Copper and copper alloy surface cleaning liquid and preparation method thereof

A surface cleaning and copper alloy technology, applied in the field of metal surface treatment, can solve the problems of spots on the surface of copper parts, insignificant brightening effect, unstable hydrogen peroxide, etc., to achieve excellent cleaning effect, smooth surface and good stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1, the preparation of thickener

[0025] (1) Polymerization: Dissolve 2,4-toluene diisocyanate, N-methylmorpholine, ethylene glycol butyl ether and polyethylene glycol in acetone, heat and react to obtain a mixture solution. Among them, 2,4-toluene diisocyanate: N-methylmorpholine: ethylene glycol butyl ether: polyethylene glycol = 4:1:1:2, polymerization temperature 80°C;

[0026] (2) Capping: add acetone oxime to the mixture solution obtained in step S1, mix evenly, and heat to react to obtain the product. Among them, 2,4-toluene diisocyanate: acetone oxime = 2:1, and the end-capping temperature is 85°C.

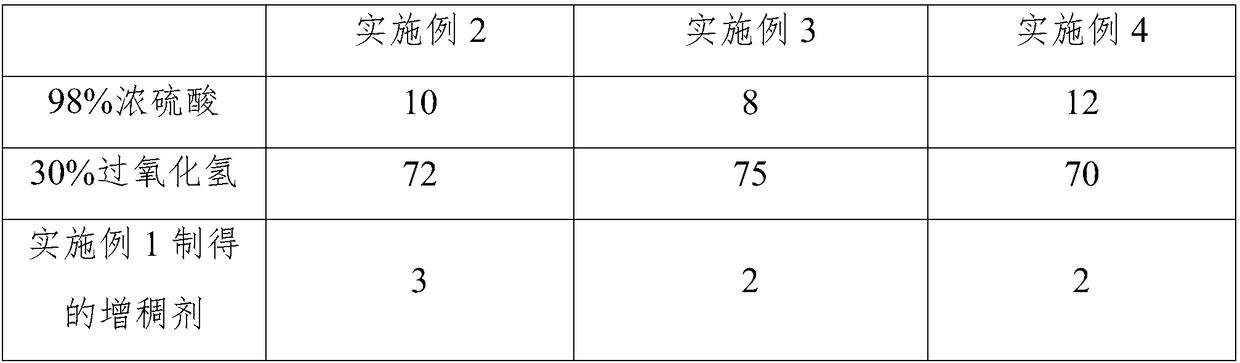

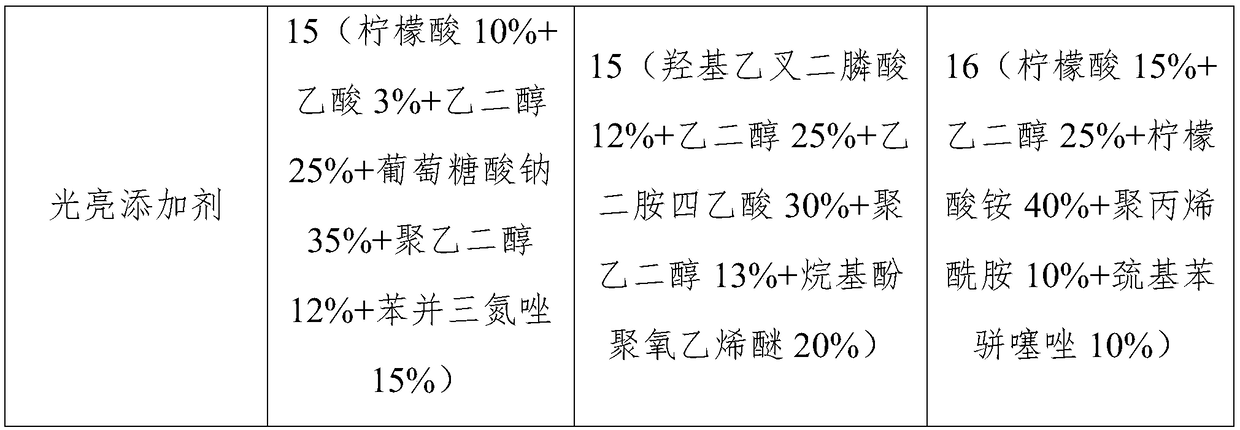

[0027] Copper and copper alloy surface cleaning liquid component and its proportioning ratio (%) described in the embodiment of the present invention 2-4

[0028]

[0029]

[0030] Preparation process: Accurately weigh each substance in proportion, add a certain amount of hydrogen peroxide into the bright pickling tank, then slowly add bright add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com