Nano oxidation aldehyde-free floor, production method thereof, nano oxidation aldehyde-eliminating liquid and eucalyptus-rosemary nano aldehyde-eliminating liquid

A nano-oxidation and production method technology, applied in the field of nano-oxidation aldehyde cleansing liquid and eucalyptus nano-aldehyde cleansing liquid, can solve the problems of limited formaldehyde release, increased technology and difficulty, etc., to achieve reduced formaldehyde release, strong Good permeability and net aldehyde effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

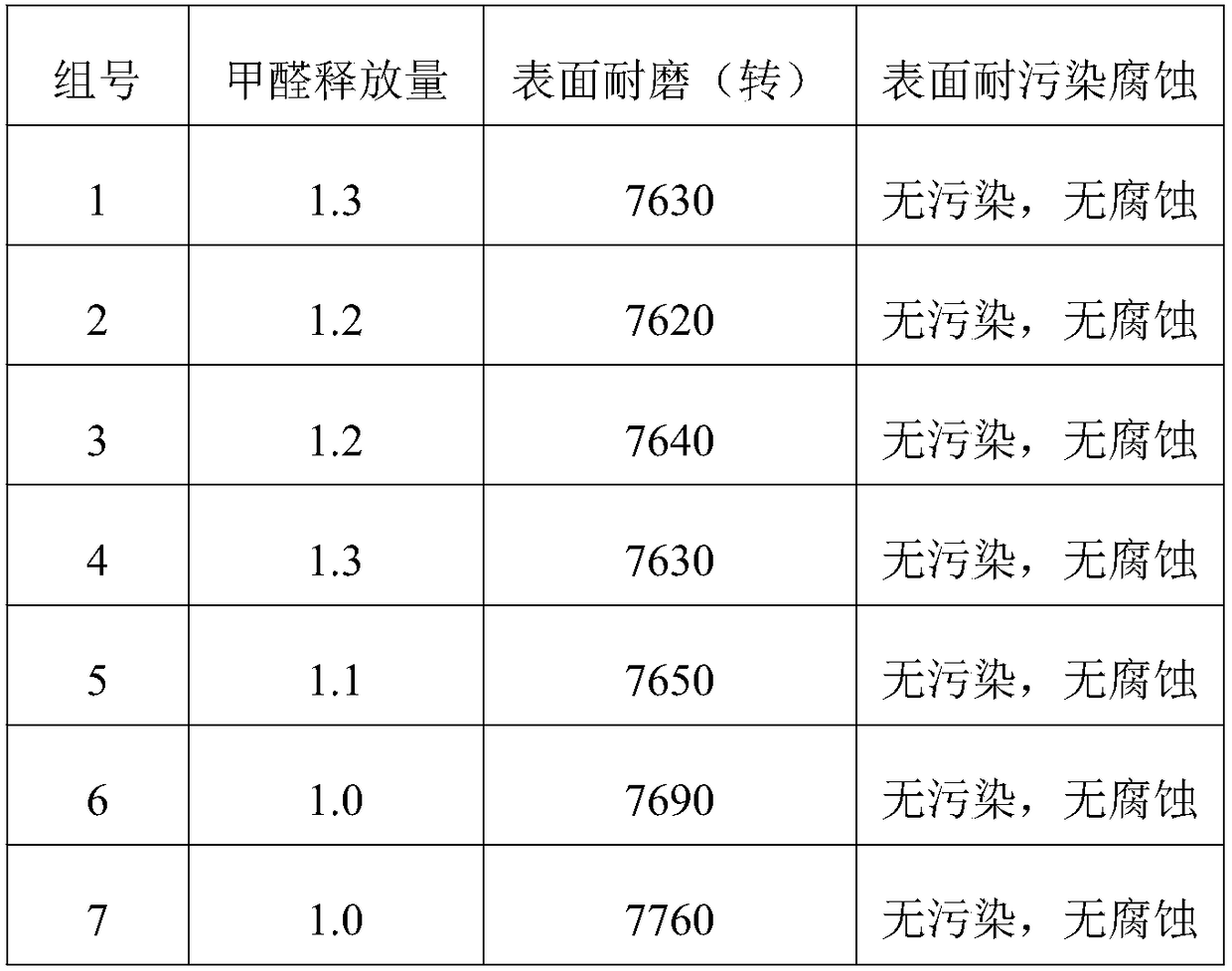

Examples

Embodiment 1

[0038] This embodiment provides a kind of eucalyptus nano aldehyde cleansing solution, which is prepared by mixing eucalyptus oil, rosemary oil and nano oxidized aldehyde cleansing solution according to the volume ratio of 0.8:0.8:1; wherein, the nano oxidized aldehyde cleansing solution The raw materials include, by weight, 0.5 parts of modified chitosan, 0.2 parts of penetrant, 1.5 parts of ethylene urea, 0.05 parts of nanometer zinc oxide, 0.05 part of nanometer silicon oxide and 65 parts of deionized water.

[0039] Present embodiment also provides a kind of production method of nano-oxidized aldehyde-cleaning floor, comprising: (1) spraying the above-mentioned eucalyptus nano-aldehyde-cleaning liquid in an amount of 12ml / m 2 Spray on the back of the fiberboard, then heat-press the balance paper on the back of the fiberboard at a temperature of 185°C and a pressure of 23Mpa for 9 seconds, then cool for 6 seconds; 2 Spray on the front of the fiberboard; then hot-press the d...

Embodiment 2

[0041] This embodiment provides a kind of eucalyptus nano aldehyde cleansing liquid, which is prepared by mixing eucalyptus oil, rosemary oil and nano oxidized aldehyde cleansing liquid according to the volume ratio of 1.5:1.5:1; wherein, the nano oxidized aldehyde cleansing liquid The raw materials include, by weight, 0.5 parts of modified chitosan, 0.2 parts of penetrant, 1.5 parts of ethylene urea, 0.05 parts of nanometer zinc oxide, 0.05 part of nanometer silicon oxide and 90 parts of deionized water.

[0042] Present embodiment also provides a kind of production method of nano-oxidized aldehyde-cleaning floor, comprising: (1) spraying the above-mentioned eucalyptus nano-aldehyde-cleaning liquid in an amount of 12ml / m 2 Spray on the back of the fiberboard, then heat-press the balance paper on the back of the fiberboard at a temperature of 185°C and a pressure of 23Mpa for 9 seconds, then cool for 6 seconds; 2 Spray on the front of the fiberboard; then hot-press the decorat...

Embodiment 3

[0044] This embodiment provides a kind of eucalyptus nano aldehyde cleansing liquid, which is prepared by mixing eucalyptus oil, rosemary oil and nano oxidized aldehyde cleansing liquid according to the volume ratio of 1:1:1; wherein, the nano oxidized aldehyde cleansing liquid The raw materials include, by weight, 0.5 parts of modified chitosan, 0.2 parts of penetrant, 1.5 parts of ethylene urea, 0.05 parts of nanometer zinc oxide, 0.05 part of nanometer silicon oxide and 90 parts of deionized water.

[0045] Present embodiment also provides a kind of production method of nano-oxidized aldehyde-cleaning floor, comprising: (1) spraying the above-mentioned eucalyptus nano-aldehyde-cleaning liquid in an amount of 12ml / m 2 Spray on the back of the fiberboard, then heat-press the balance paper on the back of the fiberboard at a temperature of 185°C and a pressure of 23Mpa for 9 seconds, then cool for 6 seconds; 2 Spray on the front of the fiberboard; then hot-press the decorative ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com