (AST-500), protective wax (HGB-3), polyethylene glycol (PEG), stearic acid, aluminum hydroxide, Anti-aging agent (RD) and anti-sco...

Embodiment 3

[0042] (1) According to EPDM 21kg, butyl rubber (IIR) 7kg, butadiene rubber (BR) 7kg, high temperature foaming agent (AC) 12kg, antimony trioxide (Sb2o3) 6kg, zinc oxide 0.7kg, dioctyl ester (DOP) 12kg, antioxidant (4020) 0.3kg, antioxidant (AST-500) 1.6kg, microsphere foaming agent (F-82) 1.9kg, protective wax (HGB-3) 1.8kg, polyethylene glycol (PEG) 1.5kg, stearic acid 0.2kg, aluminum hydroxide 17kg, antioxidant (RD) 0.4kg, anti-scorch agent (PVI) 0.3kg, sulfur 0.3kg, diethylene dithio The weight of zinc carbamate (E) 0.3kg and zinc dibutyldithiocarbamate (B) 0.3kg takes raw materials;

[0043] (2) High temperature rubber mixing: the weighed EPDM rubber (EPDM), butyl rubber (IIR), butadiene rubber (BR), high temperature foaming agent (AC), antimony trioxide (Sb2o3) , zinc oxide, dioctyl (DOP), antiaging agent (4020), antioxidant (AST-500), protective wax (HGB-3), polyethylene glycol (PEG), stearic acid, aluminum hydroxide, Anti-aging agent (RD) and anti-scorch agent (PVI) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com