Preparation method of ZnO/C nano composite microsphere material with capsule structure

A technology of nanocomposite and composite materials, which is applied in the field of preparation of capsule structure ZnO/C nanocomposite microsphere materials, can solve the problems of small progress and achieve the effect of improving Coulombic efficiency, reducing the generation of SEI film and improving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

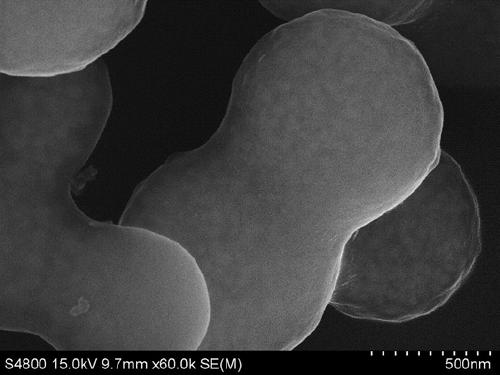

Image

Examples

Embodiment 1

[0020] (1) Under stirring conditions, prepare a mixed aqueous solution of zinc chloride, resorcinol, formaldehyde and hydrochloric acid. The concentrations of zinc chloride, resorcinol, formaldehyde and hydrochloric acid in the solution are 0.1 mol / L and 0.6 mol respectively / L, 1.2 mol / L and 0.06 mol / L, at 80 o Gel was obtained after reacting for 3 h under the water bath condition of C, and dried to obtain xerogel;

[0021] (2) Calcining the xerogel in an air atmosphere at a temperature of 387 o C, the heating rate is 2.5 o C / min, the calcination time is 4 h;

[0022] (3) The product obtained in step (2) is calcined in an argon atmosphere, and the calcining temperature is 750 o C, the calcination time is 3 h, and the capsule structure ZnO / C nanocomposite microsphere material is prepared.

[0023] In the capsule structure ZnO / C nanocomposite microsphere material of the present embodiment, the mass fraction of contained ZnO is 90%, and the mass fraction of contained amorpho...

Embodiment 2

[0027] (1) Under stirring conditions, prepare a mixed aqueous solution of zinc chloride, resorcinol, formaldehyde and hydrochloric acid. The concentrations of zinc chloride, resorcinol, formaldehyde and hydrochloric acid in the solution are 0.3 mol / L and 0.4 mol respectively / L, 0.8 mol / L and 0.06 mol / L, at 80 o Gel was obtained after reacting for 3 h under the water bath condition of C, and dried to obtain xerogel;

[0028] (2) Calcining the xerogel in an air atmosphere at a temperature of 387 o C, the heating rate is 2.5 o C / min, the calcination time is 5 h;

[0029] (3) The product obtained in step (2) is calcined in an argon atmosphere, and the calcining temperature is 750 o C, the calcination time is 3 h, and the capsule structure ZnO / C nanocomposite microsphere material is prepared.

[0030] In the capsule structure ZnO / C nanocomposite microsphere material of the present embodiment, the mass fraction of contained ZnO is 95%, and the mass fraction of amorphous C conta...

Embodiment 3

[0034] (1) Under stirring conditions, prepare a mixed aqueous solution of zinc chloride, resorcinol, formaldehyde and hydrochloric acid. The concentrations of zinc chloride, resorcinol, formaldehyde and hydrochloric acid in the solution are 0.1 mol / L and 0.8 mol respectively / L, 1.6 mol / L and 0.06 mol / L, at 80 o Gel was obtained after reacting for 3 h under the water bath condition of C, and dried to obtain xerogel;

[0035] (2) Calcining the xerogel in an air atmosphere at a temperature of 375 o C, the heating rate is 2.5 o C / min, the calcination time is 3 h;

[0036] (3) The product obtained in step (2) is calcined in an argon atmosphere, and the calcining temperature is 800 o C, the calcination time is 3 h, and the capsule structure ZnO / C nanocomposite microsphere material is prepared.

[0037] In the capsule structure ZnO / C nanocomposite microsphere material of the present embodiment, the mass fraction of contained ZnO is 80%, and the mass fraction of amorphous C conta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com