Luminous rotationally molded plastic hull and preparation method thereof

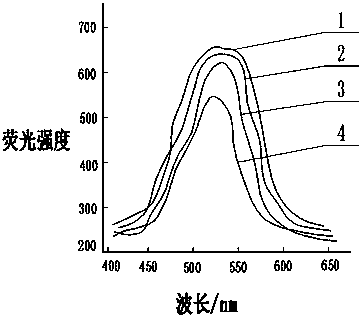

A hull, rotational molding technology, applied in the field of chemical materials, can solve the problems of aesthetics, poor playability, poor night visibility, surface coating damage, etc., to avoid fluorescence quenching, enhance aesthetics, and good luminous performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

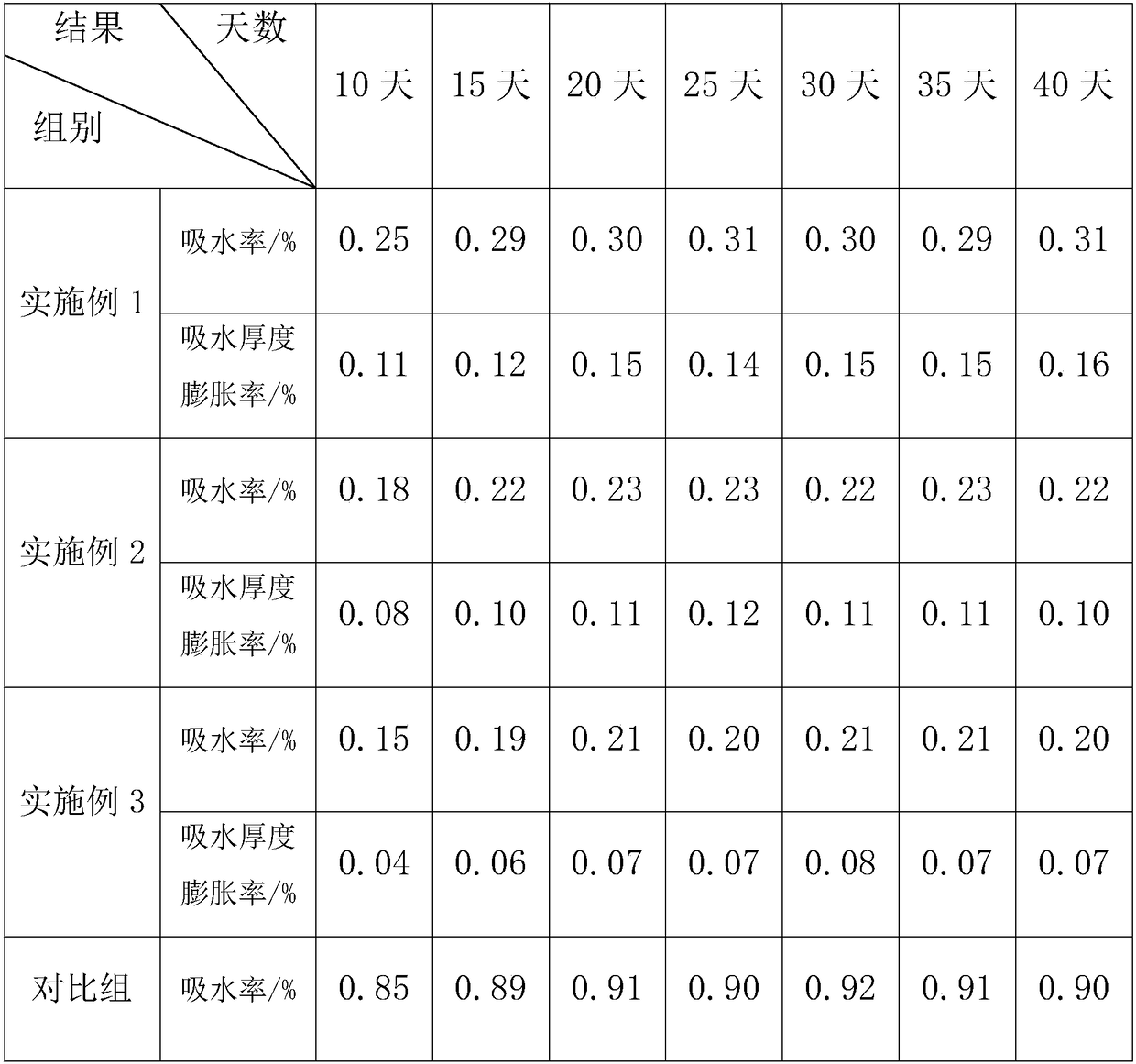

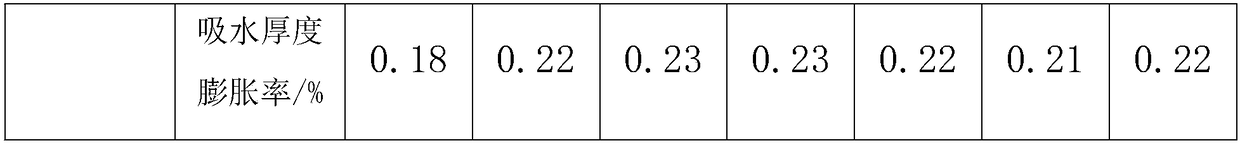

Embodiment 1

[0030] The luminous rotomolded hull of this embodiment, the parts by weight of the various substances added are: 10 parts of rare earth long-lasting phosphor, 80 parts of high molecular polymer, 8 parts of auxiliary agent, 20 parts of acetone, 15 parts of benzene, thiocyanic acid 15 parts of iron, 9 parts of tetramethylammonium chloride, 6 parts of hydroquinone, 15 parts of triethylamine, 40 parts of benzoic acid, 120 parts of acetone.

[0031] The manufacturing method of the luminous rotomolded hull of this embodiment includes the following steps:

[0032] (1) Drying: dry the rare earth long-lasting phosphor and polymer for 7 hours under the same conditions;

[0033] (2) React acetone and benzene at 30°C for 40 minutes, then add high molecular polymer, stir evenly and heat to 100°C;

[0034] (3) Add rare earth long afterglow fluorescent powder to the reaction system of step (2), carry out magnetic stirring for 3 hours, then add ferric thiocyanate, tetramethylammonium chlorid...

Embodiment 2

[0039] The parts by weight of the luminous rotomolded hull of this embodiment are: 13 parts of rare earth long-lasting phosphor, 75 parts of high molecular polymer, 5 parts of auxiliary agent, 25 parts of acetone, 20 parts of benzene, thiocyanic acid 17 parts of iron, 12 parts of tetramethylammonium chloride, 9 parts of hydroquinone, 20 parts of triethylamine, 48 parts of benzoic acid, and 125 parts of acetone.

[0040] The manufacturing method of the luminous rotomolded hull of this embodiment includes the following steps:

[0041] (1) Drying: Dry the rare earth long-lasting phosphor and polymer for 7.5 hours under the same conditions;

[0042] (2) React acetone and benzene at 30°C for 40 minutes, then add high molecular polymer, stir evenly and heat to 110°C;

[0043] (3) Add rare earth long afterglow phosphor to the reaction system of step (2), carry out magnetic stirring for 4 hours, then add ferric thiocyanate, tetramethylammonium chloride and hydroquinone therein, stir ...

Embodiment 3

[0048]The parts by weight of the luminous rotomolded hull of this embodiment are: 15 parts of rare earth long-lasting phosphor, 70 parts of high molecular polymer, 3 parts of auxiliary agent, 30 parts of acetone, 17 parts of benzene, thiocyanic acid 20 parts of iron, 14 parts of tetramethylammonium chloride, 7 parts of hydroquinone, 25 parts of triethylamine, 43 parts of benzoic acid, and 130 parts of acetone.

[0049] The manufacturing method of the luminous rotomolded hull of this embodiment includes the following steps:

[0050] (1) Drying: dry the rare earth long-lasting phosphor and high molecular polymer under the same conditions for 8 hours;

[0051] (2) React acetone and benzene at 30°C for 40 minutes, then add high molecular polymer, stir evenly and heat to 120°C;

[0052] (3) Add rare earth long afterglow phosphor to the reaction system of step (2), carry out magnetic stirring for 5 hours, then add ferric thiocyanate, tetramethylammonium chloride and hydroquinone th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com