Flame-retardant ABS material for weather-resistant washing-resisting closestool and preparation method thereof

A technology of ABS material and ABS resin, which is applied in the field of flame-retardant ABS material and its preparation, can solve the problems of long service life, aging, yellowing, etc., and achieve the effect of high fluidity, small shrinkage rate and improved fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

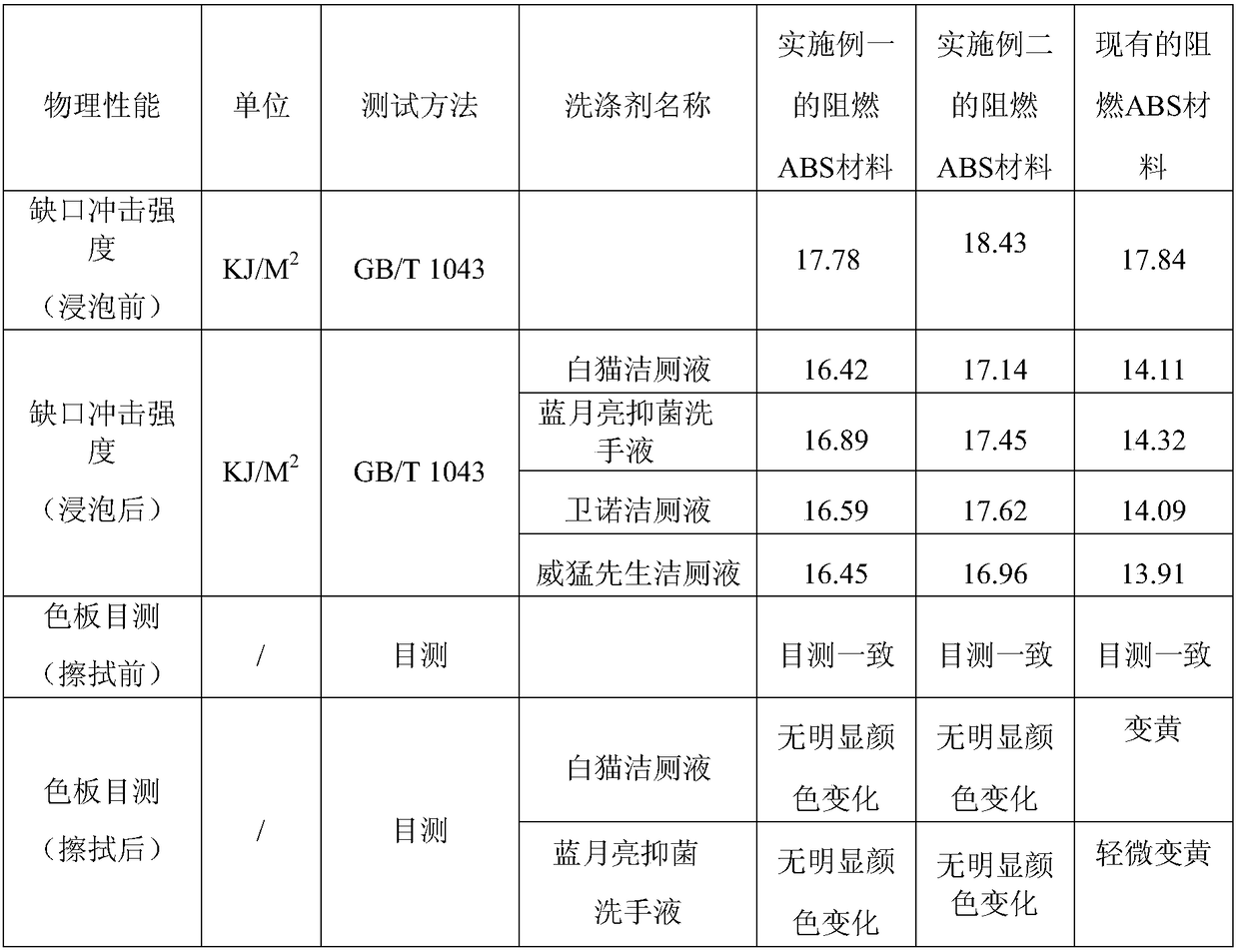

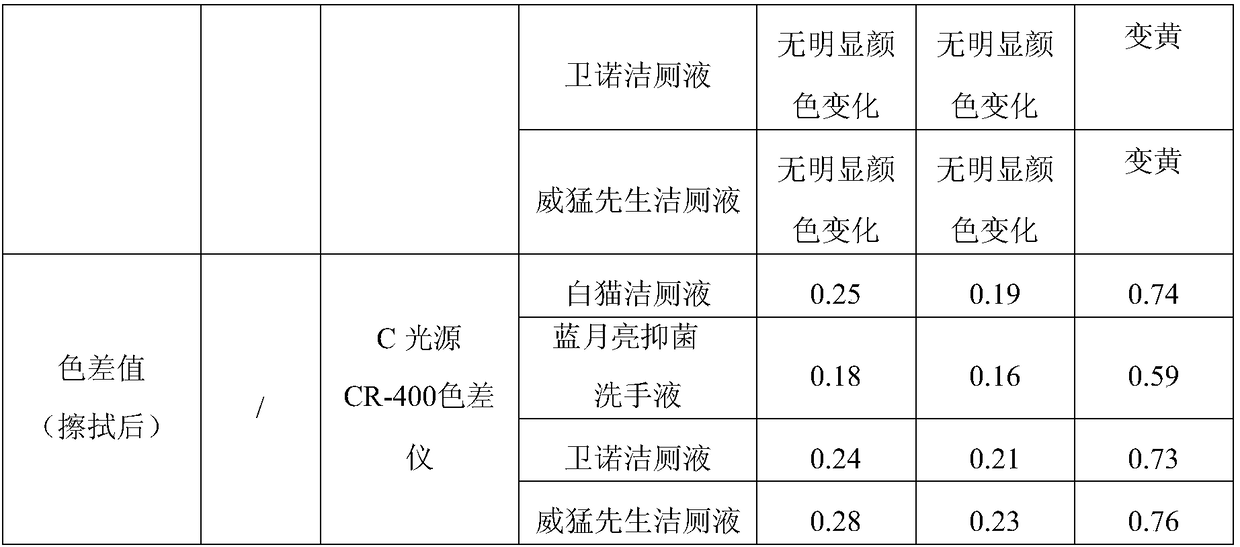

Examples

no. 1 example

[0020] The flame-retardant ABS material used for the weather-resistant and washing-resistant toilet includes 59-61% of ABS resin, 4-6% of AS resin, 5-7.5% of toughening agent, 17.6-17.8% of flame retardant, and precipitated barium sulfate. 5-6%, lubricating dispersant 0.5%, anti-dripping agent 0.2%, antioxidant 0.4%, light stabilizer 0.3%, ultraviolet absorber 0.3% and titanium dioxide 3-4%.

[0021] Among them, the ABS resin is ABS AG12A1 or ABS 747S; the AS resin is AS2200 or AS80HF; the flame retardant includes bromotriazine 14% and antimony trioxide 3.6-3.8% by weight percentage; the toughening agent is ABS HR-181 high Rubber powder, produced by Kumho Corporation of South Korea; the content of barium sulfate in precipitated barium sulfate is 98.1%, supplied by Qingyuan Laike New Material Co., Ltd., the brand is MB102; the content of effective substances in bromotriazine is 98.5%; trioxide The active substance content in diantimony is 99.8%, whiteness ≥ 95%, and particle si...

no. 2 example

[0028] The flame retardant ABS material used for this weather-resistant and washing-resistant toilet is different from the first embodiment in that it includes ABS 747S 59.7%, AS80HF 6%, toughening agent 5%, bromotriazine 14%, trioxide 3.6% antimony, 6% precipitated barium sulfate, 0.5% lubricating dispersant, 0.2% anti-dripping agent, 0.4% antioxidant, 0.3% light stabilizer, 0.3% ultraviolet absorber and 4% titanium dioxide.

[0029] Other parts not described are the same as those of the first embodiment, and will not be analyzed and described here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com