Camera image conversion system for vacuum packaged image sensor chip

An image sensor and image conversion technology, which is used in image communication, parts of TV systems, parts of color TV, etc. It can solve the problem of changing the vacuum degree of the objective lens, affecting the accuracy and clarity of the objective lens, and it is difficult for users to know and other problems to achieve better results and clearer images.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings, wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower", "bottom" and "top" used in the following description refer to the Directions, the words "inner" and "outer" refer to directions toward or away from, respectively, the geometric center of a particular component.

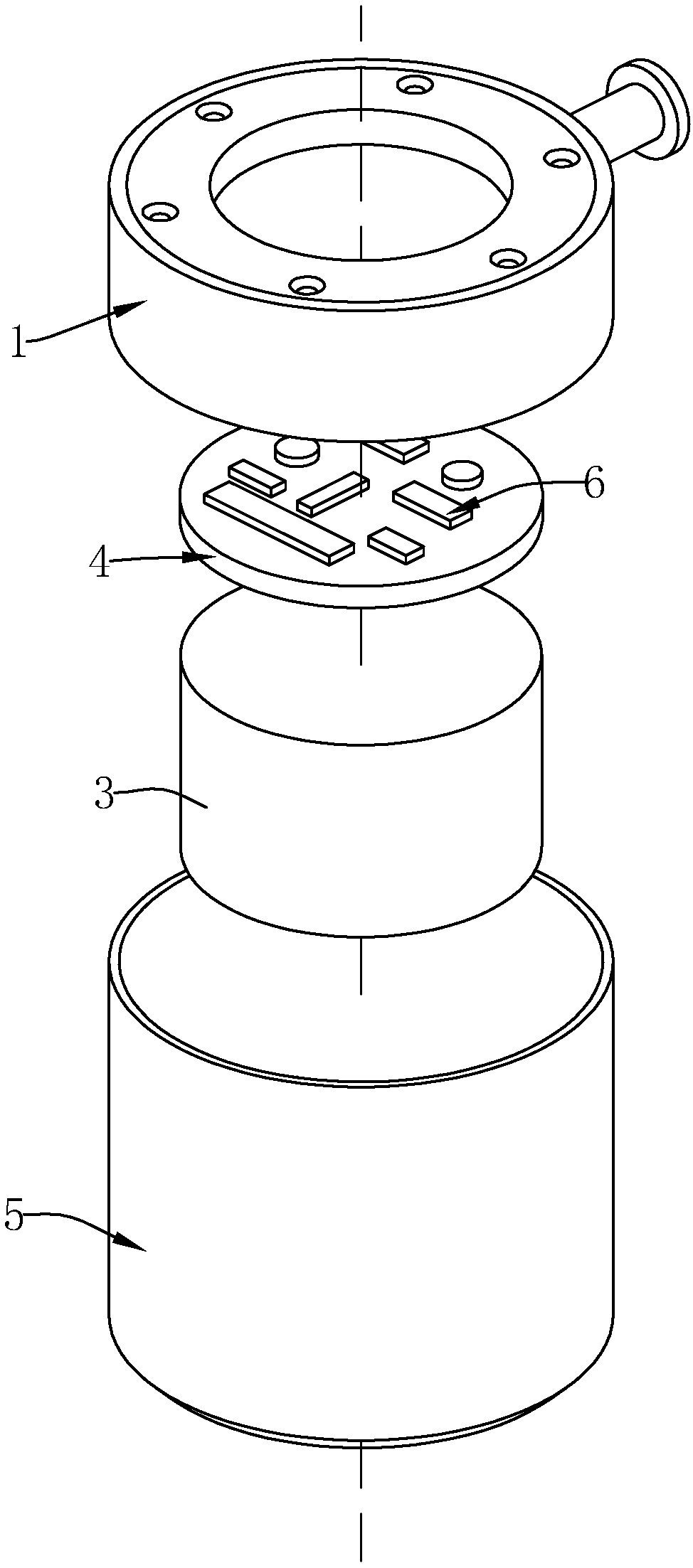

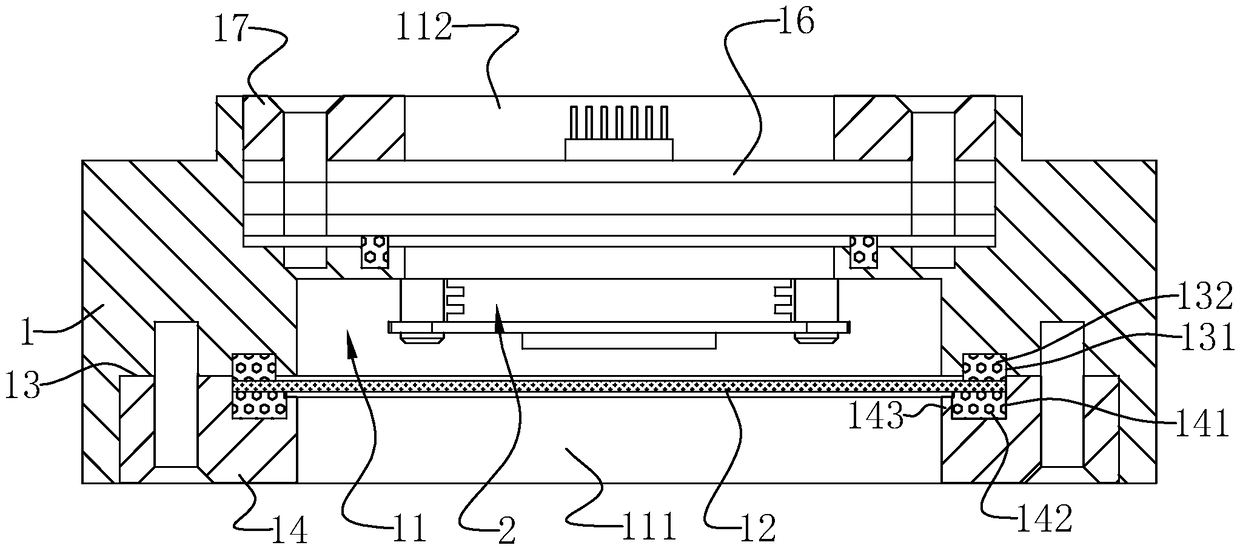

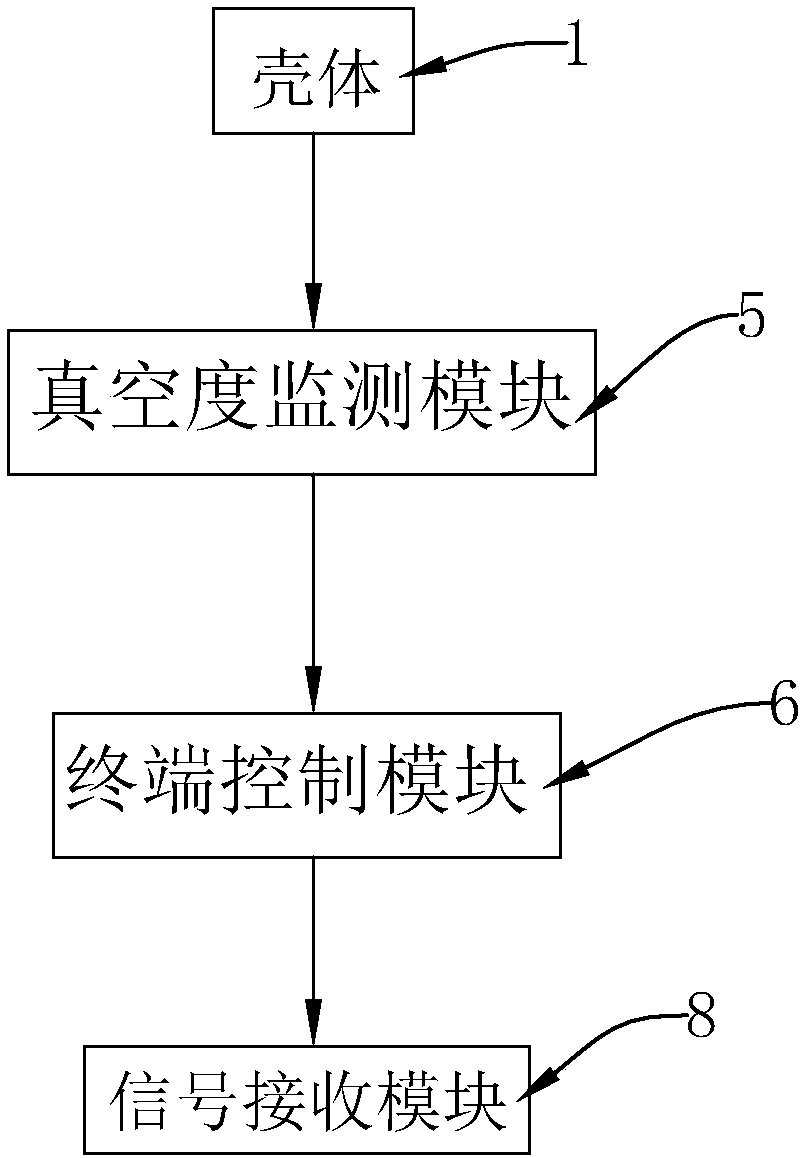

[0042] A camera image conversion system with a vacuum-encapsulated image sensor chip, combined with figure 1 and figure 2 As shown, it includes a housing 1, an image conversion module 2 arranged in the housing 1, a power supply module 3 for supplying power to the image conversion module 2, and a data processing module 4 for processing the signal of the image conversion module 2, wherein, in When in use, a lens is installed on the housing 1 and close to the image conversion module 2, the opti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com