Nickel sulfide nanoparticle/nitrogen-doped fiber-based carbon aerogel composite material and preparation method therefor

A nanoparticle and carbon aerogel technology, applied in the field of nanomaterials, can solve the problems of limiting pseudocapacitive properties, easy agglomeration of nickel sulfide nanoparticles, poor recycling performance, etc. , the effect of excellent capacitance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

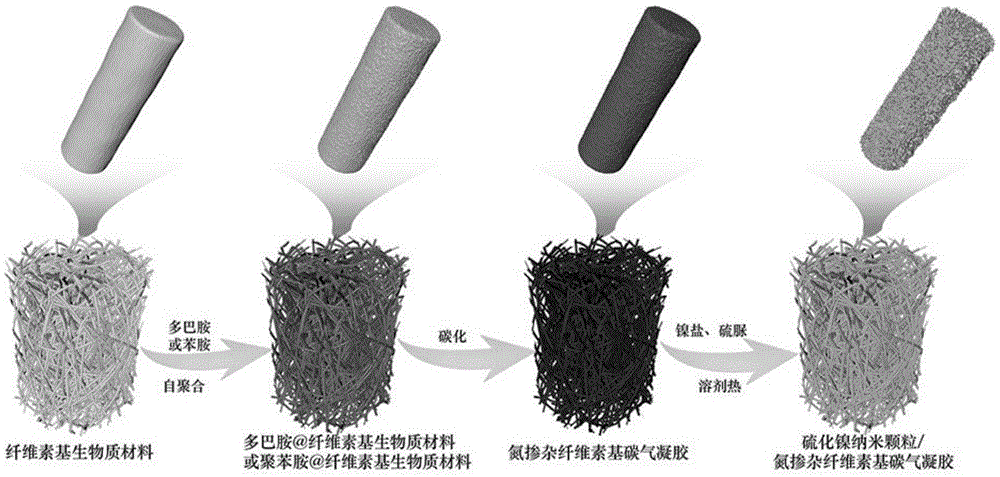

[0038] Example 1, This embodiment includes the following steps:

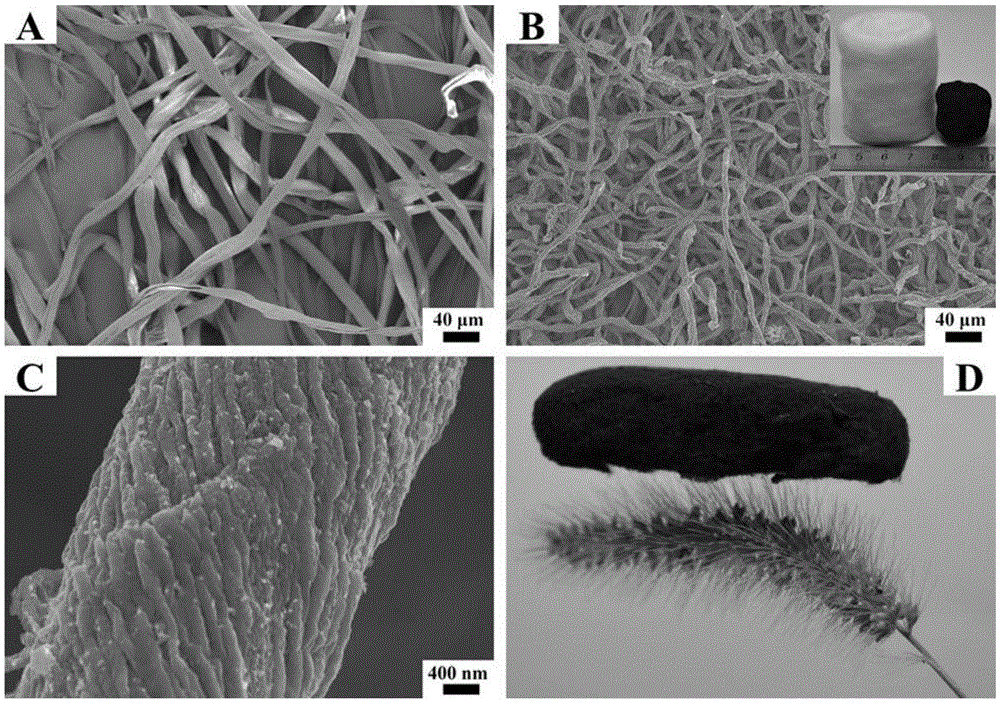

[0039] (1) Preparation of dopamine-coated fiber-based biomass materials. Dissolve 2.8g of tris(hydroxymethyl)aminomethane and 1.75g of tris(hydroxymethyl)aminomethane hydrochloride in 350mL of deionized water. After the dissolution is complete, add 350mg of dopamine monomer and stir to dissolve. Put 2 g of absorbent cotton into the above solution, place the dopamine solution containing absorbent cotton in a water bath at 60° C., and stir for 1 hour. After the reaction, wash the sample repeatedly with deionized water for 3-5 times, and dry it for later use;

[0040] (2) Take the dried polydopamine-coated absorbent cotton material in (1) and put it in a crucible, and carbonize it in a tube furnace at 800°C for 2 hours under the protection of nitrogen. The obtained nitrogen-doped cellulose-based carbon airgel is denoted as N DA -CFA;

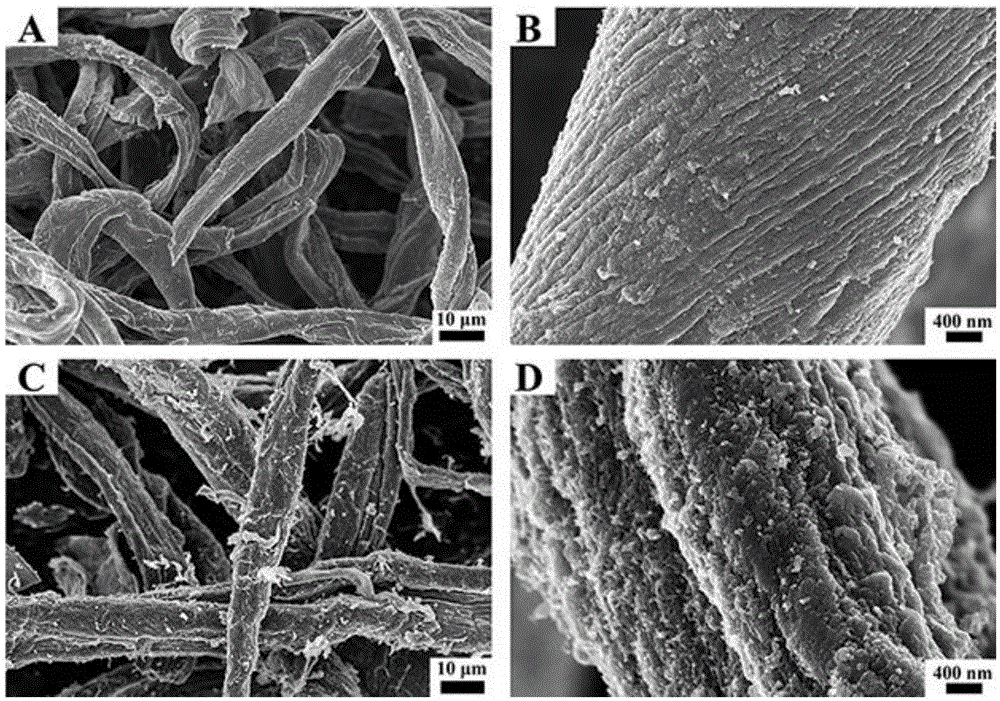

[0041] (3) Dissolve 2mmol of nickel acetate and 4mmol of thiourea in 30m...

Embodiment 2

[0042] Example 2 , the amount of nickel acetate and thiourea in Example 1 were changed to 4mmol and 8mmol respectively, the rest were the same as in Example 1, and the composite material finally obtained was recorded as NiS / N-CFA-4.

Embodiment 3

[0043] Example 3 , the amount of nickel acetate and thiourea in Example 1 was changed to 6mmol and 12mmol respectively, the rest were the same as in Example 1, and the composite material finally obtained was recorded as NiS / N-CFA-6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com