Fracture-resisting face protection plate construction method

A construction method and technology for protective panels, applied in the direction of coastline protection, etc., can solve the problems of instability of concrete protective panels, cracks and fractures of concrete protective panels, etc., and achieve the effects of shortening construction period, good resistance to water impact, and firm structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

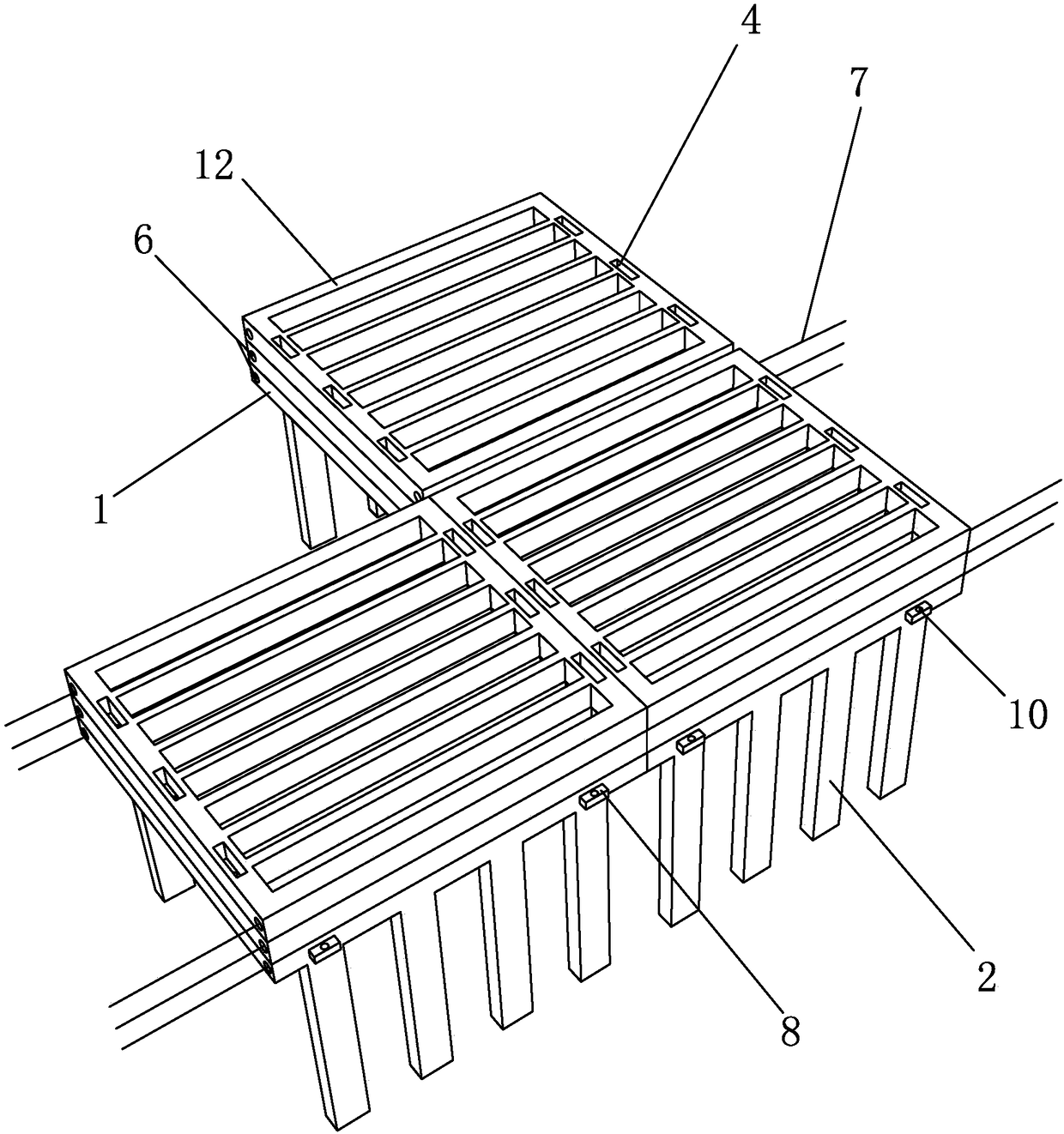

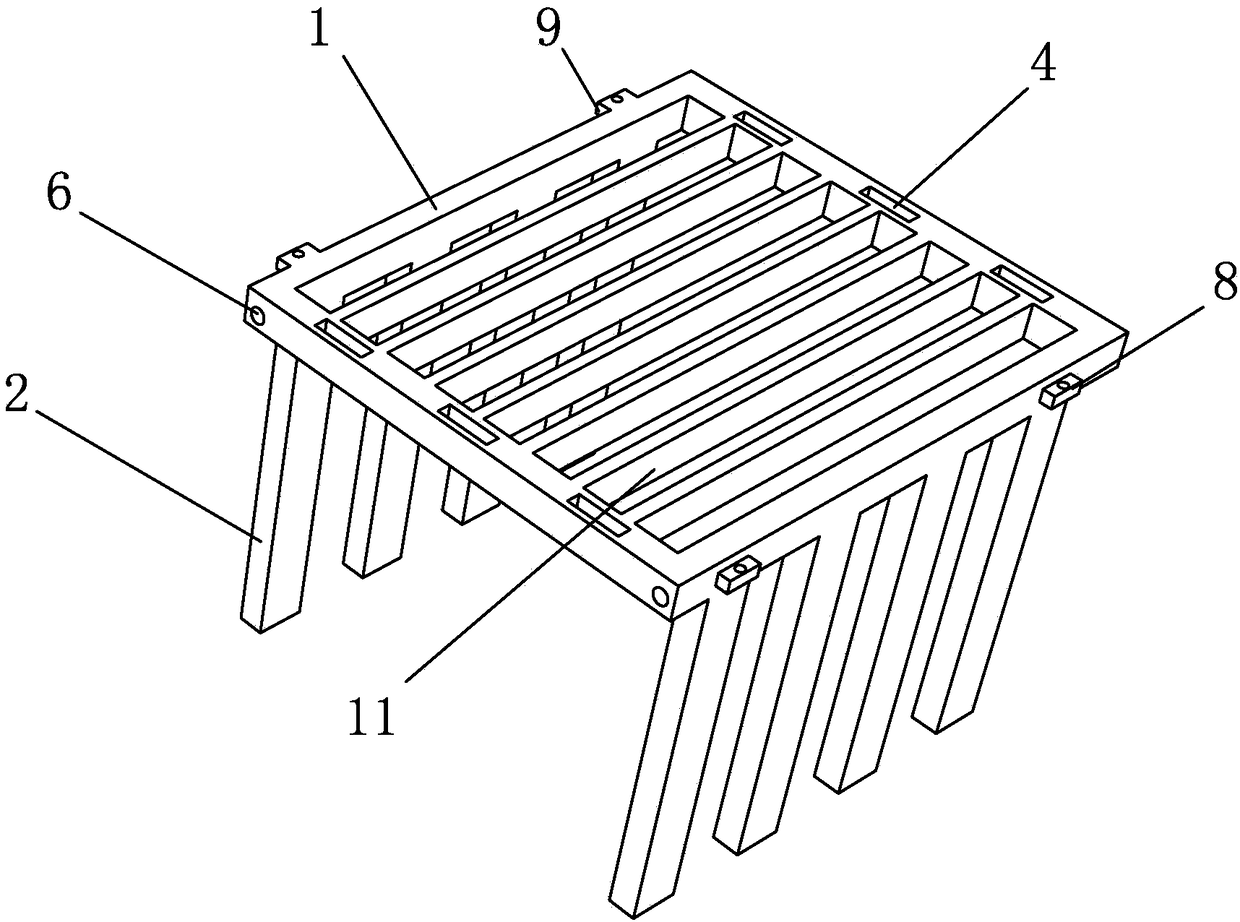

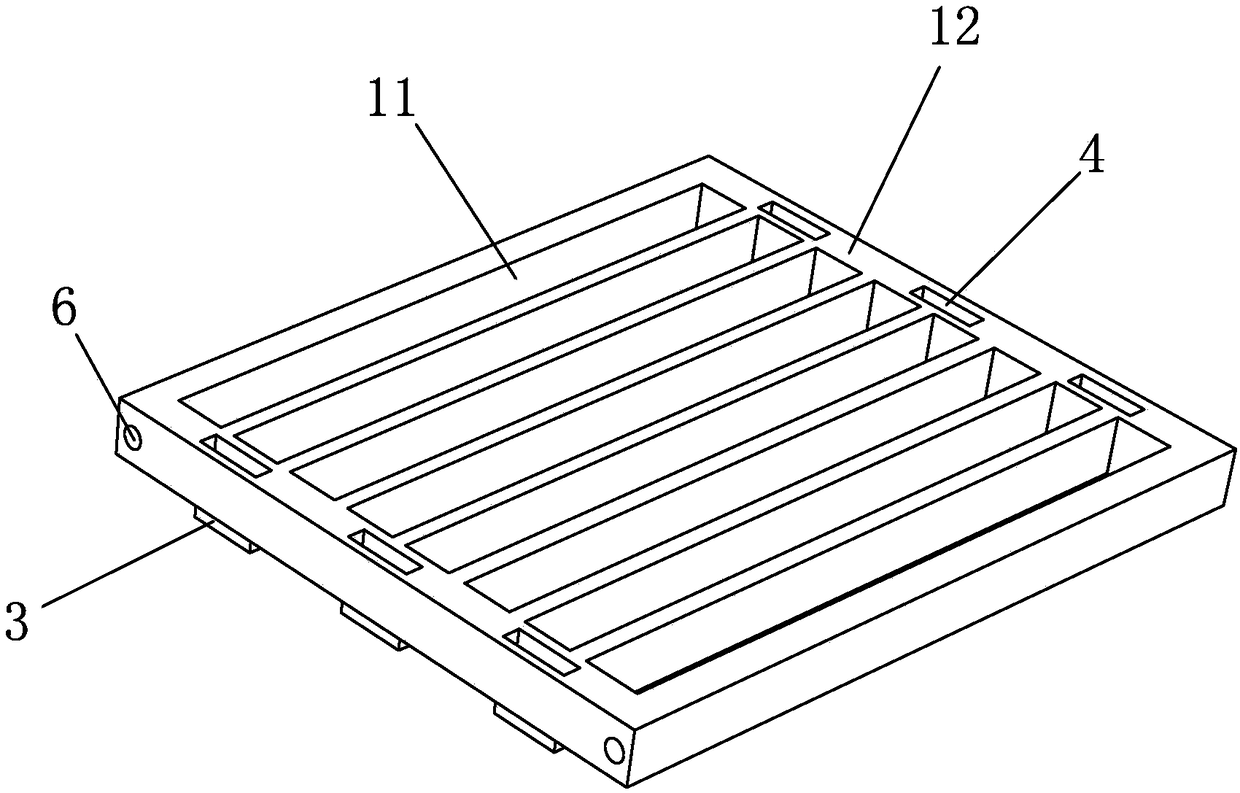

[0031] Such as Figure 1 to Figure 5 Shown, be a kind of anti-fragmentation protective panel construction method of the present invention, comprise the steps:

[0032] a. Foundation pit excavation

[0033] Survey the site, excavate the foundation of the construction embankment, excavate to the design elevation, then use the hook machine to level the construction embankment, and then carry out measurement and setting out;

[0034] b. Base treatment

[0035] Lay a layer of 15cm thick gravel cushion on the construction embankment, and use a hook machine to level and compact it, then lay a layer of geotextile membrane on the upper layer of the gravel cushion, and finally backfill soil above the geotextile membrane. The thickness of the backfill soil is controlled at 15-25cm, and compacted and flattened;

[0036] c. Laying of protective panels

[0037] (1) Laying of fixed steel plate 1 and raised steel plate 12

[0038] 1) First install the fixed steel plate 1, install the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com