Electrode binding agent of novel lithium ion battery and preparation method of electrode binding agent

A lithium-ion battery and binder technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of unsuitable application of positive electrodes, limited scope of application, lack of elasticity, etc., and achieve small electrode polarization and binder The effect of low interface impedance and high capacity retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] (3) Preparation of electrodes

[0052] With super P li as the conductive agent, lithium iron phosphate (LiFePO 4 ) and nano-silicon (Si) as the active material, (meth)acrylic acid-acrylate block copolymer (PAr-b-PAA-b-PAr) as the electrode binder, dioxane and deionized water as the dispersed Medium, according to the mass ratio of lithium iron phosphate electrode LiFePO 4 : super P li: AA-b-Ar=8:1:1, silicon electrode mass ratio Si: super P li: PAr-b-PAA-b-PAr=6.3: 2.2: 1.5 to prepare electrode slurry, phosphoric acid The lithium iron slurry was coated on aluminum foil, the silicon slurry was coated on copper foil, and dried in a vacuum oven at 120°C.

[0053] (4) Battery assembly and electrochemical performance testing

[0054] a) Battery assembly

[0055] The battery assembly uses lithium iron phosphate electrode and silicon electrode as the positive electrode, and the negative electrode is lithium sheet. Celgard2400 separator and LB315 electrolyte are used to asse...

Embodiment 1

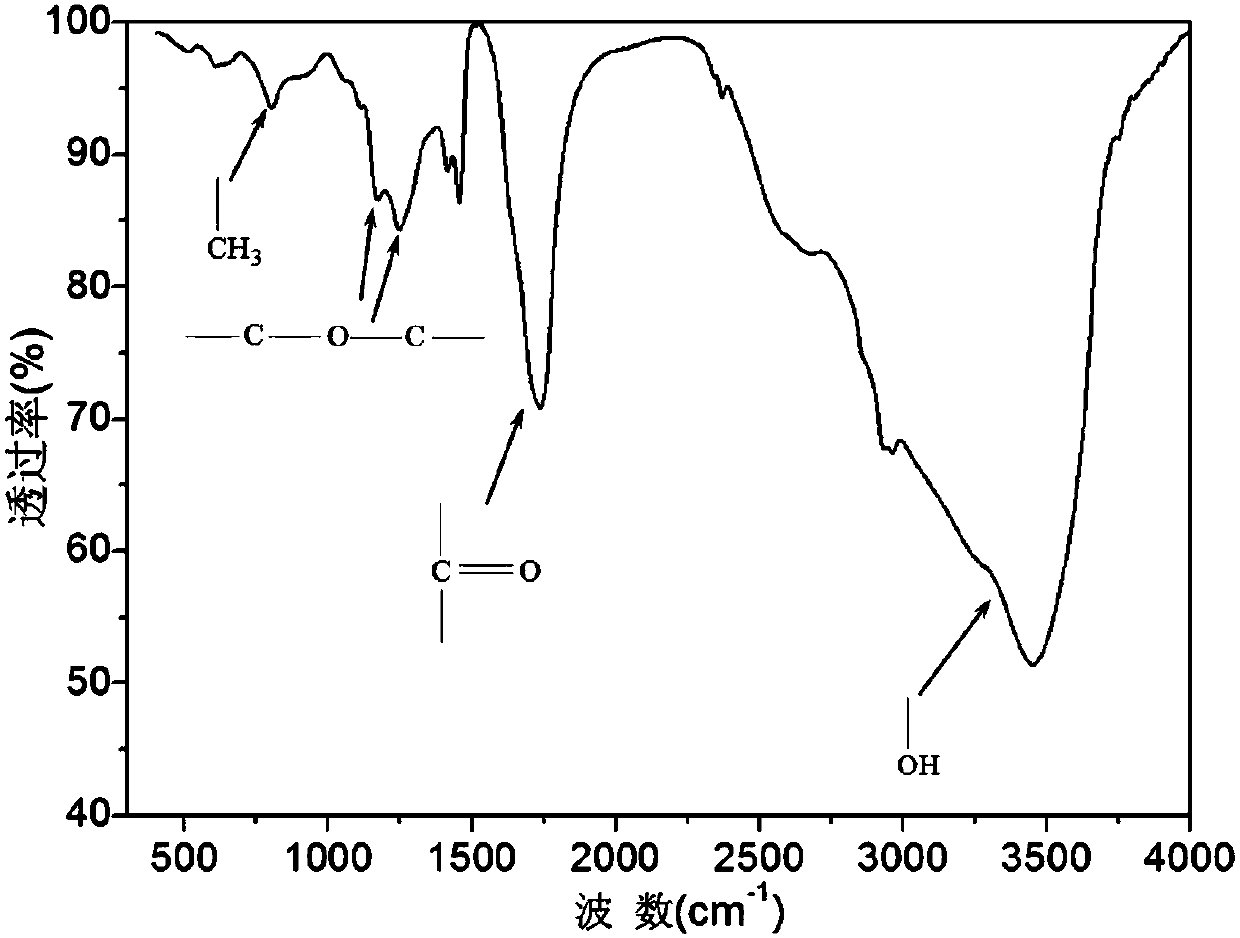

[0061] The present embodiment provides a kind of electrode binder of novel lithium ion battery, and its structural formula is

[0062] R-AA n1 -b-MA n2 -b-AA n3 -X, the molecular weight of the designed polymer is 15K-30K-15K.

[0063] (1) 0.5 parts by weight of amphiphilic macromolecular reversible addition fragmentation chain transfer reagent (1) and 0.05 parts by weight of BPO are stirred and dissolved in 80 parts by weight of dioxane, and then 20 parts by weight of acrylic acid monomer ( AA) was poured into the reactor and stirred and mixed, and deoxygenated with nitrogen at room temperature for 5 minutes, then the reaction temperature was raised to 80°C, kept stirring, and after polymerization for 3 hours, R-AA was obtained n1 -X polymer solution;

[0064] (2) After the first step of reaction is completed, add 40 parts by weight of MA monomer and 80 parts by weight of dioxane dissolved with 0.05 parts by weight of BPO, pass nitrogen to remove oxygen for 5 minutes at ro...

Embodiment 2

[0072] This embodiment provides a novel lithium-ion battery electrode binder, its structural formula is: R-AA n1 -b-MA n2 -b-AA n3 -X, the molecular weight of each section is designed to be 81K-18K-81K:

[0073] (1) 0.1 parts by weight of amphiphilic macromolecular reversible addition fragmentation chain transfer reagent (2) and 0.005 parts by weight of V501 are stirred and dissolved in 80 parts by weight of dioxane, and then 20 parts by weight of acrylic acid monomer ( AA) was poured into the reactor and stirred and mixed, and deoxygenated with nitrogen at room temperature for 30 minutes, then the reaction temperature was raised to 60°C, kept stirring, and after polymerization for 20 hours, R-AA was obtained n1 -X polymer solution;

[0074] (2) After the first step reaction, add 5 parts by weight of MA monomer and 20 parts by weight of dioxane dissolved with 0.005 parts by weight of V501, pass nitrogen to remove oxygen for 30 minutes at room temperature, then raise the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com