Crude oil bin cleaning system and method for FPSO (floating production storage and offloading) unit in offshore drilling platform

A technology of drilling platform and cleaning method, which is applied to the cleaning equipment of ship liquid tanks, oil tank ships, special-purpose ships, etc., can solve the problems of consuming a lot of manpower and material resources, time and energy, and low cleaning efficiency, and achieve cleaning Good effect, high efficiency, and thorough cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

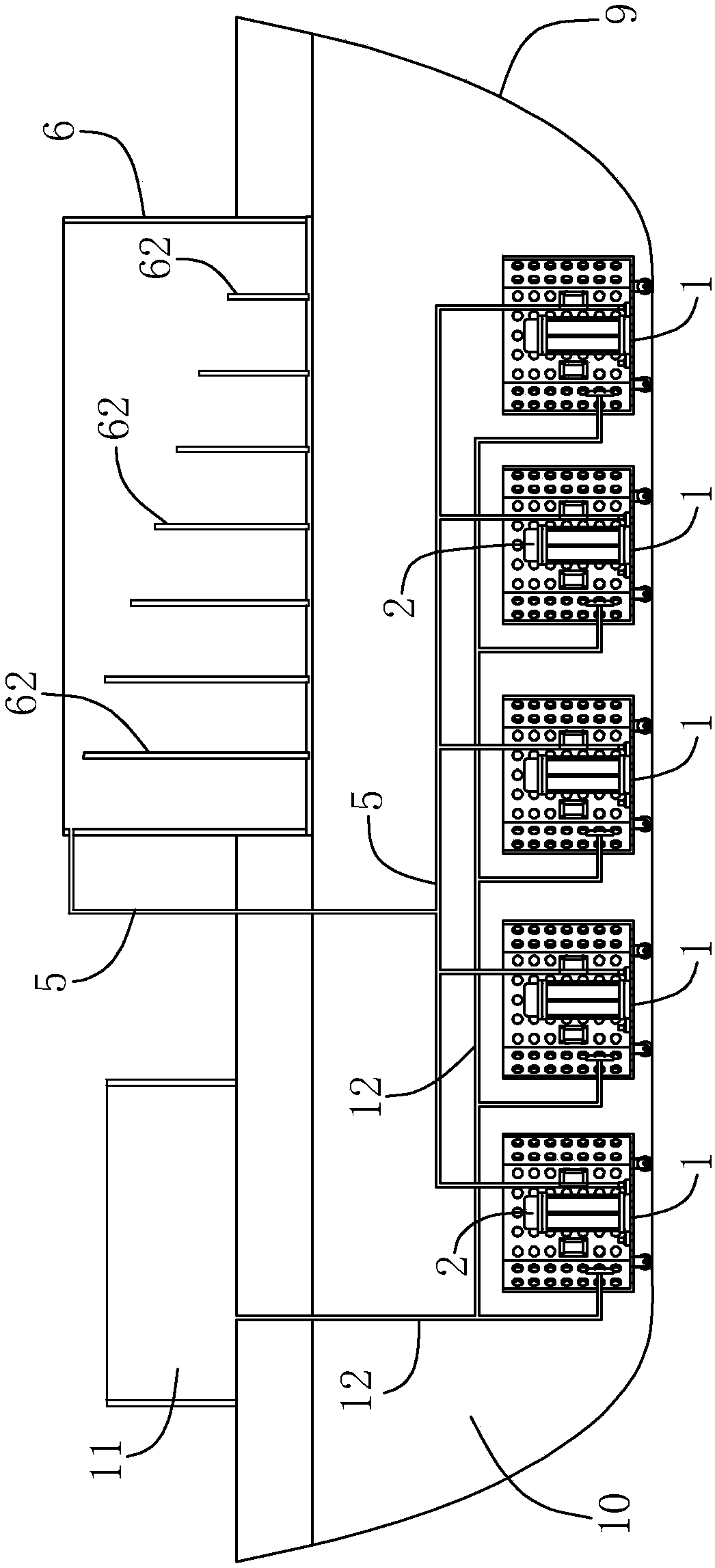

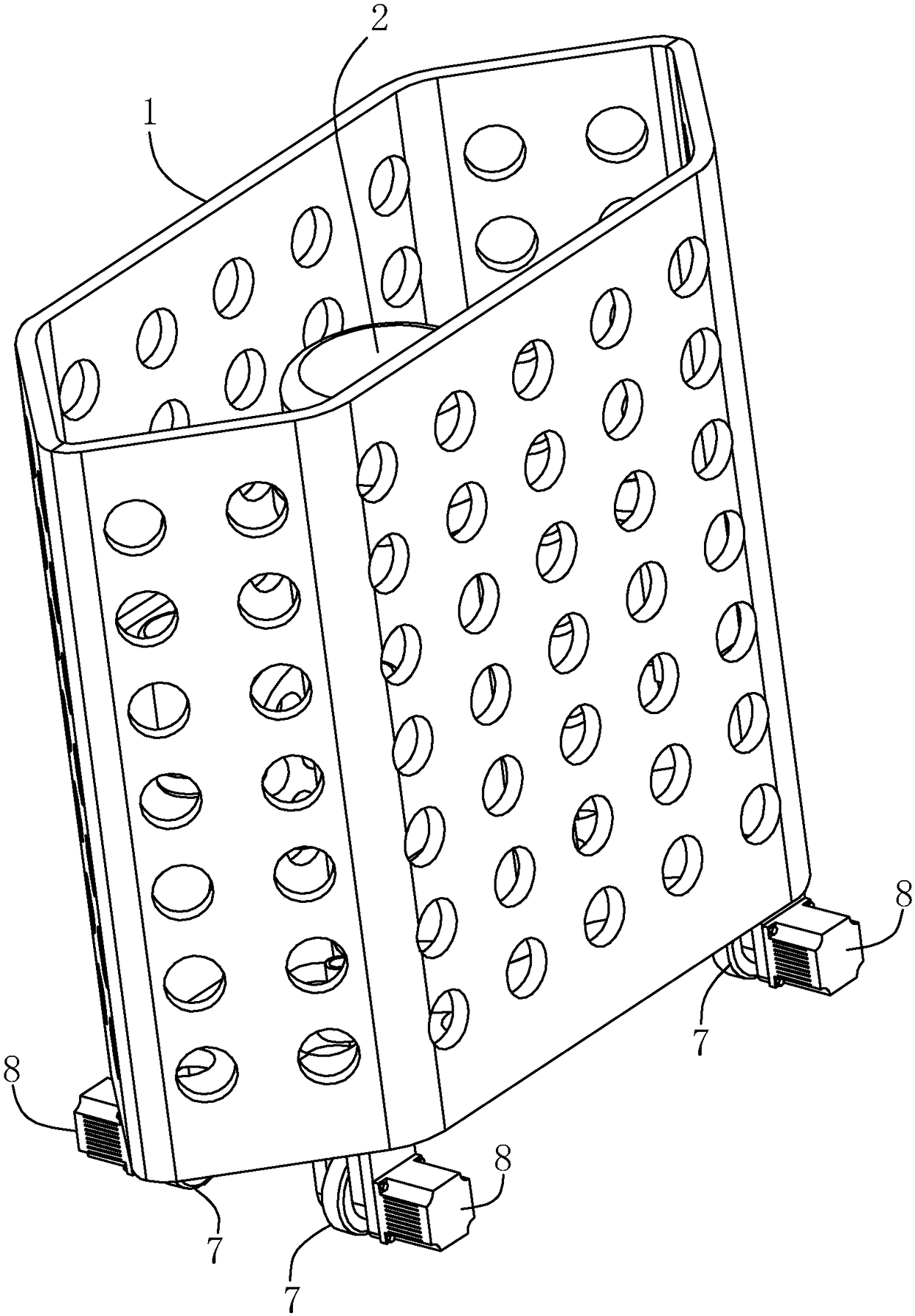

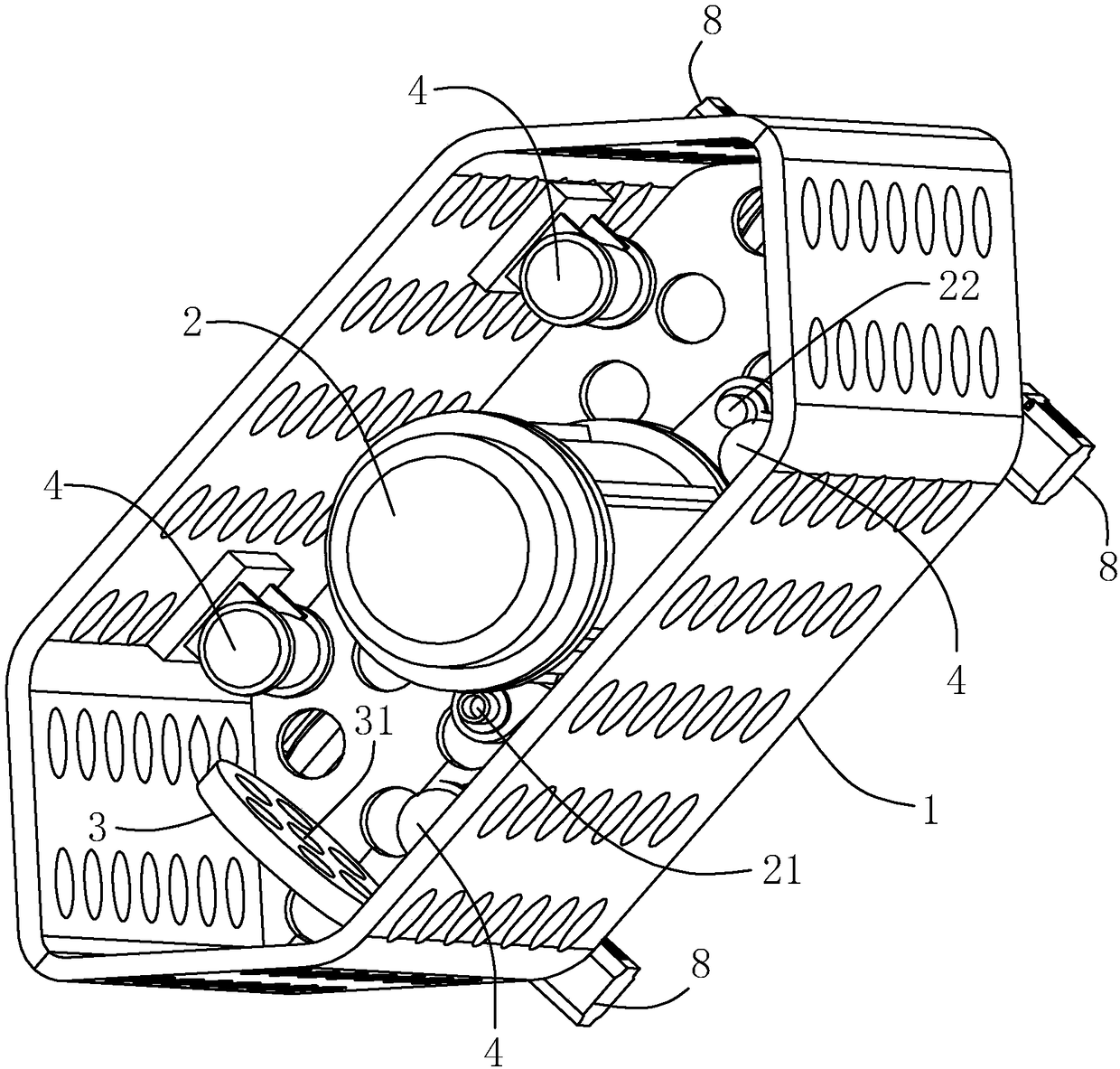

[0051] A crude oil storage tank cleaning system for FPSO in an offshore drilling platform, combined with Figure 1-Figure 3 As shown, it includes: basket 1, suction pump 2, water spraying part 3, vibration motor 4, pipe 5, separation tank 6, rolling parts 7, power source 8, cruise ship 9, crude oil storage 10, water supply system 11 , water pipe 12 and the control processing center, the control processing center controls the suction pump 2, the vibrating motor 4, the power source 8, the water supply system 11 to work together, the control processing center is specifically a control computer and is not shown in the accompanying drawings.

[0052] The crude oil storage bin 10 is located at the bottom of a cruise ship 9, the separation tank 6 and the water supply system 11 are arranged on the cruise ship 9, the water supply system 11 is specifically a water storage tank with a built-in water pump, and the water supply system 11 is connected to the image 3 The water spray part 3 ...

specific Embodiment 2

[0066] A crude oil storage bin cleaning system for FPSO in an offshore drilling platform, the difference from the specific embodiment 1 is that in combination with Image 6As shown, the rollers 7 are at least two groups of rollers arranged at the bottom of the basket 1. In this embodiment, the number of rollers is four, and the rollers are arranged on the output shaft of the drive motor and driven to rotate by the drive motor, and the drive motor The four rollers are driven to rotate synchronously through the sprocket transmission structure (the gear transmission structure or the pulley transmission structure can be replaced). The purpose of moving the basket 1 at the bottom of the crude oil storage silo 10 can be achieved through the cooperation of the roller with the drive motor. At the same time, the way of rolling friction is more labor-saving and energy-saving than the way of sliding friction, so that the above-mentioned movement process is simpler and more stable, especia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com