Gas adsorption equipment for supergravity movable adsorption bed

A technology for adsorbing gas and adsorption bed, which is applied in gas treatment, membrane technology, and separation of dispersed particles. It can solve the problems of low utilization rate of fixed bed adsorbent, long desorption time of fixed bed, unstable process operation, etc. Effect of desorption regeneration time, full utilization of industrial resources, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

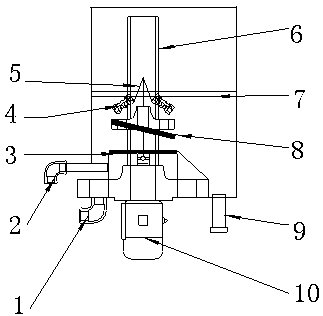

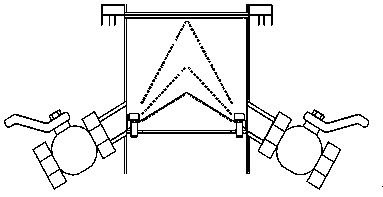

[0034] Example 1: For the toluene gas generated by the gas generator, activated carbon was used as the adsorbent, and the supergravity moving adsorption bed was used as the adsorption device to carry out the adsorption test. The design capacity of the whole device is 0-15m 3 / h, the diameter of the adsorption column is 50mm, and the rotation speed of the adsorption column can be adjusted at 0-900r / min. The concentration of toluene gas produced by the gas generator is maintained at 2000-3000ppm, and the intake air volume is 5m 3 / h, during the experiment, the adsorption performance of the three adsorption beds was studied by adjusting the rotation speed. Moving and rotating beds.

[0035] During the experiment, the loading amount of activated carbon was 300 g, and the adsorption time was 10 h. The results showed that the adsorption capacity of the fixed bed was 350 mg / g, the adsorption capacity of the moving bed was 450 mg / g, and the adsorption capacity of the rotating bed w...

Embodiment 2

[0036] Example 2: For the activated carbon saturated with adsorption, the supergravity moving adsorption bed was used for desorption, the desorption medium was nitrogen at 80 ° C, and the outlet concentration was maintained at 100 ppm, the desorption time required for the fixed bed was 200 min, and the moving bed The desorption time was 140min, and the desorption time required for rotation was 50min; at the same time, it was determined that the desorption time was 30min, the desorption rate of the fixed bed was 23%, the desorption rate of the moving bed was 36%, and the desorption rate of the rotating bed was 36%. The adsorption rate was 76%, indicating that the rotating bed has superior performance in the desorption of saturated activated carbon.

Embodiment 3

[0037] Example 3: For toluene gas with a concentration of 1000 ppm, a supergravity moving adsorption bed was used to carry out adsorption and desorption experiments. Adjust the rotation speed to 0r / min, the entire adsorption bed is in fixed bed mode, and the gas inlet is passed for 10m 3 / h of toluene gas, the activated carbon loading in the adsorption column is 500g, after 10h of adsorption, stop feeding toluene gas, change to 80% nitrogen, adjust the speed to 500r / min, at this time the adsorption bed is in the rotating bed mode, and the desorption is carried out. In the adsorption experiment, after 50 min of desorption, repeat the previous adsorption test of toluene gas, the adsorption amount reached 470 mg / g for 8 h, and the activated carbon still maintained a better adsorption effect. , to maintain a good adsorption and desorption effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com