Coupling structure dielectric resonator filter

A dielectric resonator and coupling structure technology, applied in the microwave field, can solve the problems of increased size and processing difficulty, complexity, and large filter structure size, and achieve the effects of miniaturization, increased transmission zero point, and improved out-of-band suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

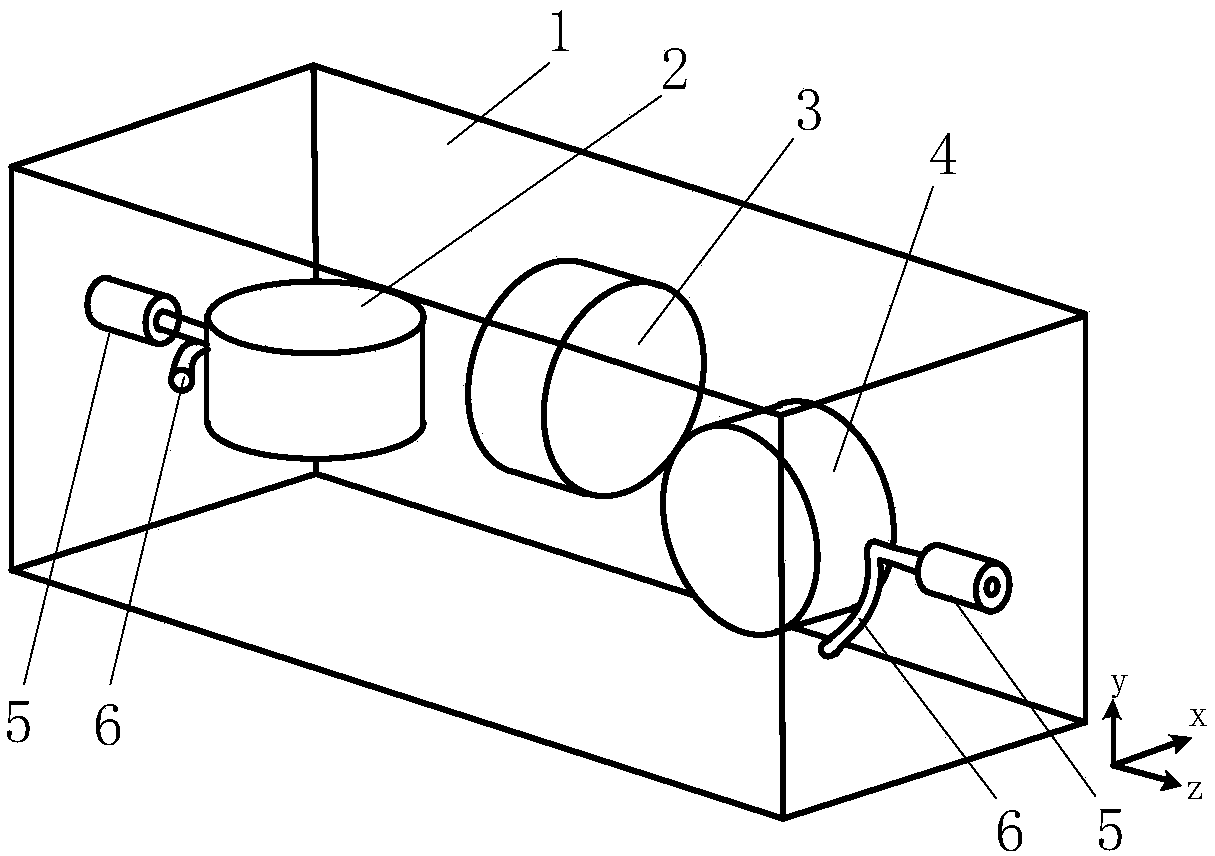

[0025] refer to figure 1 , the present invention includes a rectangular waveguide 1 with both ends closed, and a first dielectric resonator 2, a second dielectric resonator 3, a third dielectric resonator 4 fixed in sequence in the cavity of the rectangular waveguide 1, and two dielectric resonators fixed in the rectangular waveguide 1. Terminal radio frequency connector 5 and the loop feeder 6 connected on the radio frequency connector 5;

[0026] The rectangular waveguide 1 adopts a square waveguide with a detachable top cover, the side length of the square is a, a=31.6, and through holes are punched at both ends to facilitate the assembly of the radio frequency connector 5;

[0027] The first dielectric resonator 2, the second dielectric resonator 3 and the third dielectric resonator 4 adopt the same cylindrical structure, and all work on the TE 01δ mode, and fixed in the rectangular waveguide 1 with a foam with a relative permittivity of 1, with a thickness of H=8 and a r...

Embodiment 2

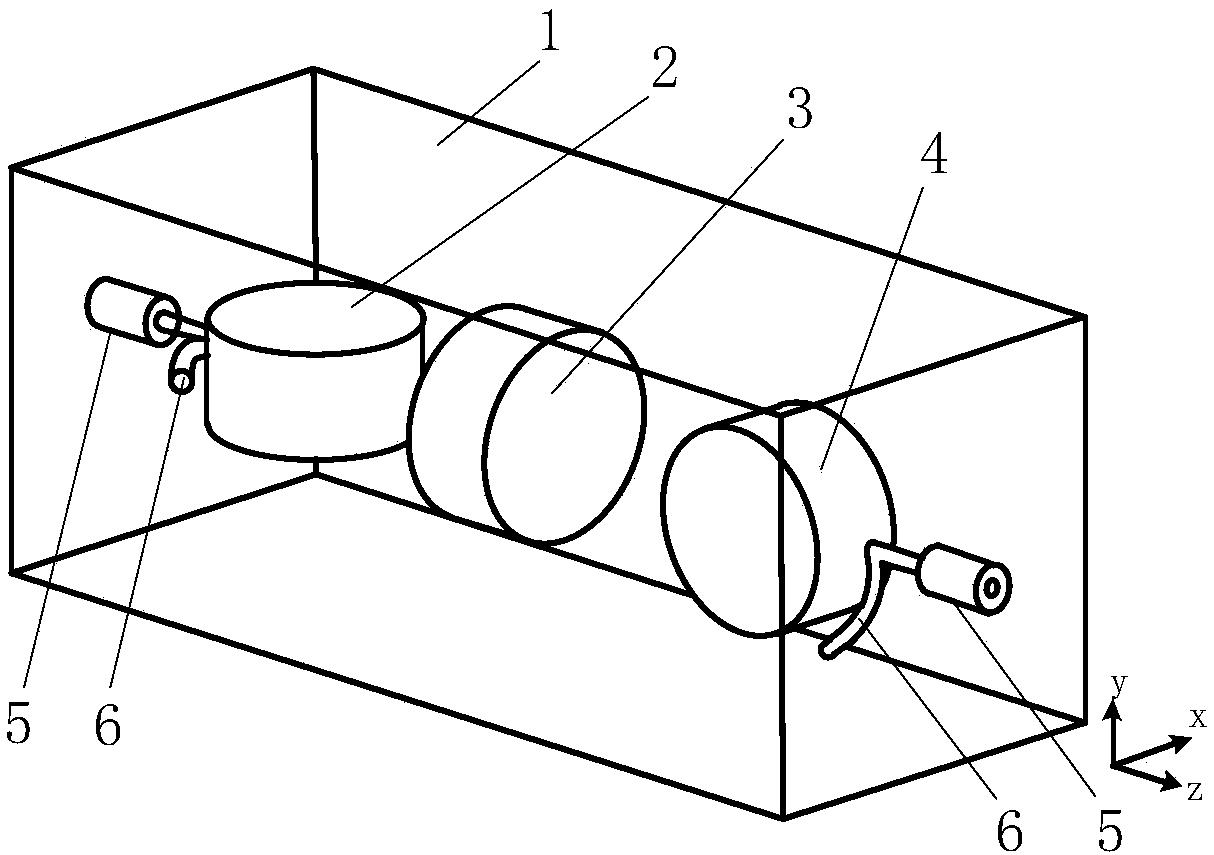

[0036] refer to figure 2 , the present invention includes a rectangular waveguide 1 with both ends closed, and a first dielectric resonator 2 fixed in the cavity of the rectangular waveguide 1, a third dielectric resonator 4, and a radio frequency connector 5 fixed at both ends of the rectangular waveguide 1 and connected to the Loop feeder 6 on the radio frequency connector 5;

[0037] The rectangular waveguide 1 with both ends closed, and the first dielectric resonator 2, the second dielectric resonator 3, the third dielectric resonator 4 fixed in sequence in the cavity of the rectangular waveguide 1, and the radio frequency The connector 5 and the loop feeder 6 connected to the radio frequency connector 5 are the same as in Embodiment 1;

[0038] The difference from Embodiment 1 is that the second dielectric resonator 3 is offset from the axis of the transmission direction of the rectangular waveguide 1, and the offset point is located on the bisector of the angle between...

Embodiment 3

[0041] The present invention includes a rectangular waveguide 1 with both ends closed, and a first dielectric resonator 2 fixed in the cavity of the rectangular waveguide 1, a third dielectric resonator 4, and a radio frequency joint 5 fixed at both ends of the rectangular waveguide 1 and connected to a radio frequency Loop feeder 6 on connector 5;

[0042] The rectangular waveguide 1 with both ends closed, and the first dielectric resonator 2, the second dielectric resonator 3, the third dielectric resonator 4 fixed in sequence in the cavity of the rectangular waveguide 1, and the radio frequency The connector 5 and the loop feeder 6 connected to the radio frequency connector 5 are the same as in Embodiment 1;

[0043] The difference from Embodiment 1 is that the second dielectric resonator 3 is offset from the axis of the transmission direction of the rectangular waveguide 1, and the offset point is located on the bisector of the angle between the x-axis and the y-axis in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com