Black wattle bark extract for treating II type diabetes and application thereof in preparation of medicine for treating II type diabetes

A technology of black wattle bark and extract, which is applied in the direction of drug combination, medical preparations containing active ingredients, metabolic diseases, etc., and can solve the problem that carbohydrates cannot be decomposed in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

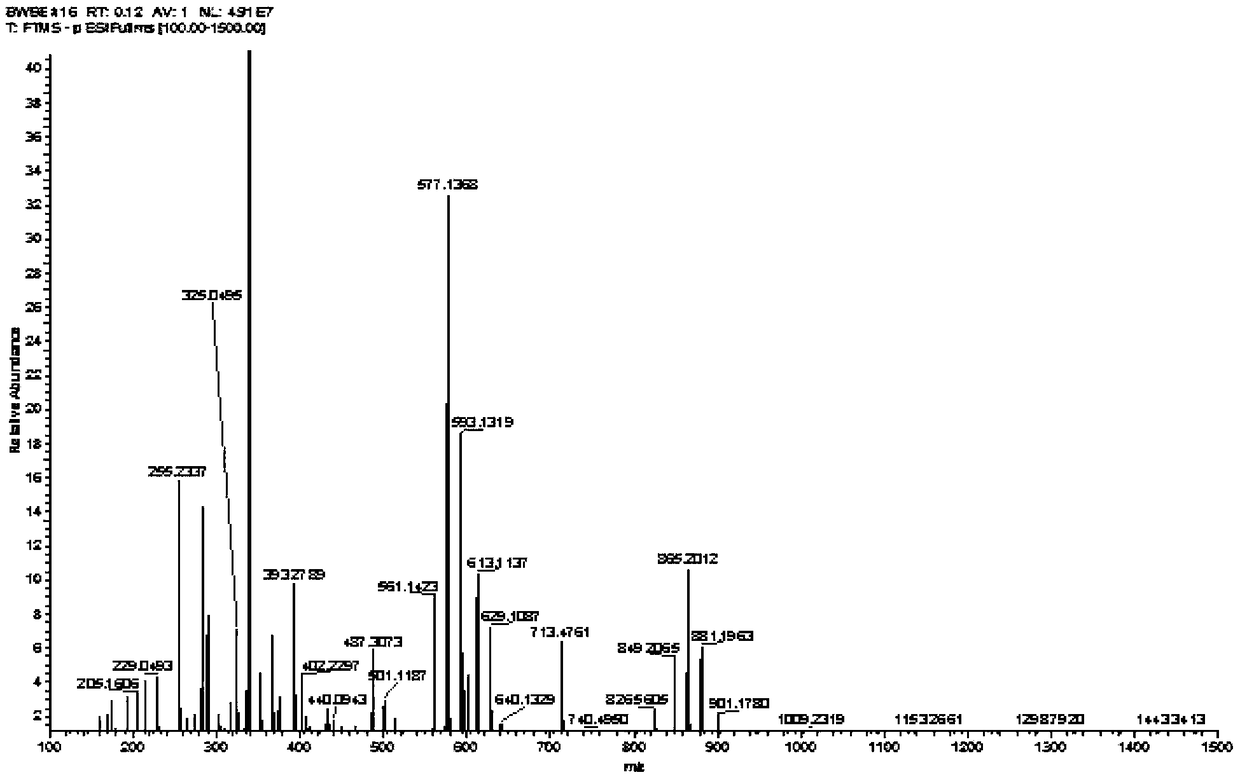

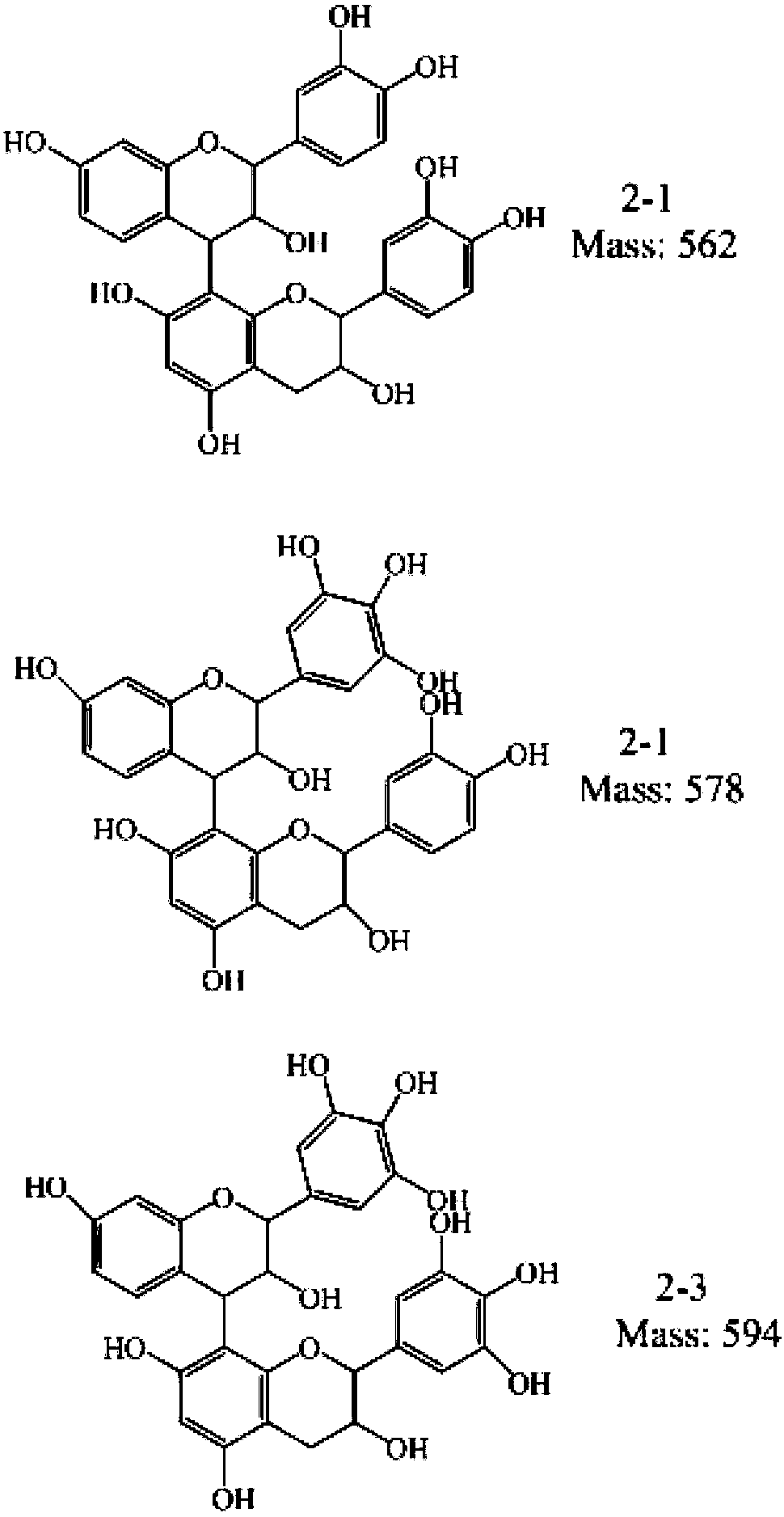

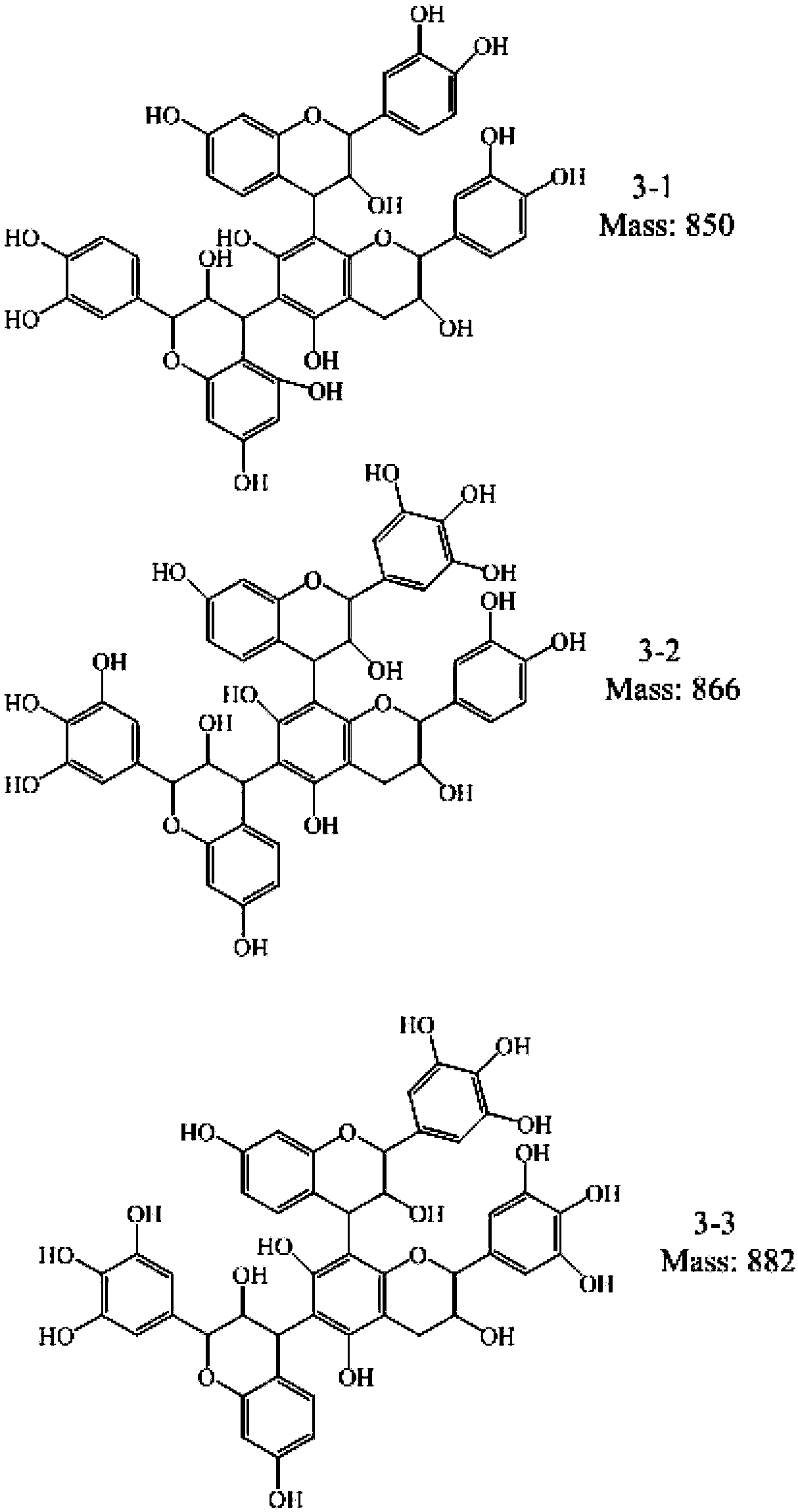

Image

Examples

Embodiment 1

[0039] Mix and soak 30g black wattle bark with 90 meshes and 180mL n-hexane for 130min (stir with 100rpm rotating speed during soaking), filter to obtain filter residue, mix filter residue with 220mL n-hexane and soak for 50min, filter to obtain defatted black wattle Skin.

[0040] The obtained defatted black wattle bark is mixed with 45% acetone by volume fraction (the mass of the defatted black wattle bark and the solid-liquid ratio of 45% by volume fraction are 1Kg:11L of acetone), at 50 ℃, ultrasonic at 45KHz Extract for 0.5h and filter to obtain the first extract and the first filter residue. The first filter residue is mixed with 75% acetone by volume fraction (the mass of defatted black wattle bark and the solid-liquid ratio of 75% acetone by volume fraction is 1Kg:9L), ultrasonically leached for 1h at 50°C and 45KHz , to obtain the second extract. The first and second extracts were combined, and after being rotary evaporated to dryness at 35°C, the rotary evaporated ...

Embodiment 2

[0042] Mix and soak 30g black wattle bark with a particle size of 100 mesh and 200mL n-hexane for 120min (stirring at a speed of 150rpm during the soaking process), filter to obtain a filter residue, mix and soak the filter residue and 200mL n-hexane for 60min, filter to obtain defatted black wattle Skin.

[0043] The obtained defatted black wattle bark is mixed with 70% acetone by volume fraction (the mass of the defatted black wattle bark is 1Kg:11L with a volume fraction of 70% acetone), ultrasonic at 50°C at 45KHz Extract for 0.5h and filter to obtain the first extract and the first filter residue. The first filter residue is mixed with 70% acetone by volume fraction (the mass of defatted black wattle bark and the solid-liquid ratio of 70% volume fraction by acetone are 1Kg:10L), at 50 ℃, 0.5 h, to obtain the second extraction solution. The first and second extracts were combined, and after being rotary evaporated to dryness at 45°C, the rotary evaporated solution was va...

Embodiment 3

[0045] Mix and soak 30g black wattle bark with a particle size of 110 mesh and 180mL n-hexane for 110min (stir at a speed of 200rpm during the soaking process), filter to obtain a filter residue, mix the filter residue and 180mL n-hexane and soak for 50min, filter to obtain defatted black wattle Skin.

[0046] The obtained defatted black wattle bark and water (the mass of the defatted black wattle bark and the solid-liquid ratio of water are 1 Kg:9L), at 50 ℃, 45KHz ultrasonic leaching 0.5h, filter, obtain the first leaching Extract and first filter residue. The first filter residue was mixed with water (the mass-to-water ratio of defatted black wattle bark to water was 1 Kg:9L), and ultrasonically leached at 50°C and 45KHz for 0.75h to obtain the second extract. The first and second extracts were combined, and after rotary evaporation at 50°C to dryness, the rotary evaporation liquid was vacuum freeze-dried at -37°C for 22 h to obtain the black wattle bark extract.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com