FRP (fiber reinforced plastic) lossless multi-electrode sensing structure for intelligent tensioning and CFRP (carbon fiber reinforced plastic) rib manufacturing method

An intelligent tensioning and multi-electrode technology is applied in the direction of material analysis, measuring devices, and instruments through electromagnetic means, which can solve problems that have not been effectively solved, and achieve the effects of easy implementation, accurate real-time monitoring, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

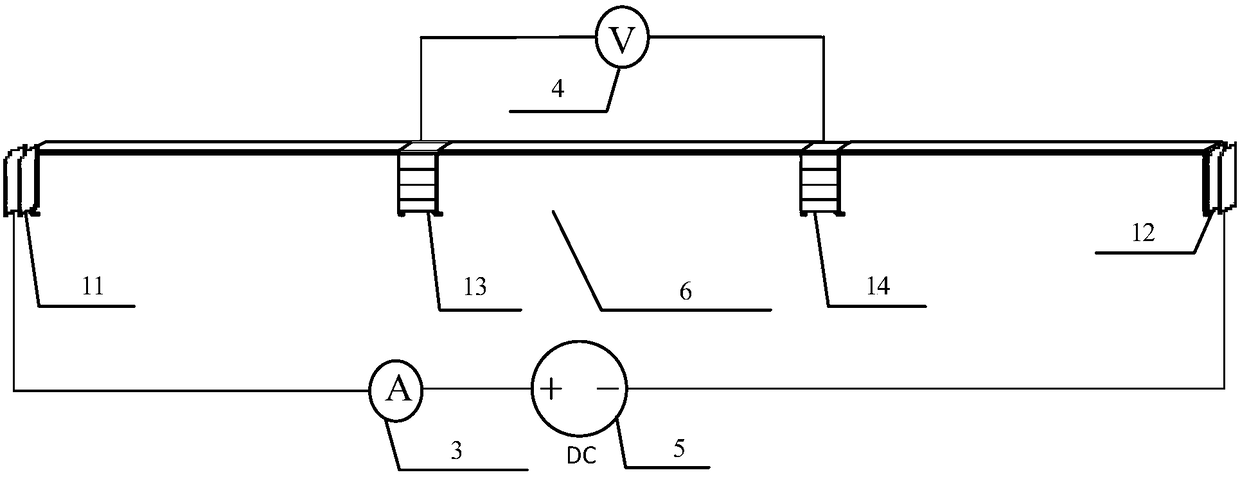

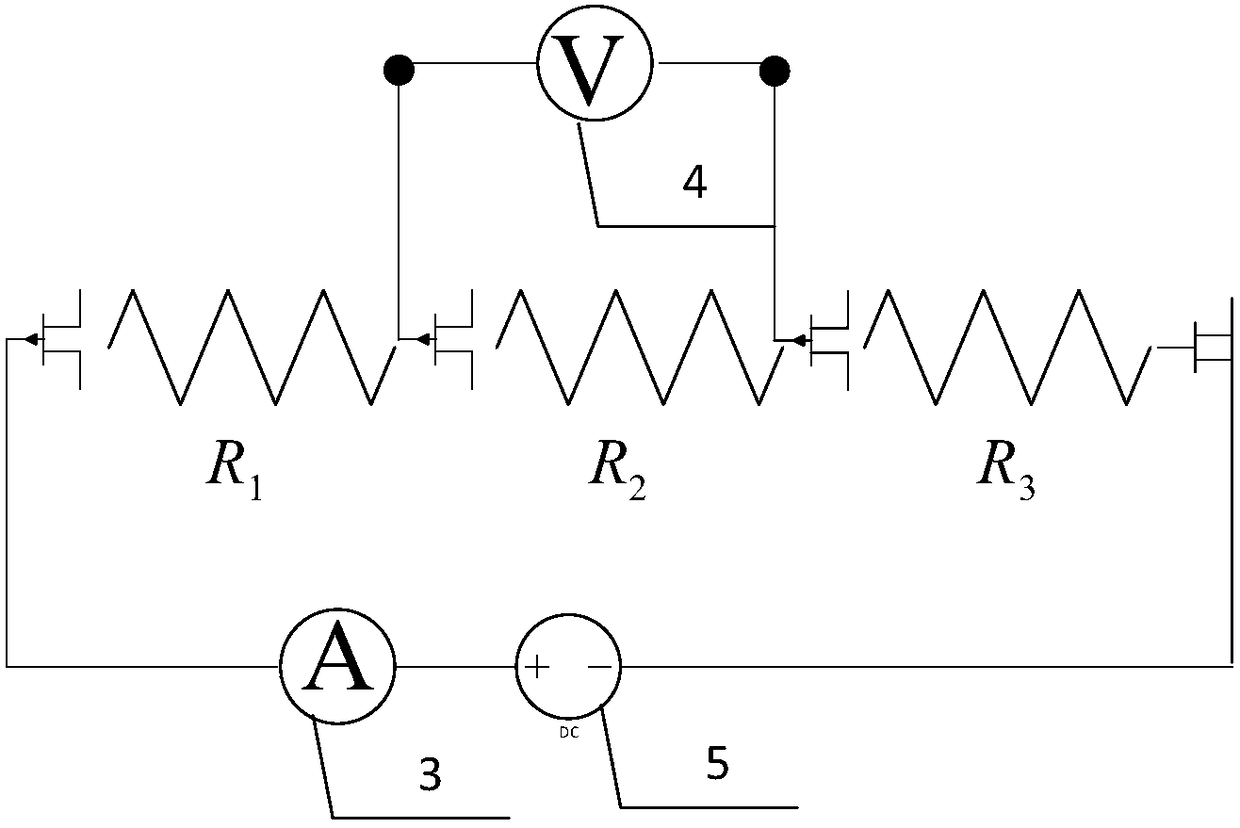

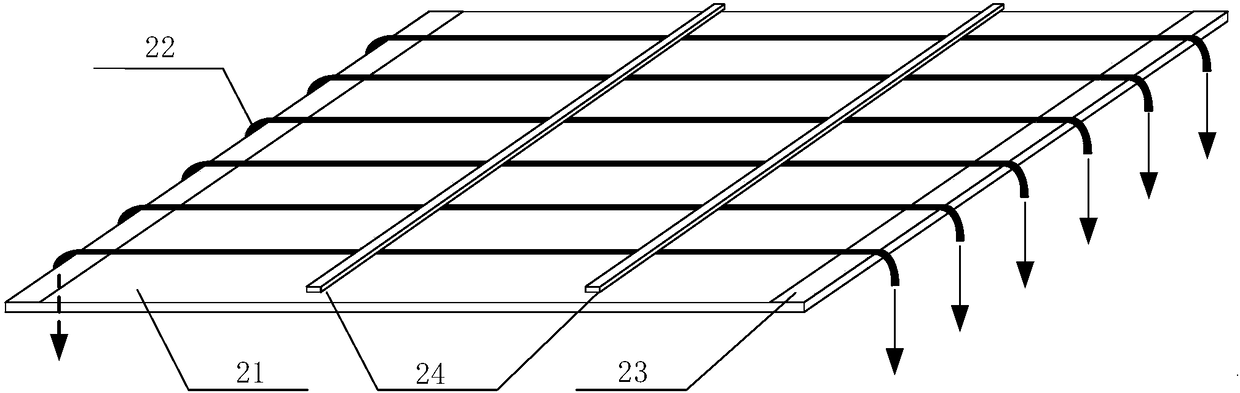

[0025] see figure 1 and figure 2 , the FRP non-destructive multi-electrode sensing structure used for intelligent tensioning in this embodiment is:

[0026] Each electrode is set in the CFRP tendon, including terminal electrodes and internal electrodes, and the terminal electrodes are the first electrodes 11 and the second electrodes 12 at the left and right ends of the CFRP tendons; the internal electrodes are arranged inside the CFRP tendons, And the third electrode 13 and the fourth electrode 14 at different axial positions are in one-to-one correspondence.

[0027] The detection circuit is set by connecting the constant current power supply 5 between the first electrode 11 and the second electrode 12, and setting the ammeter 3 in series in the current output circuit of the constant current power supply 5; between the third electrode 13 and the fourth electrode 14 A voltage detection circuit is set between them, and a voltmeter 4 is set in the voltage detection circuit; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com