Method for preparing magnetic super-hydrophobic sponge materials

A super-hydrophobic sponge and magnetic technology, applied in separation methods, chemical instruments and methods, liquid separation, etc., to achieve excellent hydrophobic properties, economical and environmentally friendly preparation methods, and quick recovery effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

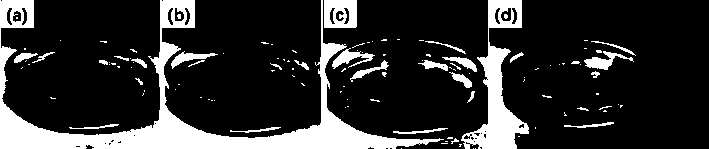

Image

Examples

Embodiment 1

[0026] A kind of preparation method of magnetic superhydrophobic sponge material, described method comprises the steps:

[0027] (1) Cleaning and pretreatment of the sponge: immerse the polyurethane sponge as a whole in deionized water, ultrasonically clean it at 40KHZ and 50W for 2 hours, take it out and dry it, then put it into an ultrasonic cleaning device equipped with acetone for ultrasonic cleaning for 2 hours, and the cleaning is completed Finally, take out the sponge and squeeze out the organic solvent to dry the sponge to get a spare sponge;

[0028] (2) Modified Fe 3 o 4 Solution preparation

[0029] 50 parts by mass of Fe 2 (SO 4 ) 3 9H 2 O and FeSO 4 ·7H 2 O mixture (Fe 2 (SO 4 ) 3 9H 2 O and FeSO 4 ·7H 2 The molar ratio of O is 2:1), added to the reactor containing 300 parts by mass of water and stirred evenly, and N was passed into the water containing the mixture 2 Gas, raise the temperature of the water bath to 60°C, slowly add 20 parts of ammoni...

Embodiment 2

[0036] A kind of preparation method of magnetic superhydrophobic sponge material, described method comprises the steps:

[0037] (1) Cleaning pretreatment of the sponge: immerse the polyether sponge as a whole in an ultrasonic cleaning device equipped with deionized water, ultrasonically clean it at 40KHZ and 100W for 2 hours, take it out and dry it, and then put it into an ultrasonic cleaning device filled with absolute ethanol. Ultrasonic cleaning in the cleaning device for 1.5 hours, take out the sponge, squeeze out the solvent and dry it for later use;

[0038] (2) Modified Fe 3 o 4 Solution preparation

[0039] 60 parts by mass of Fe 2 (SO 4 ) 3 9H2O and FeCl 2 4H 2 O (the molar ratio of which is 2:1), was added into the reaction kettle containing 350 parts by mass of water and stirred evenly, and N 2 Gas, raise the temperature of the water bath to 80°C, slowly add 30 parts of sodium hydroxide, then slowly add 15 parts of hexadecyltrichlorosilane within 1.5 hours,...

Embodiment 3

[0046] A kind of preparation method of magnetic superhydrophobic sponge material, described method comprises the steps:

[0047] (1) Cleaning and pretreatment of the sponge: immerse the melamine sponge as a whole in an ultrasonic cleaning device equipped with deionized water, ultrasonically clean it at 30KHZ and 200W for 1 hour, take it out and dry it, and then put it into an ultrasonic cleaner filled with isopropanol. Ultrasonic cleaning in the cleaning device for 1.5 hours, take out the sponge, squeeze out the solvent and dry it for later use;

[0048] (2) Modified Fe 3 o 4 Solution preparation

[0049] 80 parts by mass of FeCl 3 ·6H 2 O and FeSO 4 ·7H 2 O (the molar ratio of which is 2:1), was added to the reaction kettle containing 400 parts by mass of water and stirred evenly, and N 2 Gas, raise the temperature of the water bath to 70°C, slowly add 35 parts of potassium hydroxide, then slowly add 20 parts of octaalkyltrimethoxysilane within 1 hour, keep stirring fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water contact angle | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com