Flexible controllable clutch transmission

A technology for transmissions and clutches, applied in transmissions, belts/chains/gears, fluid transmissions, etc., can solve the problems of reduced comfort, frustration, and impact of transmission components, and avoid high heat, wear, and shifting The effect of fast downshift speed and simple shift control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

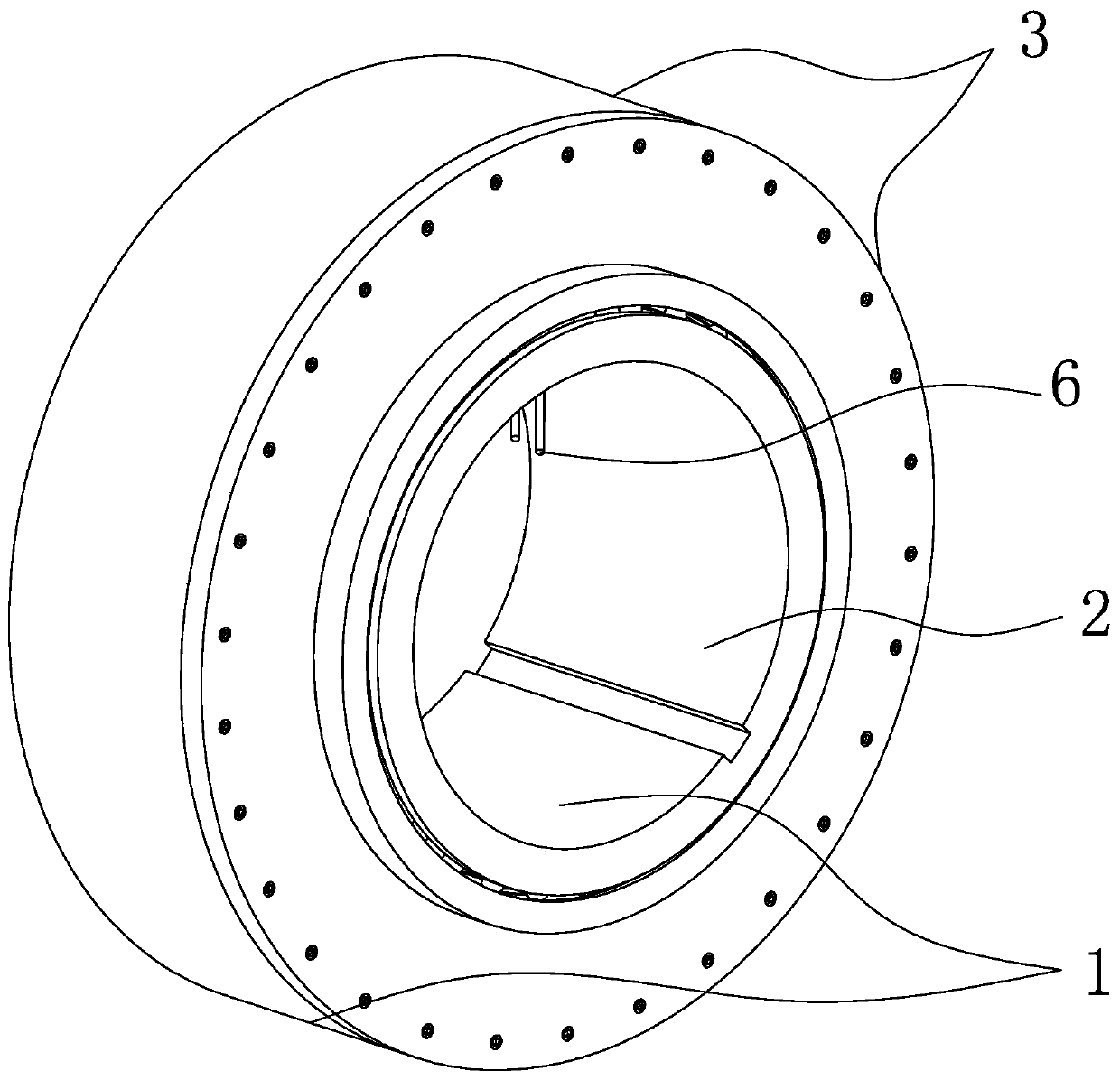

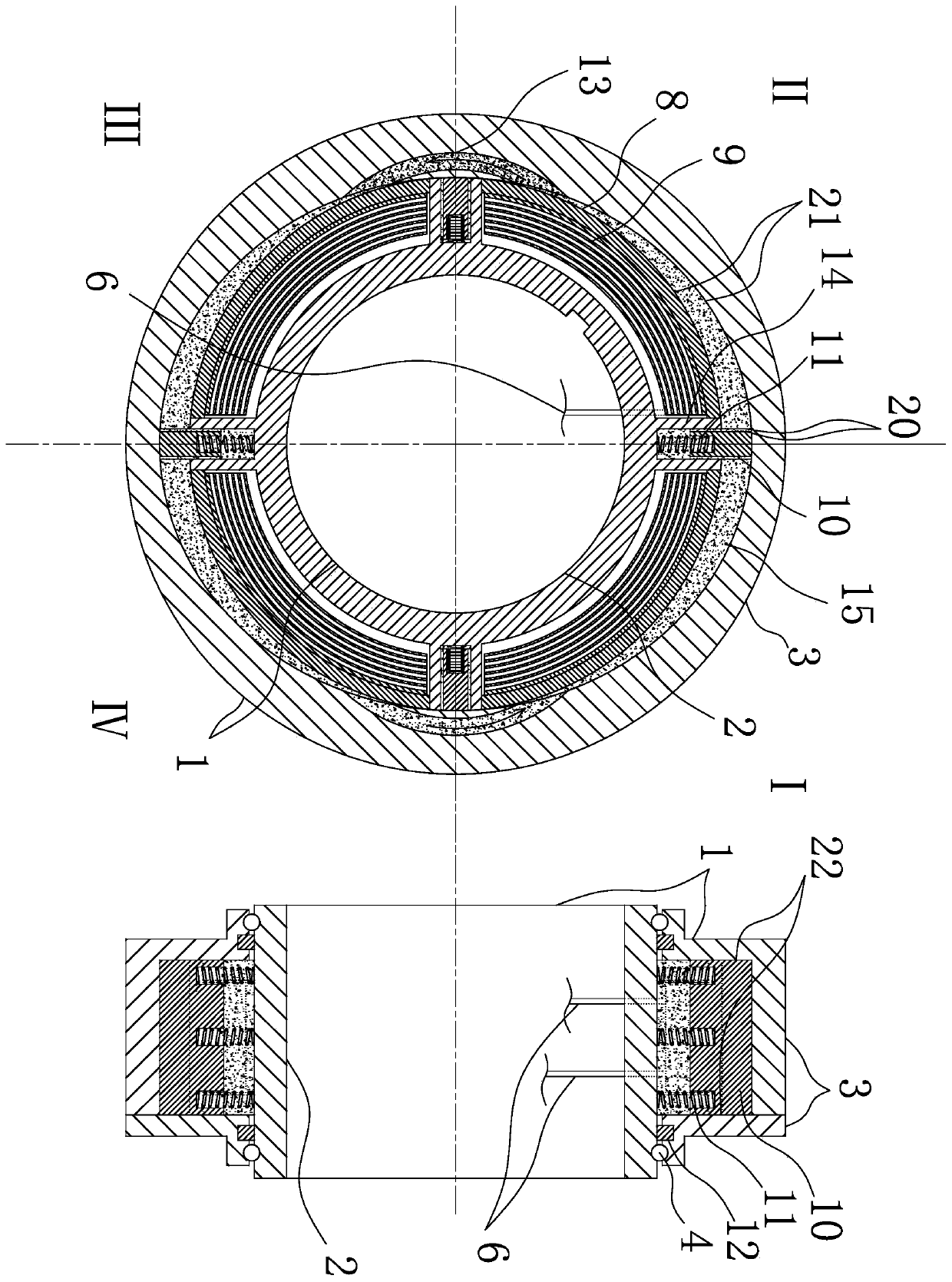

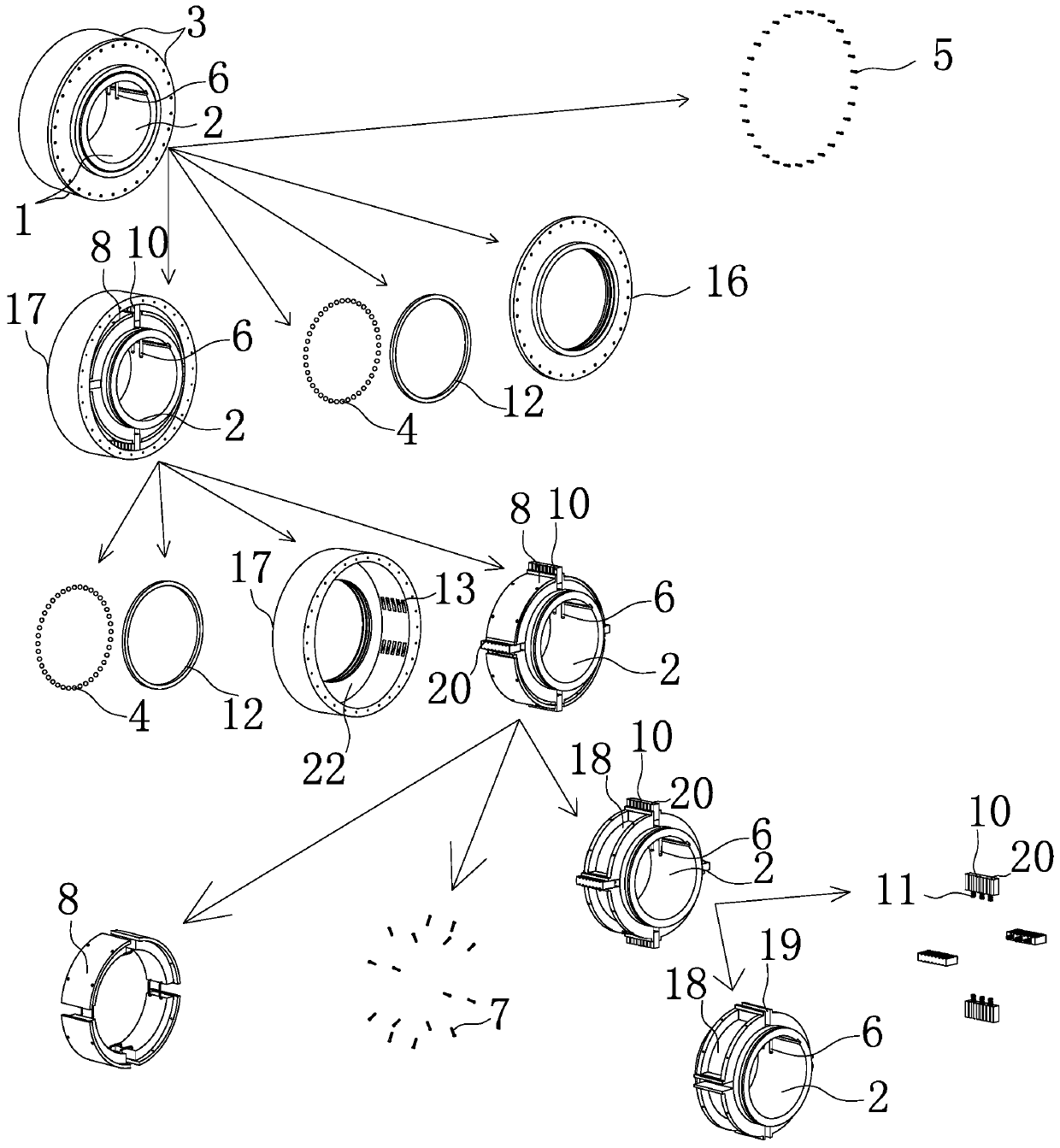

[0022] Embodiments of the present invention will be further described below with reference to the accompanying drawings.

[0023] Such as Figure 1-9 As shown, a flexible controllable clutch transmission has: a flexible controllable clutch 1, a transmission gear 56, a transmission input shaft 31, a transmission output shaft 32 and a transmission housing 26, and is characterized in that the structure of the flexible controllable clutch 1 is : the passive sleeve 3 is socketed on the active sleeve 2, the outer cylindrical surface of the active sleeve 2 is provided with a blade 10 capable of radial movement and a blade movable groove 14, and a blade return spring 11 is arranged in the blade movable groove 14, The inner end faces 22 of the two axial end faces of the passive sleeve 3 are movably connected with the outer end faces of the blades 10 and the axial ends of the blade movable groove 14; The two end faces of the short axis of the surface are connected with the outer cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com