Microelectrolysis based advanced oxidation water treatment system and method

A treatment system and treatment method technology, applied in the field of advanced oxidized water treatment system, can solve the problems of easy passivation of the surface, limited duration of iron-carbon micro-electrolysis, and insignificant effect of micro-electrolysis reaction, so as to reduce the addition amount and enhance the purification. effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

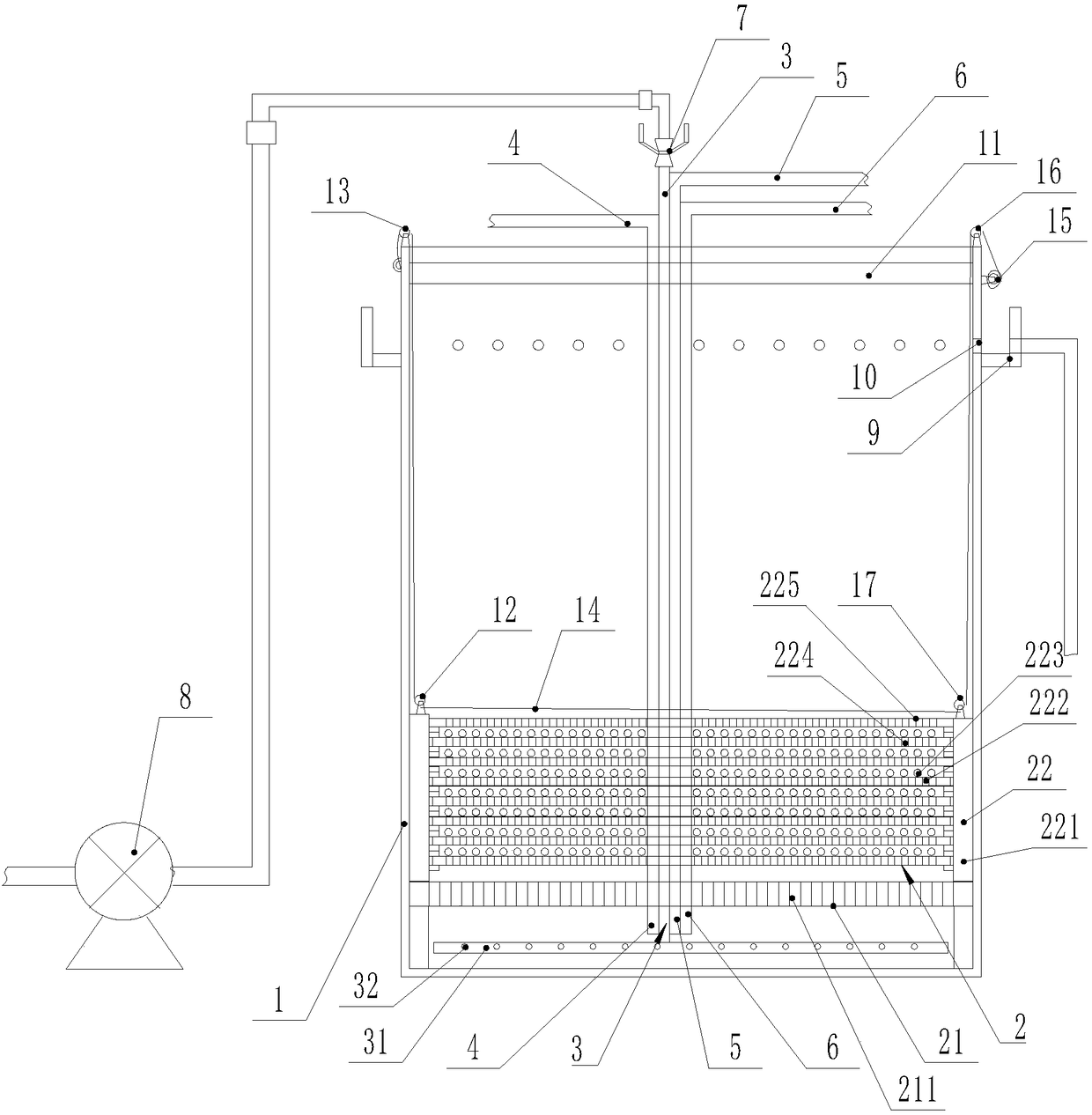

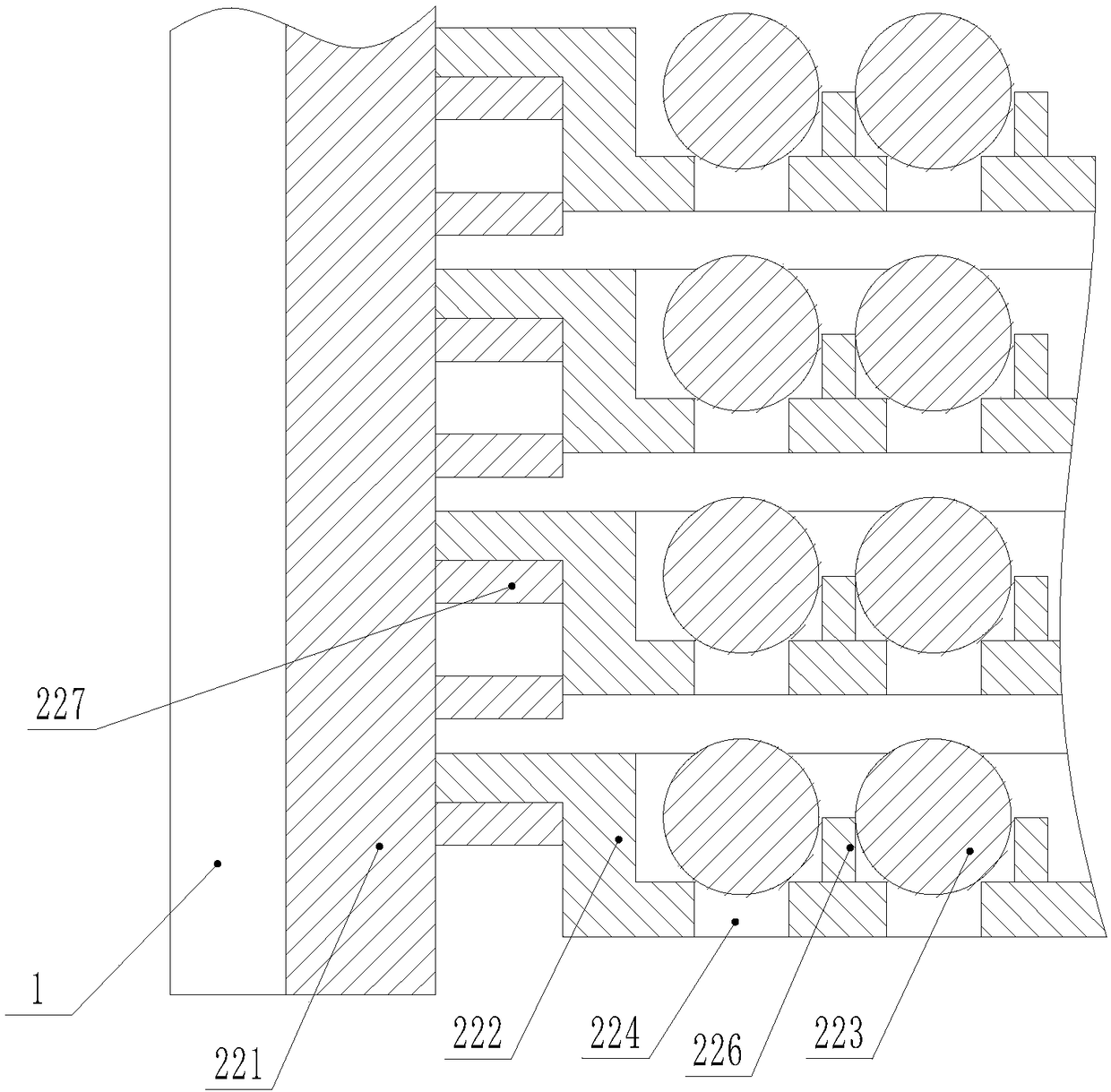

[0078] Such as Figure 1 to Figure 5 As shown, an advanced oxidation water treatment system based on micro-electrolysis, including

[0079] Regulating pond, described regulating pond is provided with water inlet main pipe and water outlet main pipe; Water inlet main pipe can be used to connect the sewage that certain enterprise discharges, and this sewage treatment system can be used for treating the sewage of COD concentration 8000-12000mg / L.

[0080] Alkali-adding pool, the water inlet of the alkali-adding pool is connected with the outlet main pipe of the regulating pool, and the sodium hydroxide adding pipe is also arranged on the described alkali-adding pool; the sodium hydroxide adding pipe is used to connect the sodium hydroxide adding system, through A flow meter is set to determine the amount of alkali added in the alkali adding pool, and of course, a pH value sensor is also arranged in the alkali adding pool to detect the pH value.

[0081] A coagulation tank, the w...

Embodiment 2

[0096] A kind of advanced oxidation water treatment method based on micro-electrolysis, this treatment method is to use above-mentioned treatment system, it comprises the following steps:

[0097] S1. Send the sewage of a certain enterprise into the adjustment tank for deployment, so that the COD concentration of the water in the adjustment tank is 8000mg / L, the ammonia nitrogen concentration is 300mg / L, the total phosphorus is 50mg / L, and the pH=4;

[0098] S2, the prepared sewage is sent into the alkali-adding pool, and sodium hydroxide is added into the alkali-adding pool to make the pH value in the sewage reach 8.5;

[0099] S3, the sewage in the alkali-adding tank flows into the flocculation tank, and adds 10% mass ratio of PAC solution and 0.1% mass ratio of PAM solution to the flocculation tank, wherein the addition of PAC is 100ppm, and the addition of PAM is 1ppm

[0100] S4. Discharging the sewage in the flocculation tank into a settling tank for a sedimentation, sendi...

Embodiment 3

[0110] A kind of advanced oxidation water treatment method based on micro-electrolysis, this treatment method is to use above-mentioned treatment system, it comprises the following steps:

[0111] S1. Send the sewage of a certain enterprise into the adjustment pool for deployment, so that the COD concentration of the water in the adjustment pool is 12000mg / L, the ammonia nitrogen concentration is 500mg / L, the total phosphorus is 100mg / L, and PH=5;

[0112] S2, the prepared sewage is sent into the alkali-adding pool, and sodium hydroxide is added to the alkali-adding pool to make the pH value in the sewage reach 10;

[0113] S3, the sewage in the alkali-adding tank flows into the flocculation tank, and adds 10% mass ratio of PAC solution and 0.1% mass ratio of PAM solution to the flocculation tank, wherein the addition of PAC is 400ppm, and the addition of PAM is 5ppm

[0114] S4. Discharging the sewage in the flocculation tank into a settling tank for a sedimentation, sending ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com