Color-change-resistant anti-bacterial polyamide fiber

A nylon fiber, discoloration-resistant technology, applied in the field of antibacterial fiber preparation, can solve the problems of complex preparation process and unknown effect, and achieve the effects of simple preparation process, stable and durable antibacterial performance, and excellent discoloration resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

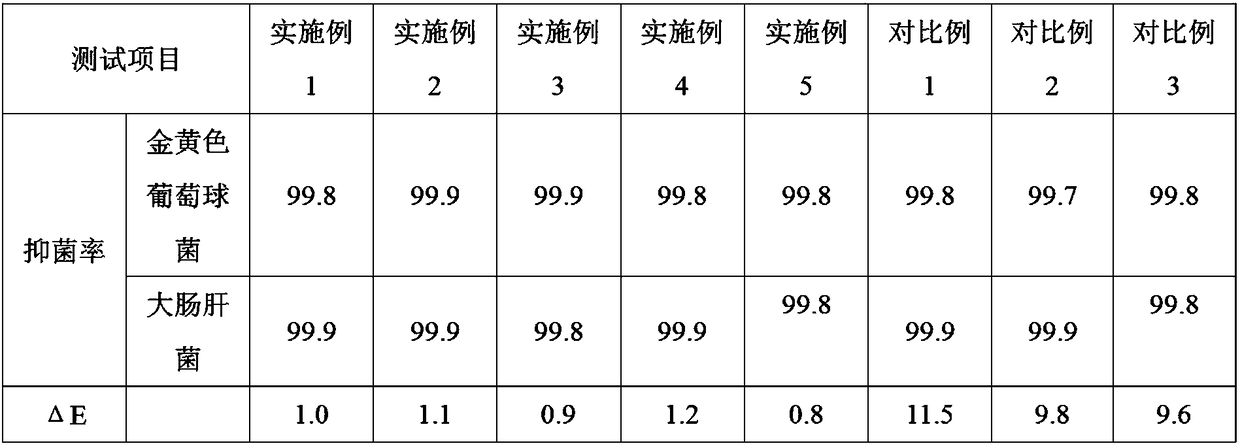

Examples

Embodiment 1

[0031] Mix 8.5 kg of PA12 with 1.5 kg of silver-loaded zeolite antibacterial agent, extrude and granulate with a twin-screw extruder with a screw diameter of 35, and the screw temperatures are 230°C, 240°C, 250°C, 230°C, 230°C, 230°C ℃, 230℃, water-cooled strands cut into antibacterial masterbatch, dried at 100℃ for 8 hours, added antibacterial masterbatch to PA6 spinning in proportion, obtained antibacterial agent content 1%, specification 70d / 24f antibacterial PA6 silk.

Embodiment 2

[0033] Mix 7.5 kg of PA12 with 2.5 kg of silver-loaded zeolite antibacterial agent, extrude and granulate with a twin-screw extruder with a screw diameter of 35, and the screw temperatures are 230°C, 240°C, 250°C, 230°C, 230°C, 230°C ℃, 230℃, water-cooled strands, cut into antibacterial masterbatch, dried at 100℃ for 8 hours, added antibacterial masterbatch into PA6 spinning in proportion, obtained 1% antibacterial agent content, and obtained 70d / 24f antibacterial PA6 silk.

Embodiment 3

[0035] Mix 8.5 kg of PA11 with 1.5 kg of silver-loaded zirconium phosphate antibacterial agent, extrude and granulate with a twin-screw extruder with a screw diameter of 35, and the screw temperatures are 230°C, 240°C, 250°C, 230°C, 230°C, 230°C, 230°C, water-cooled strands cut into antibacterial masterbatches, dried at 100°C for 8 hours, added antibacterial masterbatches in proportion to PA6 spinning, the content of antibacterial agent was 1%, and the specifications were 70d / 24f antibacterial PA6 filaments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com