Edible mushroom culture medium and preparation method thereof

A technology of edible fungi and culture medium, which is applied in the field of edible fungus culture medium and its preparation, can solve the problems of waste recycling affecting the culture medium, poor air permeability of the culture medium, and difficult biodegradation, so as to reduce water replenishment procedures and shorten the growth cycle , Nutrient-rich effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

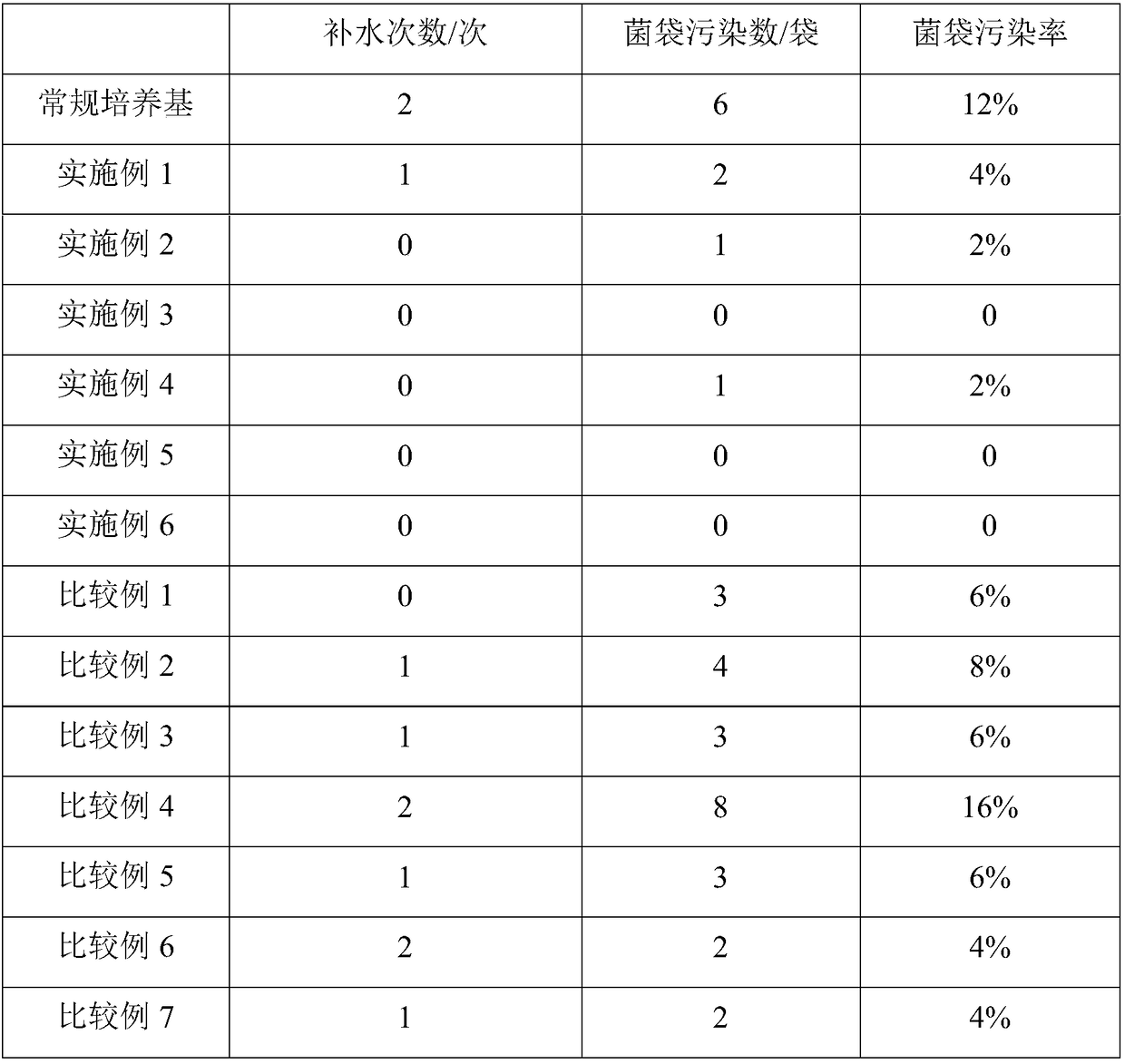

Examples

Embodiment 1

[0042] An edible fungus culture medium, comprising the following components by mass fraction: 15 parts of edible fungus residues, 8 parts of edible fungus roots, 30 parts of tea seed shells, 15 parts of sunflower seed meal, 6 parts of mink manure, and edible fungus water-retaining agent 0.8 parts, 23 parts of straw particles, 2 parts of compound regulator, 1.5 parts of lime.

[0043] The preparation steps of the edible fungus culture medium are as follows:

[0044] (1) After cleaning the edible mushroom root, send it to a beater, add an appropriate amount of water for beating, then add cellulase and protease to the edible mushroom root slurry for enzymatic hydrolysis, and heat inactivation after the enzymatic hydrolysis to obtain edible fungi Mushroom root enzymolysis slurry;

[0045] (2) adding acetic acid aqueous solution in mink excrement, wherein the mass fraction of acetic acid aqueous solution is 3%, the mass ratio of mink excrement and acetic acid aqueous solution is 1...

Embodiment 2

[0057] An edible fungus culture medium, comprising the following components in mass fractions: 25 parts of edible fungus residue, 6 parts of edible fungus roots, 15 parts of tea seed shells, 25 parts of sunflower seed meal, 8 parts of mink manure, and edible fungus water-retaining agent 2 parts, 15 parts of straw particles, 3 parts of compound regulator, 1 part of lime.

[0058] The preparation steps of the edible fungus culture medium are as follows:

[0059] (1) After cleaning the edible mushroom root, send it to a beater, add an appropriate amount of water for beating, then add cellulase and protease to the edible mushroom root slurry for enzymatic hydrolysis, and heat inactivation after the enzymatic hydrolysis to obtain edible fungi Mushroom root enzymolysis slurry;

[0060] (2) adding acetic acid aqueous solution in mink excrement, wherein, the mass fraction of acetic acid aqueous solution is 5%, the mass ratio of mink excrement and acetic acid aqueous solution is 1:0.8...

Embodiment 3

[0072] An edible fungus culture medium, comprising the following components in mass fractions: 20 parts of edible fungus residues, 7 parts of edible fungus roots, 23 parts of tea seed shells, 20 parts of sunflower seed meal, 7 parts of mink manure, and edible fungus water-retaining agent 1.5 parts, 30 parts of straw particles, 2.5 parts of compound regulator, 0.5 part of lime.

[0073] The preparation steps of the edible fungus culture medium are as follows:

[0074] (1) After cleaning the edible mushroom root, send it to a beater, add an appropriate amount of water for beating, then add cellulase and protease to the edible mushroom root slurry for enzymatic hydrolysis, and heat inactivation after the enzymatic hydrolysis to obtain edible fungi Mushroom root enzymolysis slurry;

[0075] (2) adding acetic acid aqueous solution in mink manure, wherein, the mass ratio of mink manure and acetic acid aqueous solution is 1:1.1, the mass fraction of acetic acid aqueous solution is 4%,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grinding particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com