Integrated lithium ion battery silicon/carbon negative electrode material and preparation method thereof

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of silicon materials losing electrical contact with conductive additives and current collectors, difficult to form a solid electrolyte interface, aggravated corrosion, and capacity fading , achieve excellent rate performance and cycle performance, avoid electrode cracking, and enhance charge transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment prepares the silicon carbon negative electrode material of lithium ion battery according to the following steps:

[0027] 1. Mix 0.12g of silicon powder (average particle size of 200nm), 0.09g of polyvinylidene fluoride and 0.02g of carbon nanotubes evenly, then add NMP solvent and stir for 16h to make a slurry;

[0028] 2. Evenly coat the prepared slurry on the copper foil with a thickness of 50 μm, dry it in an oven at 80°C, roll it, and then cut it into electrode sheets with a diameter of 14 mm;

[0029] 3. Under the protection of a nitrogen atmosphere, place the electrode sheet at 600°C for heat treatment for 2 hours, and cool to room temperature to obtain an integrated lithium-ion battery silicon / carbon negative electrode.

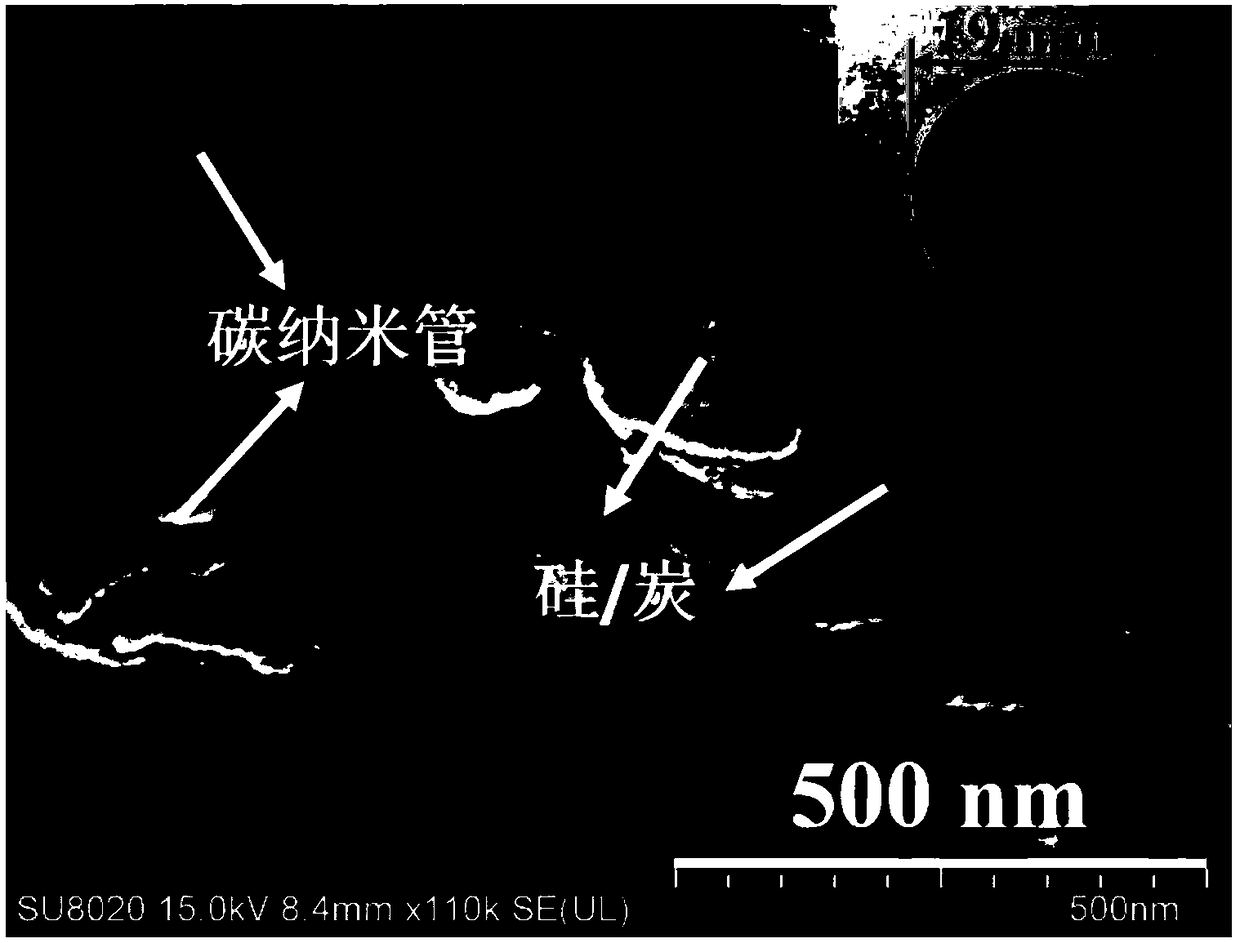

[0030] figure 1 It is the SEM photo of the silicon / carbon negative electrode of the integrated lithium-ion battery prepared in this example. It can be seen that the surface of the nano-silicon spheres is covered by pyrolytic ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com