A kind of 3D printing method of powder material

A 3D printing, powder material technology, applied in the field of additive manufacturing, can solve the problems of insufficient effective solid content, technical difficulty, high manufacturing cost, and large shrinkage rate of finished products, so as to achieve easy removal, easy maintenance, and reduced warpage. warp effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

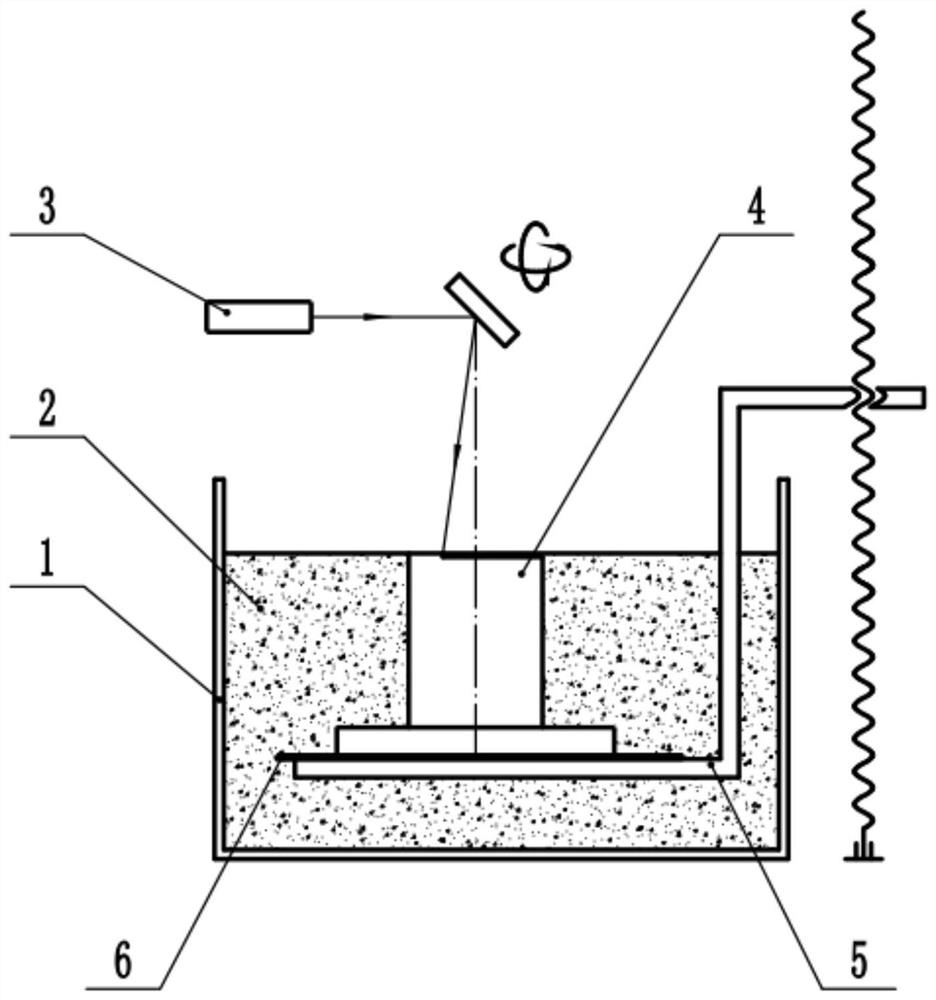

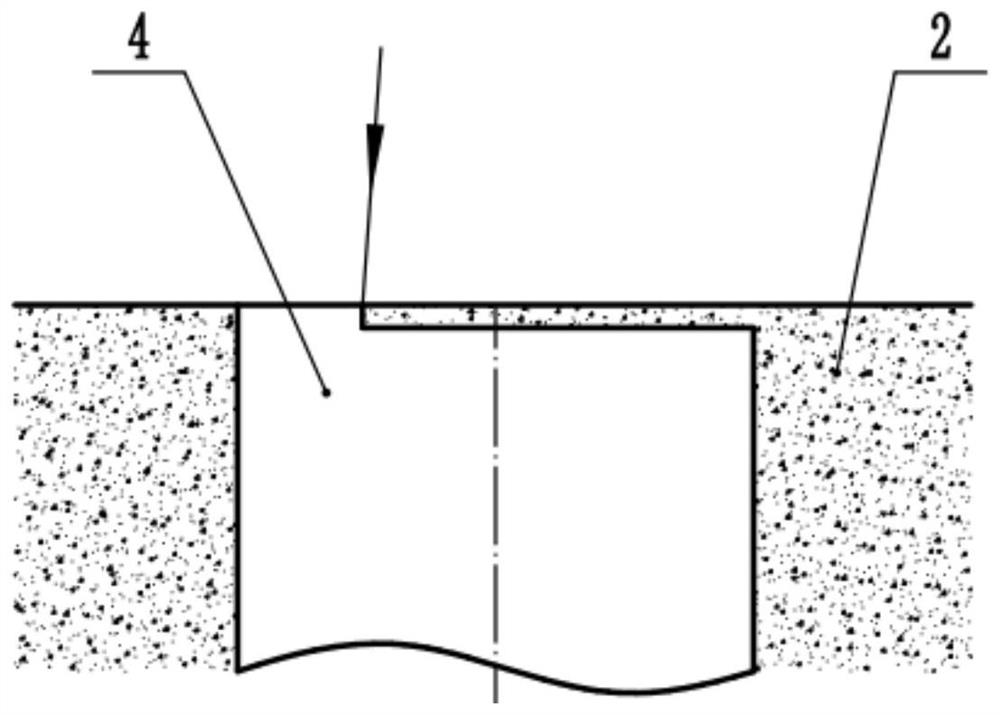

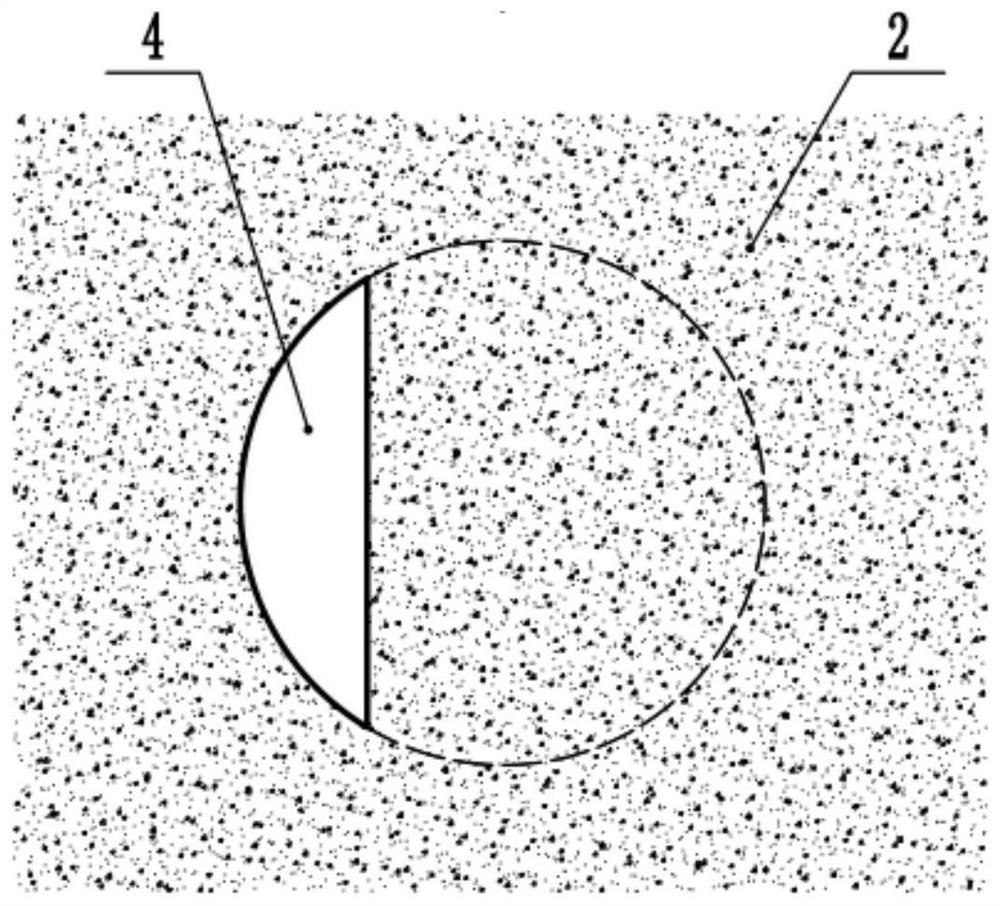

[0024] The device used in the 3D printing method of the powder material of the present invention is as figure 1 As shown, it is composed of a storage tank 1, a feed liquid 2, a laser 3, a lift table 5, and a molding substrate 6. The material liquid used for printing is stored in the material storage tank, the forming substrate 6 and the lifting table 5 are fixed for forming and lifting the workpiece 4, and the rotating lead screw can move up and down with the lifting table 5. The workpiece 4 is printed layer by layer from bottom to top, and the printed part is completely immersed in the material liquid 2 .

[0025] The method of the present invention is to add solid powder particles in a volatile solvent with better fluidity, use a dispersant to disperse them evenly, and add a solvent-soluble high polymer as a powder binder in the 3D printing process to prepare A 3D printing material liquid 2 with uniform solid phase dispersion and excellent fluidity. Before printing, store ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com