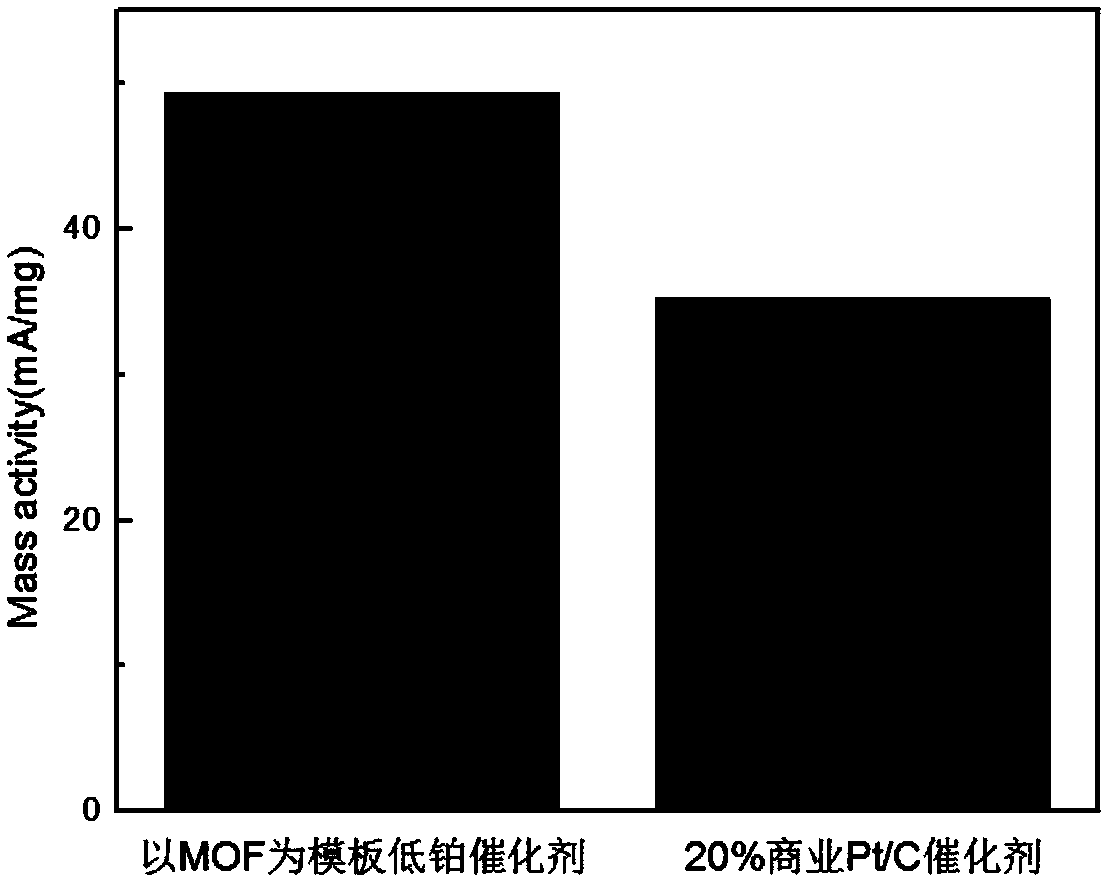

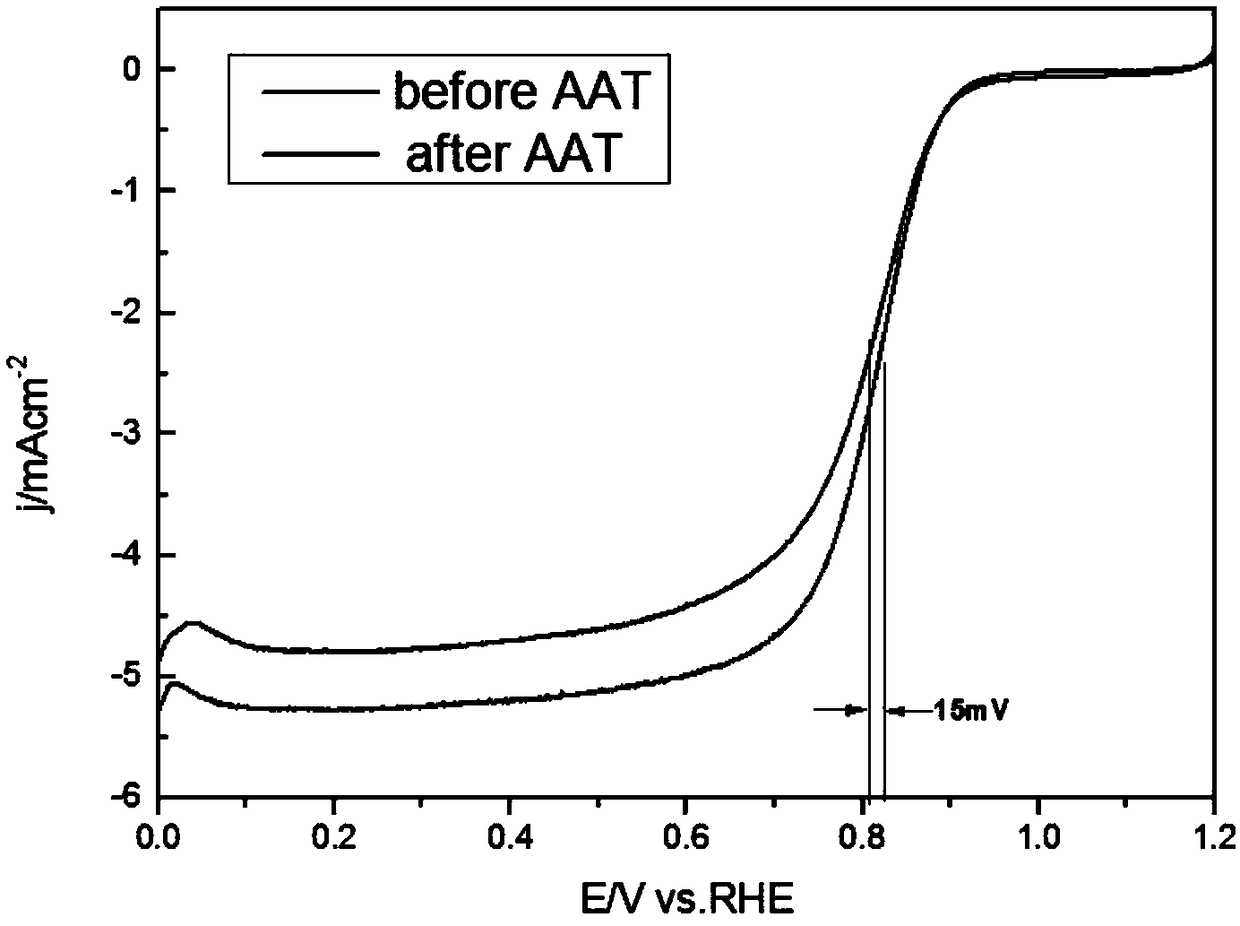

Method for preparing low Pt loading capacity type fuel battery catalyst by utilizing MOF as template

A technology for fuel cells and catalysts, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as restricting applications, and achieve the effects of reducing growth and movement, slowing migration and agglomeration, and improving mass activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of preparation method of the fuel cell catalyst with low Pt loading of MOF as template, comprises the following steps:

[0032] Step 1) Preparation of MOF template: Cobalt nitrate, 2-aminoterephthalic acid and triethylenediamine (concentration ratio=1:0.7:0.7) were dispersed in N,N-dimethylformamide (DMF) to form MOF precursor mixed solution, transfer the above mixed solution to a high-pressure reactor, and use the solvothermal method to stand in an oven at 110-130°C for 24-48 hours, then collect the MOF crystal precipitate, and centrifuge and wash the MOF precipitate three to five times. Vacuum drying to obtain MOF powder for later use;

[0033] Step 2) Pt loading on MOF template: Add MOF powder to 0.01-0.2mol / L sodium chloroplatinate ethanol solution and stir for 20-60min, then let it stand at 0-10℃ for 24h, take it out, and wash it by centrifugation for three After five times, the MOF material impregnated with Pt was obtained by vacuum drying;

[0034] Step ...

Embodiment 2

[0040] A kind of preparation method of the fuel cell catalyst with low Pt loading of MOF as template, comprises the following steps:

[0041] Step 1) Preparation of MOF template: Cobalt nitrate, 2-aminoterephthalic acid and triethylenediamine (concentration ratio=1:1:0.5) were dispersed in N,N-dimethylformamide (DMF) to form MOF precursor mixed solution, transfer the above mixed solution to a high-pressure reactor, and use the solvothermal method to stand in an oven at 110-130°C for 24-48 hours, then collect the MOF crystal precipitate, and centrifuge and wash the MOF precipitate three to five times. Vacuum drying to obtain MOF powder for later use;

[0042] Step 2) Pt loading on MOF template: Add MOF powder to 0.01-0.2mol / L sodium chloroplatinate ethanol solution and stir for 20-60min, then let it stand at 0-10℃ for 24h, take it out, and wash it by centrifugation for three After five times, vacuum dry for later use;

[0043] Step 3) Preparation of catalyst with low Pt loadi...

Embodiment 3

[0045] A kind of preparation method of the fuel cell catalyst with low Pt loading of MOF as template, comprises the following steps:

[0046] Step 1) Preparation of MOF template: Cobalt nitrate, 2-aminoterephthalic acid and triethylenediamine (concentration ratio=1:1:0.7) were dispersed in N,N-dimethylformamide (DMF) to form MOF precursor mixed solution, transfer the above mixed solution to a high-pressure reactor, and use the solvothermal method to stand in an oven at 110-130°C for 24-48 hours, then collect the MOF crystal precipitate, and centrifuge and wash the MOF precipitate three to five times. Vacuum drying to obtain MOF powder for later use;

[0047] Step 2) Pt loading on MOF template: Add MOF powder to 0.01-0.2mol / L sodium chloroplatinate ethanol solution and stir for 20-60min, then let it stand at 0-10℃ for 24h, take it out, and wash it by centrifugation for three After five times, vacuum dry for later use.

[0048] Step 3) Preparation of catalysts with low Pt load...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com