MnZn power ferrite for MHz-level switching mode power supply and preparation method of MnZn power ferrite

A switching power supply and ferrite technology, which is applied in the manufacture of inductors/transformers/magnets, circuits, electrical components, etc., can solve the problems of high sintering temperature and high material loss, and achieve low sintering temperature, reduced loss, and low power loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

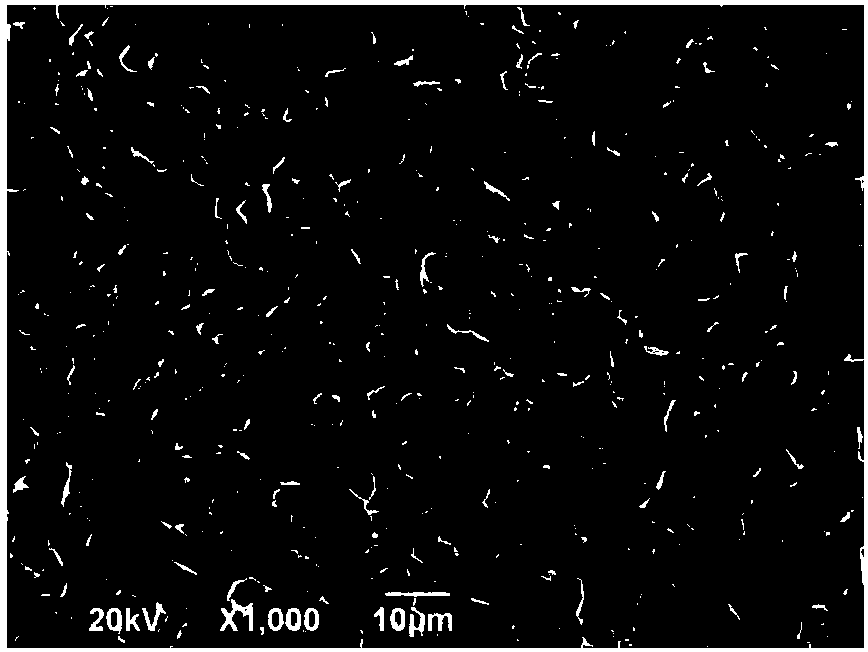

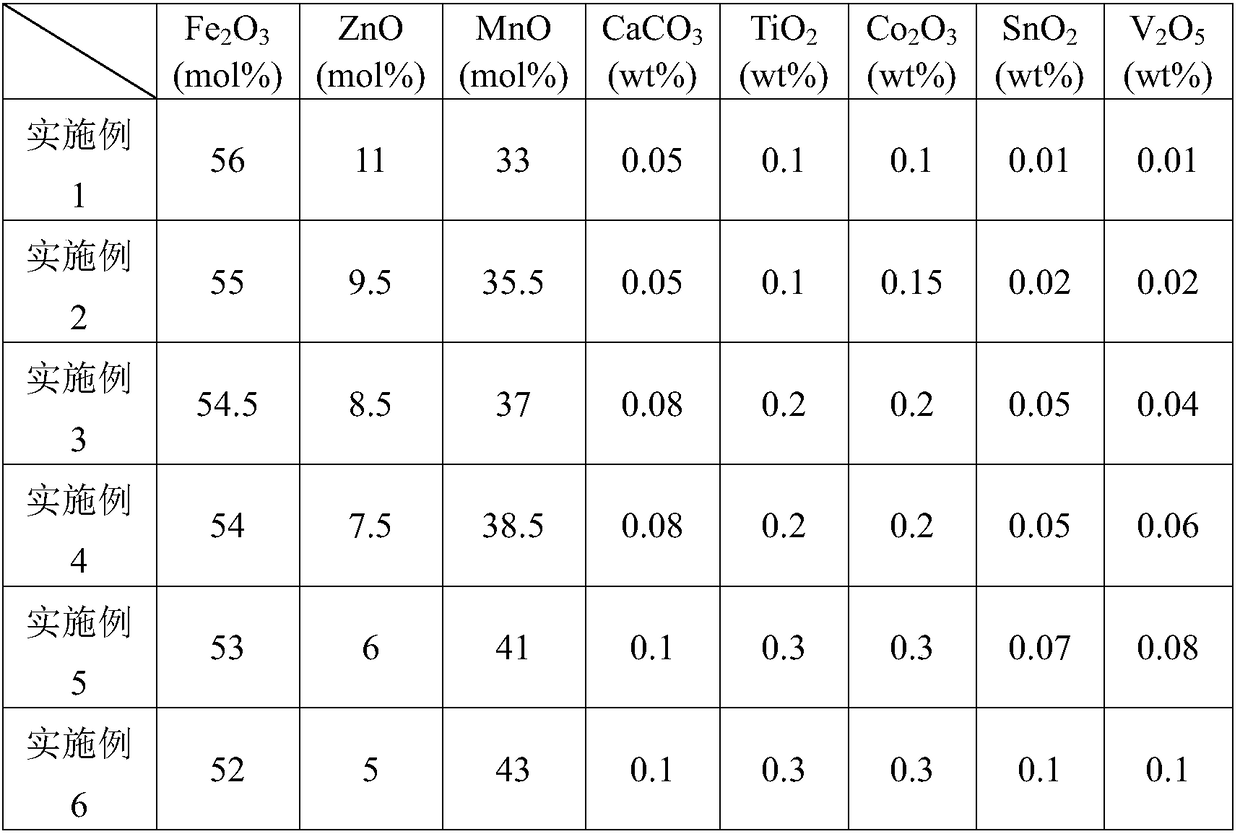

[0041] The high-frequency low-loss MnZn power ferrite material is composed of main materials and dopants. The main materials are calculated by mole percentage and calculated by oxides, including:

[0042] 52~56mol% Fe 2 o 3 , 5-11 mol% ZnO, 33-43 mol% MnO.

[0043] Dopants are calculated as oxides by weight percentage, including:

[0044] 0.05~0.1wt%CaCO 3 , 0.1~0.3wt% TiO 2 , 0.1~0.3wt% Co 2 o 3 , 0.01~0.1wt% SnO 2 , 0.01~0.1wt%V 2 o 5 .

[0045] The preparation method of high-frequency low-loss MnZn power ferrite material comprises the following steps:

[0046] (1) Main ingredient formula

[0047] Using 52~56mol% Fe 2 o 3 , 5 ~ 11mol% ZnO, 33 ~ 43mol% MnO;

[0048] (2) Ball milling once

[0049] Put the above powder into a ball mill, add equal weight deionized water, and ball mill for 2 hours

[0050] (3) pre-burning

[0051] Dry the ball mill material obtained in step (2), and pre-fire it in a furnace at 920°C for 2 hours;

[0052] (4) Doping

[0053] Add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com