Silicon nanometer layer graphite composite heterojunction material and preparation method and application thereof

A composite heterojunction and silicon nanotechnology, which is applied in the field of lithium-ion batteries, can solve the problems of affecting material consistency cycle stability, affecting electrode cycle stability, and limiting wide application, achieving high energy density, alleviating expansion, and improving energy efficiency. The effect of transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

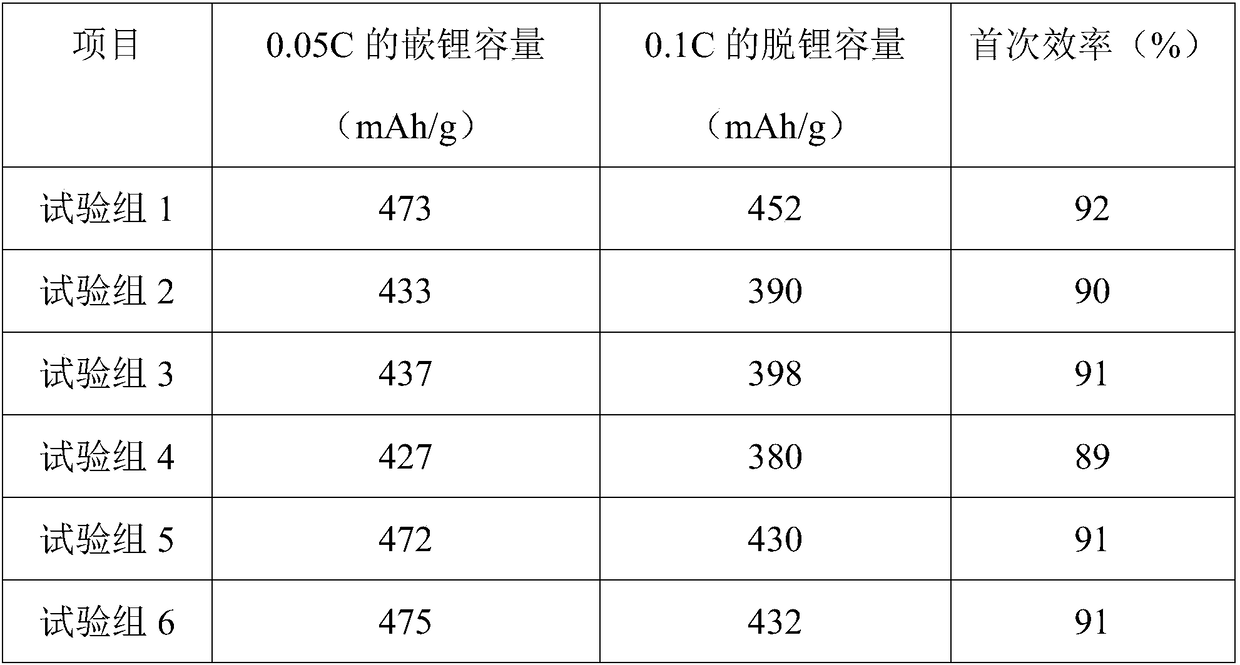

Examples

Embodiment 1

[0032] A silicon nano-layer graphite composite heterojunction material is characterized in that it includes an inner core and an outer layer, the inner core is graphite, and the outer layer is a silicon nano-layer;

[0033] Wherein, the average thickness of the silicon nanolayer is 100 nm; the graphite is artificial graphite; the diameter of the graphite is 1.5 μm; the mass ratio of the silicon nanolayer to graphite is 1:10.

[0034] The preparation method of the silicon nanolayer graphite composite heterojunction material comprises the following steps:

[0035] S1, mix 9g of graphite and 1g of nickel chloride solution evenly, adjust the pH to 4, then heat under reflux, and centrifuge to obtain sample a in which nickel is adsorbed on the surface of graphite;

[0036] S2. Pass hydrogen gas into sample a, heat at 1300° C. for 5 h, carry out hydrogenation reaction, form edge activation sites on the graphite layer, and obtain sample b;

[0037] S3. At a temperature of 1000°C, pas...

Embodiment 2

[0039] A silicon nano-layer graphite composite heterojunction material is characterized in that it includes an inner core and an outer layer, the inner core is graphite, and the outer layer is a silicon nano-layer;

[0040] Wherein, the average thickness of the silicon nanolayer is 10 nm; the graphite is artificial graphite; the diameter of the graphite is 4.5 μm; the mass ratio of the silicon nanolayer to graphite is 1:1.

[0041] The preparation method of the silicon nanolayer graphite composite heterojunction material comprises the following steps:

[0042] S1, mix 9g of graphite and 1g of nickel chloride solution evenly, adjust the pH to 4, then heat under reflux, and centrifuge to obtain sample a in which nickel is adsorbed on the surface of graphite;

[0043] S2. Pass hydrogen gas into sample a, heat at 800° C. for 3 hours, carry out hydrogenation reaction, form edge activation sites on the graphite layer, and obtain sample b;

[0044] S3. At a temperature of 800°C, pas...

Embodiment 3

[0046] A silicon nano-layer graphite composite heterojunction material is characterized in that it includes an inner core and an outer layer, the inner core is graphite, and the outer layer is a silicon nano-layer;

[0047] Wherein, the average thickness of the silicon nanolayer is 80nm; the graphite is natural graphite; the diameter of the graphite is 2.5 μm; the mass ratio of the silicon nanolayer to graphite is 1:7.

[0048] The preparation method of the silicon nanolayer graphite composite heterojunction material comprises the following steps:

[0049] S1, mix 8.5g of graphite and 1.5g of nickel nitrate solution evenly, adjust the pH to 4, then heat under reflux, and centrifuge to obtain sample a in which nickel is adsorbed on the graphite surface;

[0050] S2. Introduce hydrogen into sample a, heat at 1300° C. for 3 hours, carry out hydrogenation reaction, and form edge activation sites on the graphite layer, that is, obtain sample b;

[0051] S3. At a temperature of 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com