Welding method for friction stir welding of aluminum alloy narrow step lap joint

A technology of friction stir welding and welding method, which is applied in the direction of welding equipment, non-electric welding equipment, metal processing equipment, etc., and can solve the problems of friction stir welding patents and articles without narrow lap joints, reduced cooling efficiency of cold plates, and reduced cooling channels Area and other issues, to achieve the effect of improving the cooling efficiency of the cold plate, improving the cooling efficiency, and improving the design efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

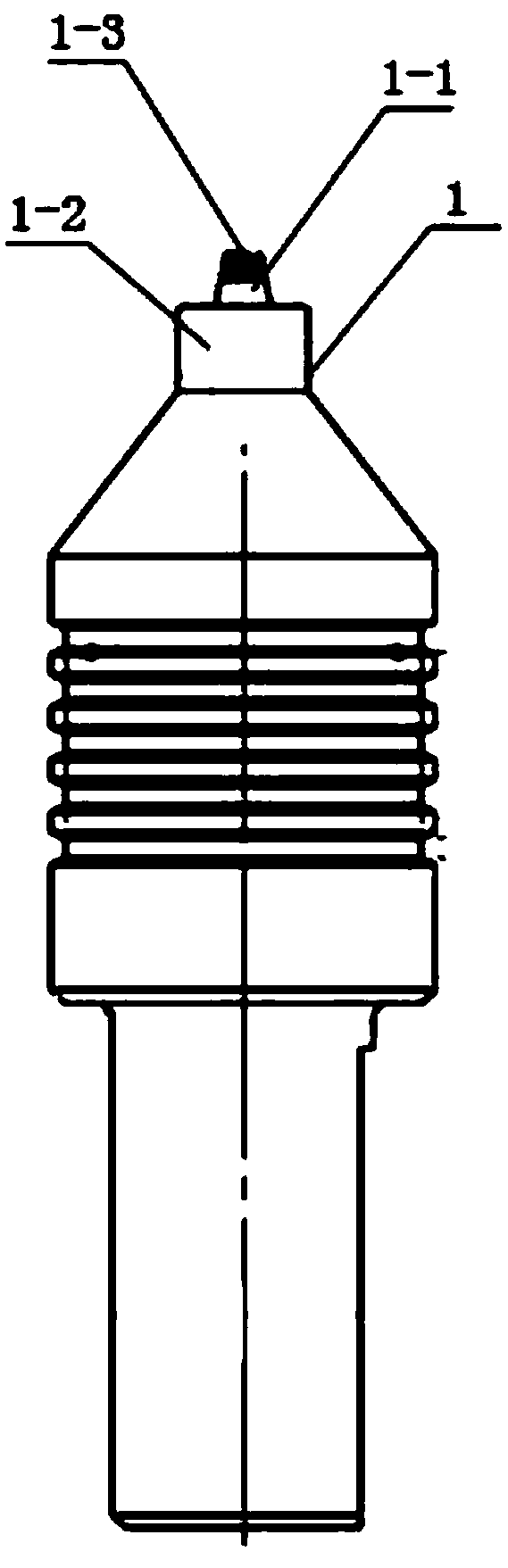

[0026] Example 1, when the welding depth is 4mm, the length of the stirring needle is 4mm, right-handed, the diameter of the tip of the stirring needle is 2.8mm, the diameter of the root of the stirring needle is 4.4mm, the width of the shoulder is 10mm, and the shoulder is concentric. The concave depth is 0.6mm, which is suitable for welding with a welding depth of 4mm and a narrow step lap of aluminum alloy cold plate structure with a step not less than 2mm. The material of the cold plate is T6 state Al-Mg-Si series heat-treatable aluminum alloy. It is: remove the oxide film on the surface of the weld by acid and alkali cleaning before welding, and confirm that there is no burr, no damage, no metal chips and oil on the surface of the weld, the rotation speed of the rotary head is 1200-1500r / min, and the welding speed is 100-120mm / min, the inclination angle of the stirring head is 2.5°, and the friction welding is carried out to make the weld without defects, such as figure...

Embodiment 2

[0027] Example 2, when the welding depth is 5mm, the length of the stirring needle is 5mm, right-handed, the diameter of the tip of the stirring needle is 3.2mm, the diameter of the root of the stirring needle is 5.4mm; the width of the shoulder is 12mm, and the shoulder is concentric and concave The depth is 0.6mm, which is suitable for welding with a welding depth of 5mm and a narrow step of not less than 3mm to lap the aluminum alloy cold plate structure. The material of the cold plate is T6 state Al-Mg-Si series heat-treatable aluminum alloy. The welding steps are: : Remove the oxide film on the surface of the weld by acid and alkali cleaning before welding, confirm that the surface of the weld is free of burrs, damage, metal shavings and oil, the rotation speed of the stirring head is 1000-1200r / min, and the welding speed is 100-120mm / min , the inclination angle of the stirring head is 2.5°, and the friction welding is carried out to make the weld without defects, such as ...

Embodiment 3

[0028] Example 3, when the welding depth is 6mm, the length of the stirring needle is 6mm, right-handed, the diameter of the tip of the stirring needle is 3.4mm, the diameter of the root of the stirring needle is 6.5mm, the width of the shoulder is 12mm, the shoulder is concentric and concave The depth is 0.63mm, which is suitable for welding aluminum alloy cold plate structures with narrow steps with a welding depth of 6mm and a step not less than 4mm. No burrs, no damage, no metal shavings and oil stains, the rotation speed of the stirring head is 600-800r / min, the welding speed is 80-100mm / min, the inclination angle of the stirring head is 2.5°, and the friction welding is carried out so that the weld seam has no defects. Such as Figure 4 shown.

[0029] The beneficial effect of the present invention is: adopt narrow step lap joint (the step width is obviously smaller than the weld seam depth) friction stir welding stirring head, research and develop new narrow lap joint ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com