Mold for fabricating starting gear in gear-reduction starter

A starting gear and starter technology, applied in the field of machinery, can solve the problems of poor mechanical performance of the starting gear, low utilization rate of raw materials, and low service life, and achieve the effects of stable performance, ingenious structural design, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

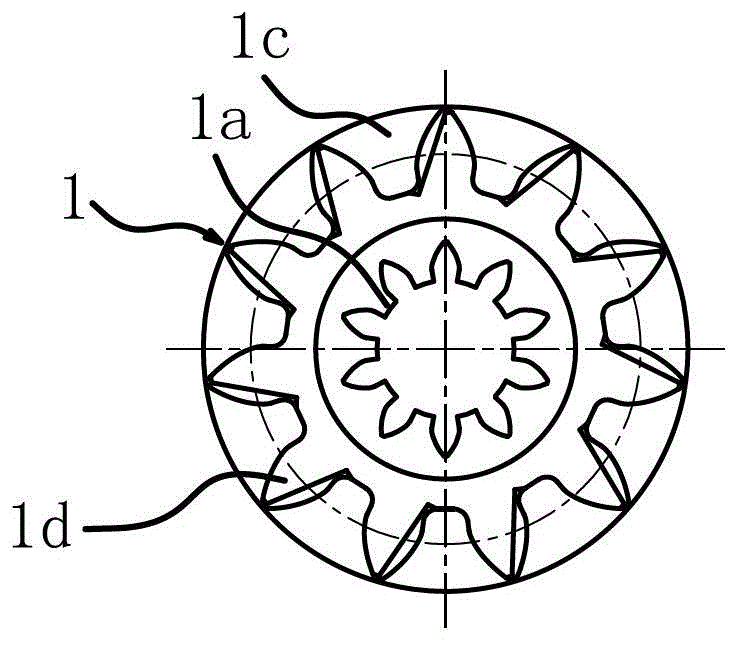

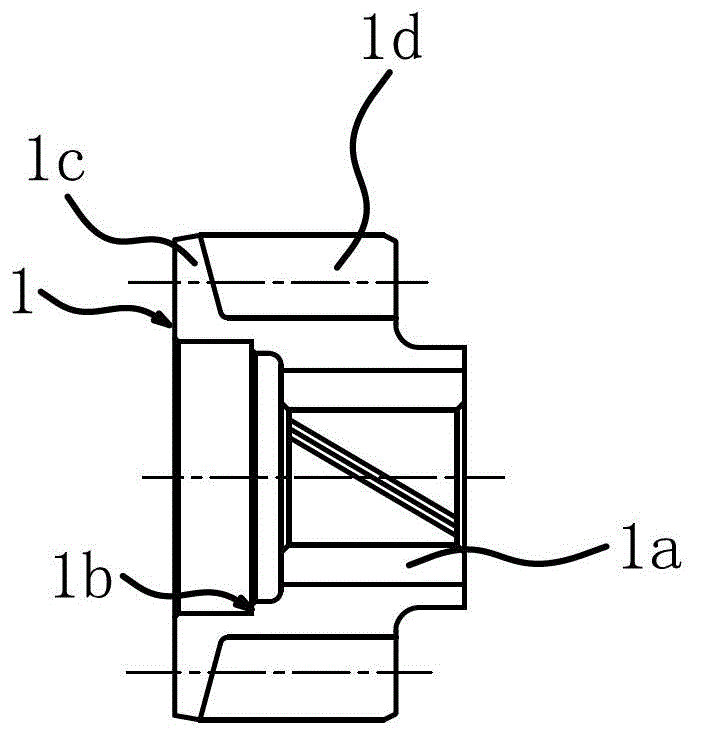

[0034] Such as figure 1 and figure 2 As shown, the starting gear in the deceleration starter includes a cylindrical body 1, the outer side of the body 1 has a convex shoulder 1c and several straight teeth 1d evenly distributed in the circumferential direction, and the inner side of the body 1 has a concave shoulder 1b and several teeth. Helical teeth 1a evenly distributed in the circumferential direction. The body 1 is made of alloy structural steel material, and the alloy structural steel is 20CrMo or 20Cr.

[0035] The manufacturing method of the starting gear in the deceleration starter mainly includes blanking, cold extrusion and surface treatment steps. Specifically, according to the materials used for making the starting gear, it is determined that the reduction of area should be controlled to be 81%-88% in the cold extrusion step, and the preferred value of the reduction of area is 84%-85%.

[0036]Select the bar stock that adopts the required material of making sta...

Embodiment 2

[0044] Such as Figure 6 As shown, the structure and principle of the present embodiment are basically the same as those of the first embodiment, except that the other end of the pressing rod 74 directly abuts against the pressing plate 72 . The pressing sleeve 75 is directly fixed on the mold base 71 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com