High-quality card protection membrane and preparation method thereof

A card protection film, high-quality technology, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of air bubbles, poor card protection film overmolding effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

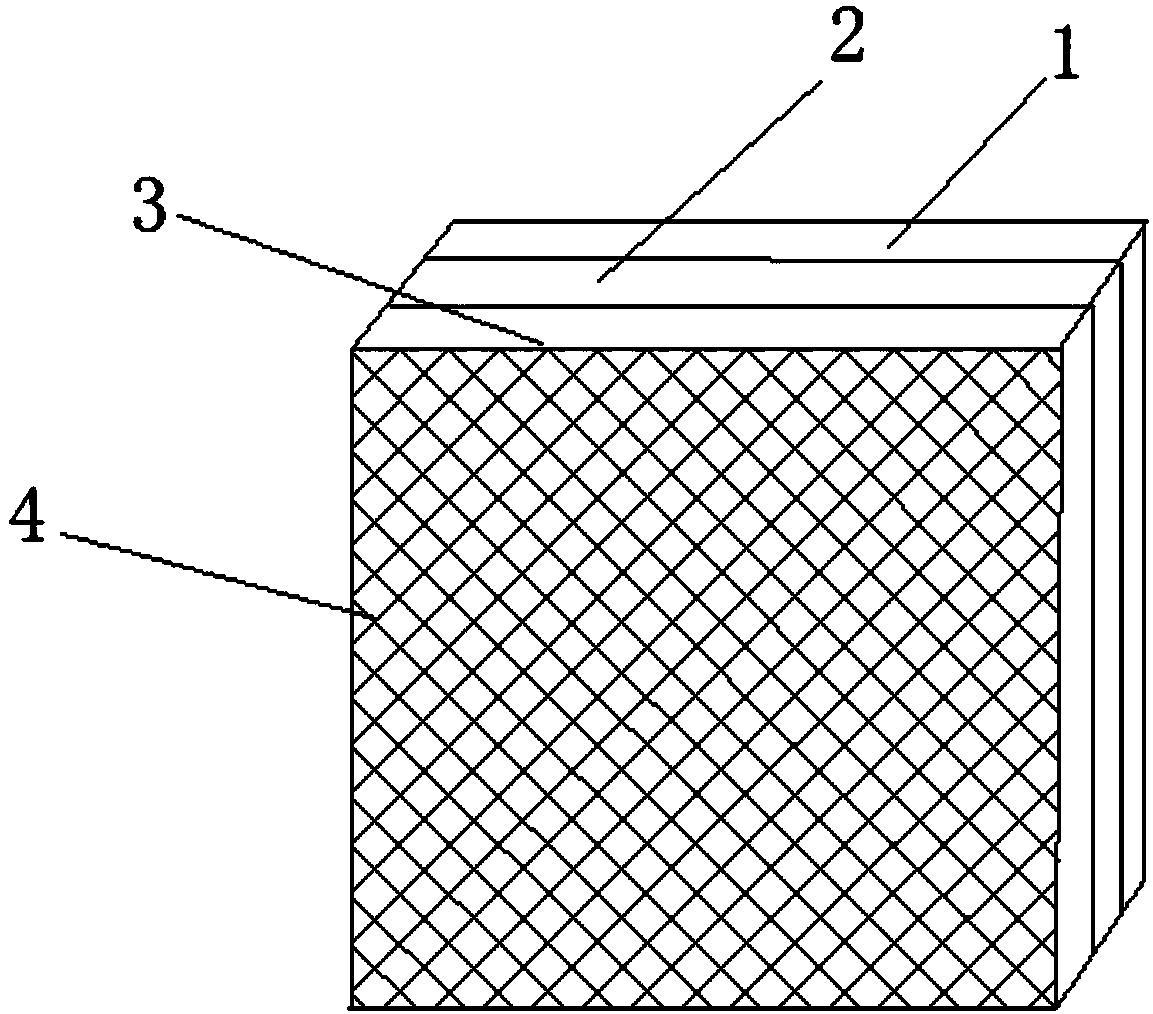

[0019] Implementation mode one: if figure 1 Shown, a kind of high-quality protective card film is made up of BOPET polyester film layer 1, polyethylene film layer 2 and EVA vinyl acetate copolymer film layer 3 successively, on the described EVA vinyl acetate copolymer film layer Permanent embossing is provided, and the permanent embossing is a rhombus lattice pattern 4 . The polyethylene film layer is an LDP low density polyethylene film layer. The preparation steps of the protective card film are;

[0020] A: The BOPET polyester film layer is prepared by biaxially stretching the BOPET polyester substrate;

[0021] B: The polyethylene melt flows out to the BOPET polyester film layer in step A through the mold, and is cooled by rollers, stretched and calendered to form a polyethylene film layer attached to the BOPET polyester film layer;

[0022] C: The melt of EVA vinyl acetate copolymer flows out to the polyethylene film layer in step B through the mold, and is cooled by r...

Embodiment approach 2

[0025] Embodiment 2: Different from Embodiment 1, the polyethylene melt is an LLDPE linear low-density polyethylene melt, and the polyethylene film layer is an LLDPE linear low-density polyethylene film layer.

Embodiment approach 3

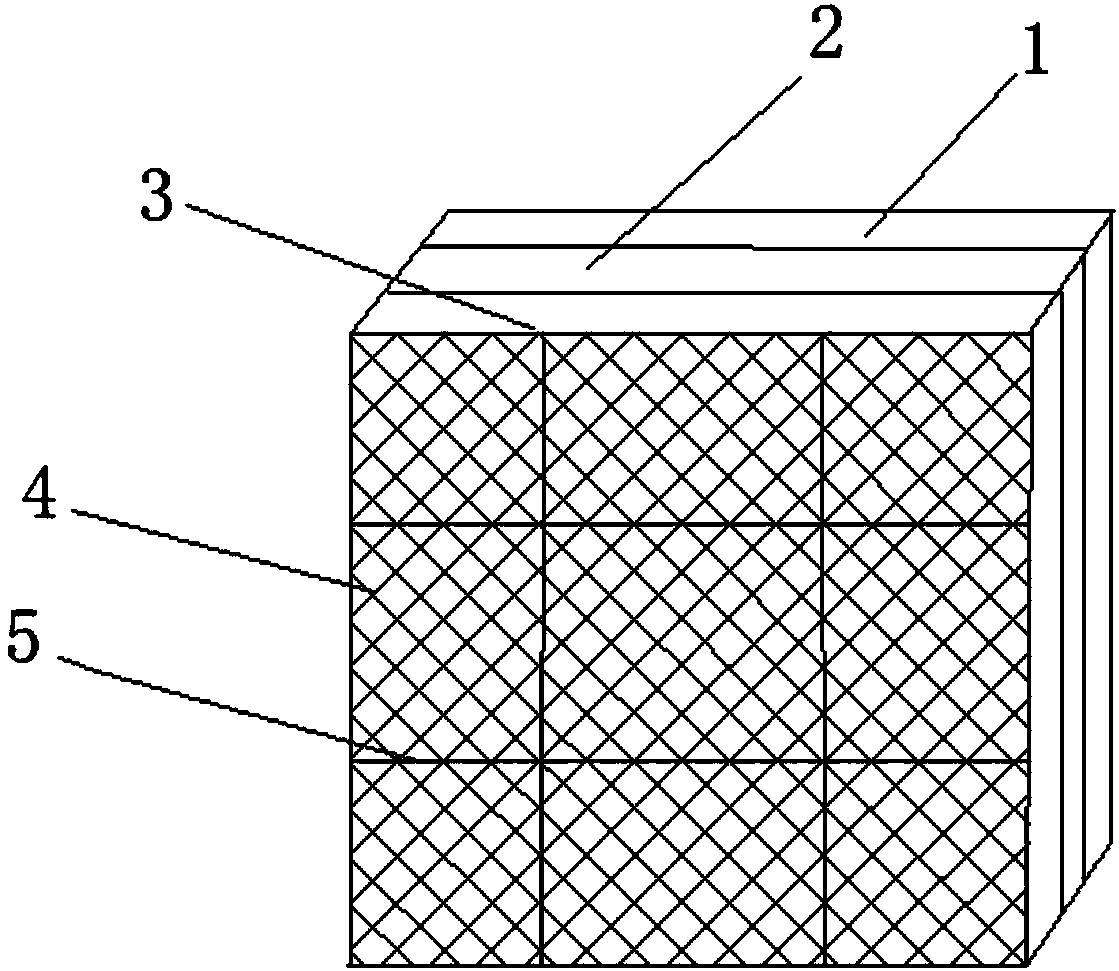

[0026] Implementation mode three: if figure 2 As shown, on the basis of Embodiment 1, equidistant vertical and horizontal scale lines 5 are also provided on the card protection film. The surface of the roller in the step C is also provided with equidistant vertical and horizontal scale convex lines.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com