Storage battery grid with refined alloy grains and manufacturing method thereof

A grain refinement, battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as poor grid strength and corrosion resistance, and achieve the effects of improving corrosion resistance, delaying over-aging, and improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

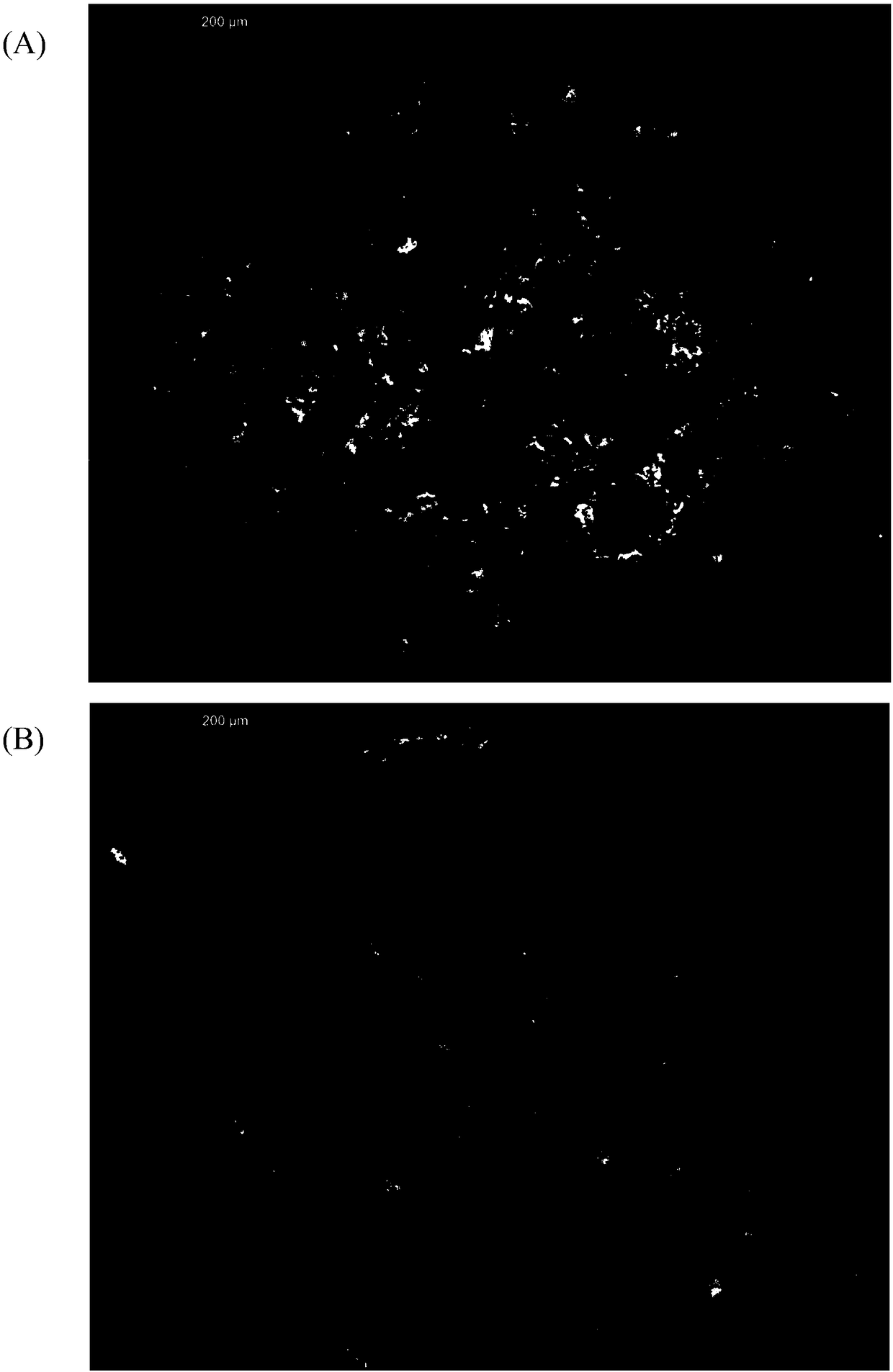

Image

Examples

Embodiment 1

[0045] 1. Battery grid formula: tin Sn 1.2%; silver Ag 0.01%; strontium Sr 0.08%; lithium Li 0.03%; calcium Ca 0.03%; aluminum Al 0.03%; lanthanum La 0.03%; cerium Ce 0.03%; Antimony 0.05%, the balance is lead.

[0046] 2. Preparation method of battery grid

[0047] 2.1 Preparation of grid alloy ingot

[0048] (1) Add one-tenth of the lead in the formula quantity to the batching pot and heat it to 1000°C, add the formula quantity La and Ce, keep the temperature, then stir at 300r / min for 40 minutes, and then cool down naturally;

[0049] (2) Add Sr when the temperature of the alloy liquid drops to 800°C, and continue to stir for 20 minutes, and then continue to cool down;

[0050] (3) The temperature of the alloy liquid drops to 600°C, put out the mixer, then wrap the Ca and Al with tin foil in the formula amount, put it in a device similar to a bell jar and perforate it, and press the device on the bottom of the lower layer of the batching pot with an iron rod , after ther...

Embodiment 2

[0079] 1. Battery grid formula: tin Sn 0.6%; silver Ag 0.008%; strontium Sr 0.06%; lithium Li 0.04%; calcium Ca 0.05%; aluminum Al 0.04%; lanthanum La 0.05%; cerium Ce 0.02%; antimony Indium 0.03%, the balance is lead.

[0080] 2. Preparation method of battery grid

[0081] 2.1 Preparation of grid alloy ingot

[0082] (1) Add one-tenth of the lead in the formulation amount to the batching pot and heat it to 1050°C, add the formulation amount La and Ce, keep the temperature, then stir at 200r / min for 20 minutes, and then cool down naturally;

[0083] (2) Add Sr when the temperature of the alloy liquid drops to 850°C, and continue to stir for 20 minutes, and then continue to cool down;

[0084] (3) The temperature of the alloy liquid drops to 650°C, put out the mixer, then wrap the Ca and Al with tin foil in the formula amount, put it in a bell jar and perforate the appliance, and press the appliance on the bottom of the lower layer of the batching pot with an iron rod , afte...

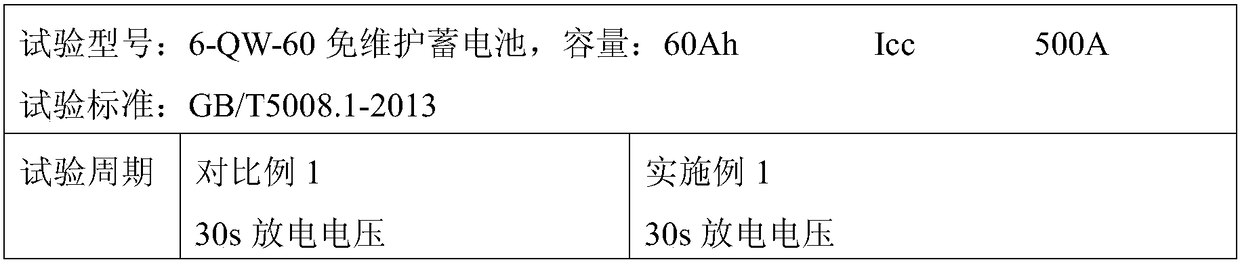

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com