Pressure-sensitive adhesives and pressure-sensitive adhesive sheets

A pressure-sensitive adhesive sheet, pressure-sensitive adhesive layer technology, applied in the direction of adhesive type, pressure-sensitive film/sheet, ester copolymer adhesive, etc. Problems such as glare occur, and the effect of excellent step followability and excellent light diffusion can be achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0097] (2) Preparation of pressure-sensitive adhesive composition

[0098] The pressure-sensitive adhesive composition P can be prepared in the following manner: preparing the (meth)acrylate polymer (A), adding the obtained (meth)acrylate polymer (A), polyrotaxane compound (B ) and the crosslinking agent (C) are mixed, and additives are added as needed.

[0099] The (meth)acrylate polymer (A) can be produced by polymerizing a mixture of monomers constituting a polymer by a normal radical polymerization method. It is preferable to perform superposition|polymerization of a (meth)acrylate polymer (A) by the solution polymerization method using a polymerization initiator as needed. Examples of the polymerization solvent include ethyl acetate, n-butyl acetate, isobutyl acetate, toluene, acetone, hexane, methyl ethyl ketone, and the like, and two or more of them may be used in combination.

[0100] As a polymerization initiator, an azo compound, an organic peroxide, etc. are menti...

manufacture example

[0135] As another production example of the pressure-sensitive adhesive sheet 1, the above-mentioned coating solution of the pressure-sensitive adhesive composition P is applied to the release surface of one release sheet 12a, and heat-treated to make the pressure-sensitive adhesive composition P P is thermally cross-linked to form a coating layer, and the release sheet 12a with the coating layer is obtained. In addition, the above-mentioned coating solution of the pressure-sensitive adhesive composition P is applied to the release surface of the other release sheet 12b, and heat treatment is performed to thermally crosslink the pressure-sensitive adhesive composition P to form a coating layer. A release sheet 12b with a coating layer was obtained. Next, the peeling sheet 12a with a coating layer and the peeling sheet 12b with a coating layer are bonded together so that both coating layers may contact each other. When the curing period is required, the laminated coating layer...

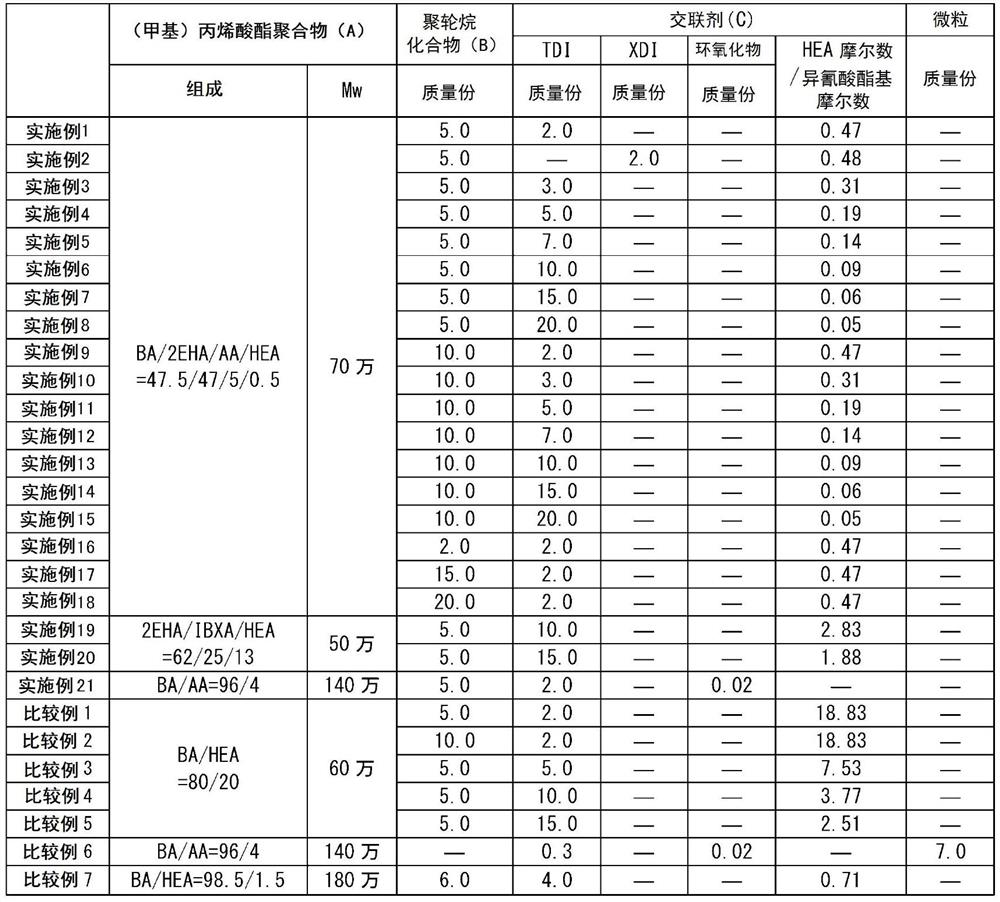

Embodiment 1

[0158] 1. Preparation of (meth)acrylate polymer

[0159] Copolymerize 47.5 parts by mass of n-butyl acrylate, 47 parts by mass of 2-ethylhexyl acrylate, 5 parts by mass of acrylic acid and 0.5 parts by mass of 2-hydroxyethyl acrylate by solution polymerization to prepare (meth)acrylic acid Ester polymer (A). As a result of measuring the molecular weight of this (meth)acrylate polymer (A) using the method mentioned later, it was 700,000 in weight average molecular weight (Mw).

[0160] 2. Preparation of pressure-sensitive adhesive composition

[0161] 100 parts by mass of the (meth)acrylate polymer (A) obtained in the above-mentioned step 1 (the value in terms of solid content, the same applies hereinafter), a polyrotaxane compound (B) (manufactured by Advanced Softmaterials Inc., product Name "SeRM Super Polymer SH 3407P", linear molecule: polyethylene glycol, cyclic molecule: α-cyclodextrin with hydroxypropyl and caprolactone chains, end-capping group: adamantyl, weight ave...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com