Preparation method of porous nano carbon material and application of porous nano carbon material in separation of propylene/propane

A technology of nano-carbon and propylene, which is applied in the direction of nano-carbon, separation method, dispersed particle separation, etc. It can solve the problems of cumbersome preparation steps, affect separation efficiency, reduce mass transfer rate, etc., and achieve the effect of broad industrial prospects and high-efficiency separation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

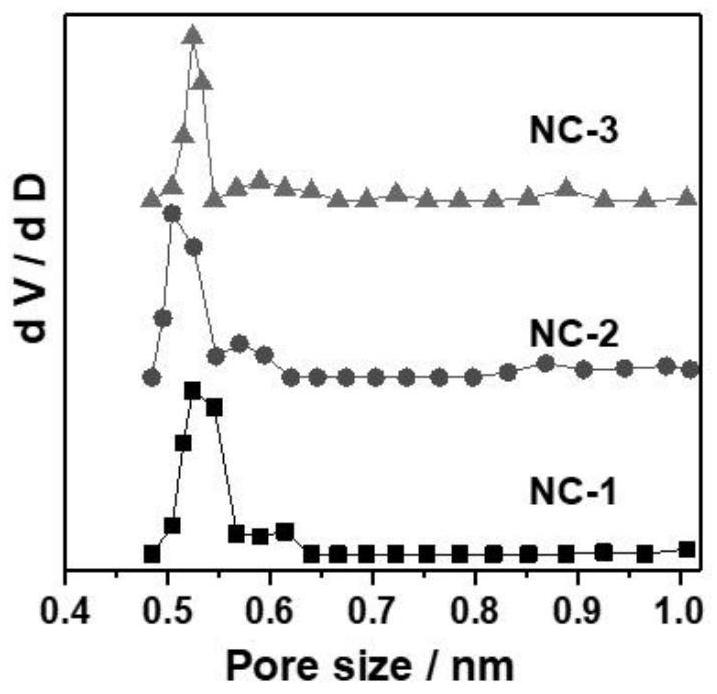

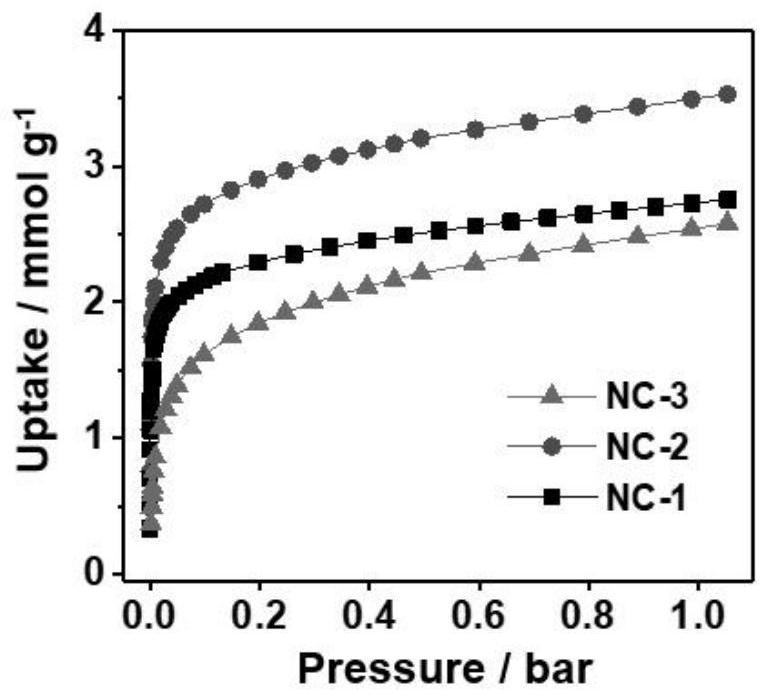

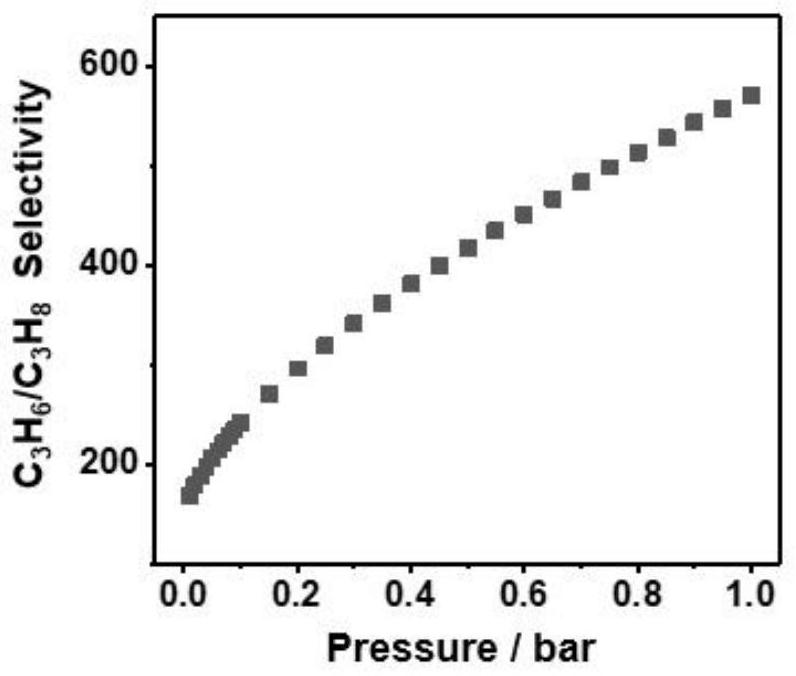

Embodiment 1

[0022] For the synthesis method of the phenalkamine polymer used in Example 1, refer to the preparation method of the document React.Funct.Polym., 2017, 121, 51, and the molecular weight of the phenalkamine polymer is 5900 g / mol. The phenalkamine polymer was placed in a tube furnace, purged for 2 h in a mixed atmosphere with an oxygen / argon volume ratio of 1:500 and a total flow rate of 300 mL / min, and then under an oxygen / argon mixed gas atmosphere from room temperature to 5 °C / min to 900 °C, constant temperature for 2 h, and cooled to room temperature to obtain porous nanocarbon NC-1. The pore size of ultra-micro pores is concentrated in 0.52-0.60nm, and the specific surface area is 560m 2 / g, micropore pore volume 0.28cm 3 / g. At 25°C and 1bar, C 3 H 6 and C 3 H 8 The static adsorption amounts were 2.75 mmol / g and 1.21 mmol / g, respectively, the IAST separation selectivity was 301, and the C 3 H 6 The interdiffusion constant is 8.6 × 10 -4 s -1 .

Embodiment 2

[0024] For the preparation method of the phenolic polymer used in Example 2, refer to the preparation method reported in the document "Chemical New Materials", 2015, 6, 158, and the molecular weight of the phenolic polymer is 26000 g / mol. The phenolic polymer was placed in a tube furnace, purged for 1 h in a mixed atmosphere with a hydrogen / argon volume ratio of 1:100 and a total flow rate of 200 mL / min, followed by a hydrogen / argon mixed gas atmosphere from room temperature to 8 ℃ / min was raised to 1000 ℃, constant temperature was 2 h, and cooled to room temperature to obtain porous nanocarbon NC-2. The pore size of ultra-micro pores is concentrated in 0.48-0.60nm, and the specific surface area is 669m 2 / g, micropore pore volume 0.28cm 3 / g. At 25°C and 1bar, C 3 H 6 and C 3 H 8 The static adsorption amounts were 3.53 mmol / g and 1.02 mmol / g, respectively, the IAST separation selectivity was 525, and the C 3 H 6 The interdiffusion constant is 6.6 × 10 -3 s -1 .

Embodiment 3

[0026]For the preparation method of the aldamine polymer used in Example 3, refer to the preparation method reported in the Journal of Molecular Structure, 2018, 1163, 22, and the molecular weight of the aldamine polymer is 12700 g / mol. The aldamine polymer was placed in a tube furnace, purged for 2 h under a mixed gas atmosphere with an oxygen / nitrogen volume ratio of 1:25 and a total flow rate of 100 mL / min, and then under an oxygen / nitrogen mixed gas atmosphere from room temperature to 2 ℃ / min was raised to 800 ℃, constant temperature was 0.3 h, and cooled to room temperature to obtain porous nanocarbon NC-3. The pore size of ultra-micro pores is concentrated in 0.52-0.60nm, and the specific surface area is 520m 2 / g, micropore pore volume 0.26cm 3 / g. At 25°C and 1bar, C 3 H 6 and C 3 H 8 The static adsorption amounts were 2.58 mmol / g and 1.11 mmol / g, respectively, the IAST separation selectivity was 296, and the C 3 H 6 The interdiffusion constant is 4.8 × 10 -4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Static adsorption capacity | aaaaa | aaaaa |

| Static adsorption capacity | aaaaa | aaaaa |

| Static adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com