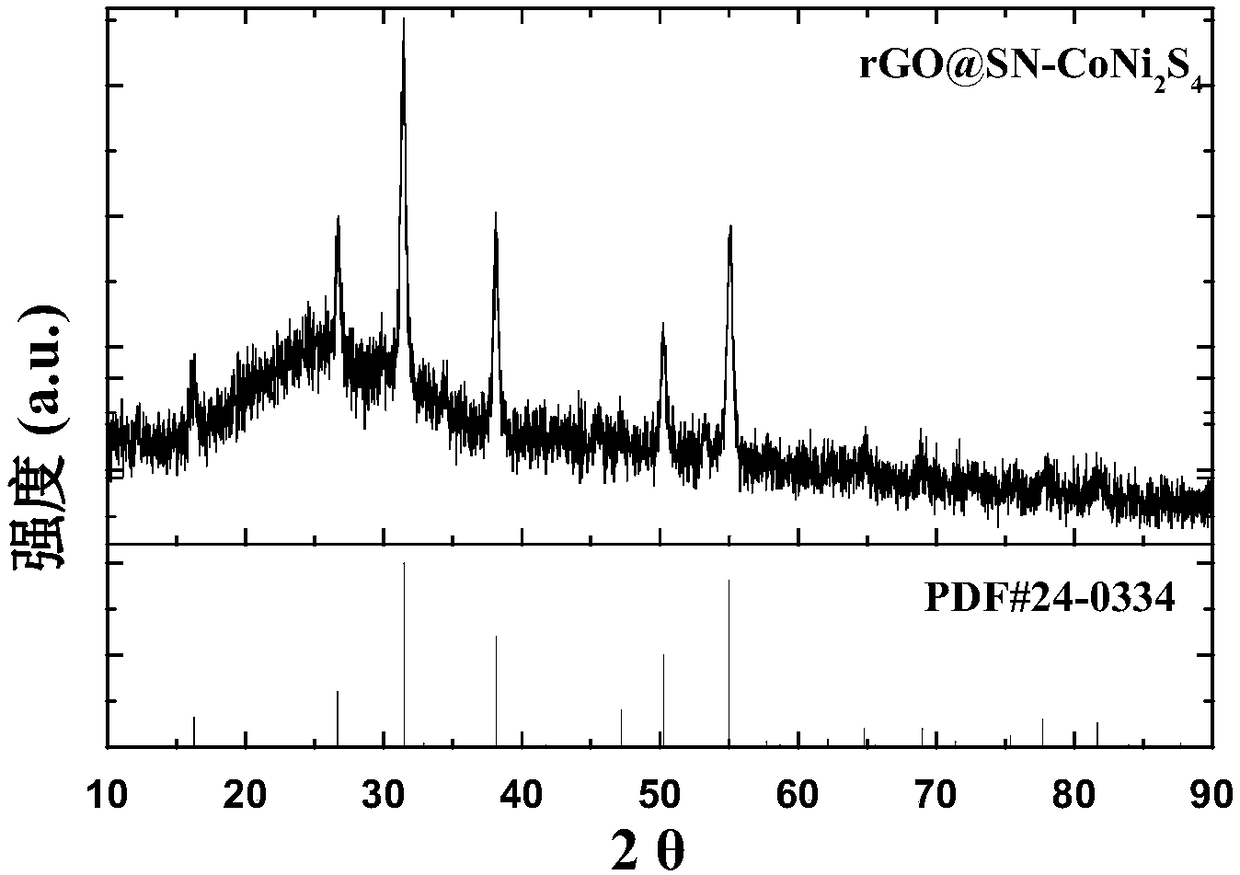

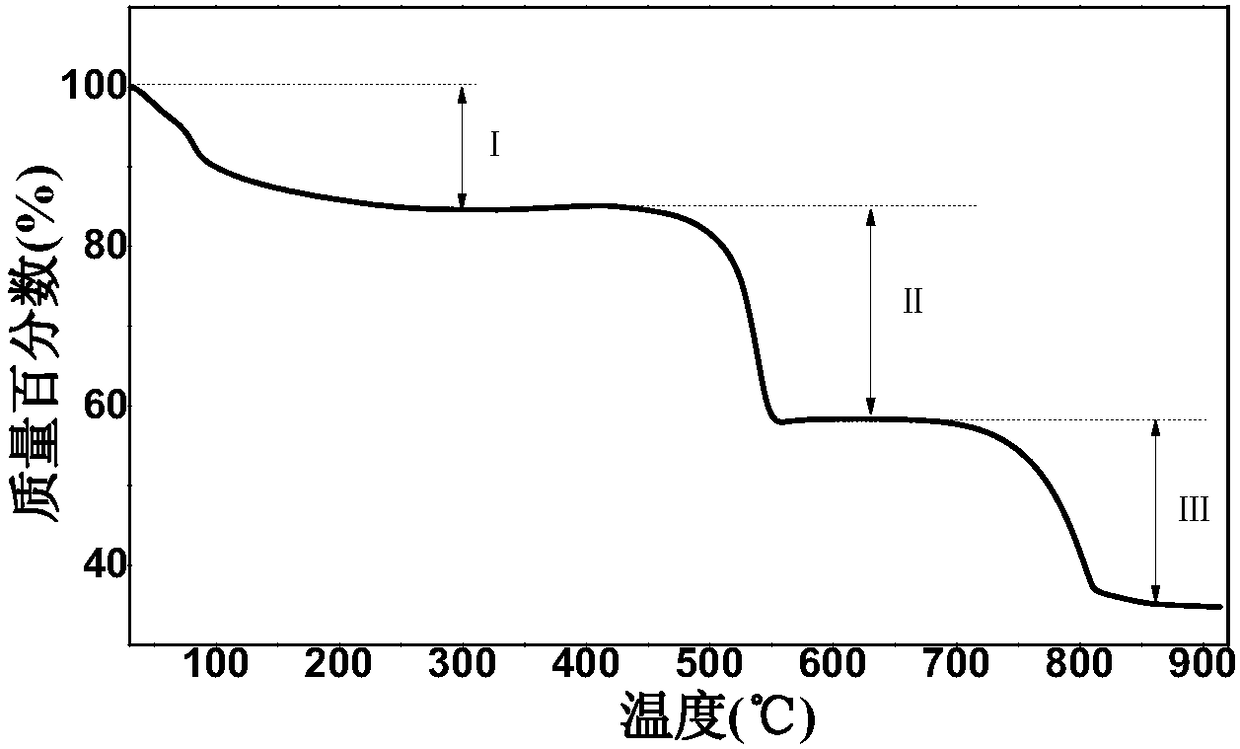

Sulfur and nitrogen codoping graphene loaded vulcanized cobalt and nickel catalytic material and preparation and application

A technology of cobalt-nickel sulfide and catalytic materials, which is applied in the field of electrochemical materials to achieve the effects of good conductivity, high current density and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Weigh 1mmol of cobalt acetate, 2mmol of nickel acetate and 9mmol of thiourea and dissolve them in 20mL of water and 30mL of tert-butanol solution, and stir at room temperature for 2 hours to obtain a uniformly mixed solution; slowly dropwise add 2mL of Ammonia and stirred for 2h to obtain a homogeneous solution.

[0040] (2) Add 40 mg of graphene oxide sol to the homogeneous solution in step (1), ultrasonically homogenize and stir for 1 h; transfer the solution obtained above to a 100 mL reactor, and perform a hydrothermal reaction at 180° C. for 12 h; The hydrothermal reaction product was subjected to centrifugal separation, washed with water and absolute ethanol three times respectively, then subjected to freezing treatment and dried in a vacuum freeze-drying oven for 24 hours to obtain a graphene-supported cobalt-nickel sulfide composite material.

[0041](3) Put the obtained graphene-supported cobalt-nickel sulfide composite material into a porcelain boat and pl...

Embodiment 2

[0046] (1) Weigh 1mmol of cobalt acetate, 2mmol of nickel acetate and 9mmol of thiourea and dissolve them in 20mL of water and 30mL of tert-butanol solution, and stir at room temperature for 3h to obtain a uniformly mixed solution; slowly dropwise add 2mL of Ammonia and stirred for 1h to obtain a homogeneous solution.

[0047] (2) Add 30.4mg of graphene oxide sol to the homogeneous solution in step (1), ultrasonically homogenize and stir for 1h; transfer the solution obtained above to a 100mL reactor, and perform a hydrothermal reaction at 150°C for 10h The hydrothermal reaction product is subjected to centrifugation, washed with water and absolute ethanol three times respectively, then subjected to freezing treatment and dried in a vacuum freeze-drying oven for 48 hours to obtain a graphene-supported cobalt-nickel sulfide composite material.

[0048] (3) Put the obtained graphene-supported cobalt-nickel sulfide composite material into a porcelain boat and place it in a tube f...

Embodiment 3

[0052] (1) Weigh 1mmol of cobalt acetate, 2mmol of nickel acetate and 9mmol of thiourea and dissolve them in 20mL of water and 30mL of tert-butanol solution, and stir at room temperature for 4h to obtain a uniformly mixed solution; slowly dropwise add 2mL of Ammonia and stirred for 1h to obtain a homogeneous solution.

[0053] (2) Add 304 mg of graphene oxide sol to the homogeneous solution in step (1), ultrasonically homogenize and stir for 2 h; transfer the solution obtained above to a 100 mL reactor, and perform a hydrothermal reaction at 200° C. for 15 h; The hydrothermal reaction product was subjected to centrifugation, washed with water and absolute ethanol three times respectively, then subjected to freezing treatment and dried in a vacuum freeze-drying oven for 36 hours to obtain a graphene-supported cobalt-nickel sulfide composite material.

[0054] (3) Put the obtained graphene-supported cobalt-nickel sulfide composite material into a porcelain boat and place it in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com