Copper alloy material and application thereof

A technology of copper alloy and weight percentage, applied in the field of copper alloy, can solve the problems of poor stress relaxation resistance, low conductivity of phosphor bronze, difficult to meet, etc., achieve yield strength and bending processing performance improvement, and realize strength and bending performance , to overcome the effect of increased processing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

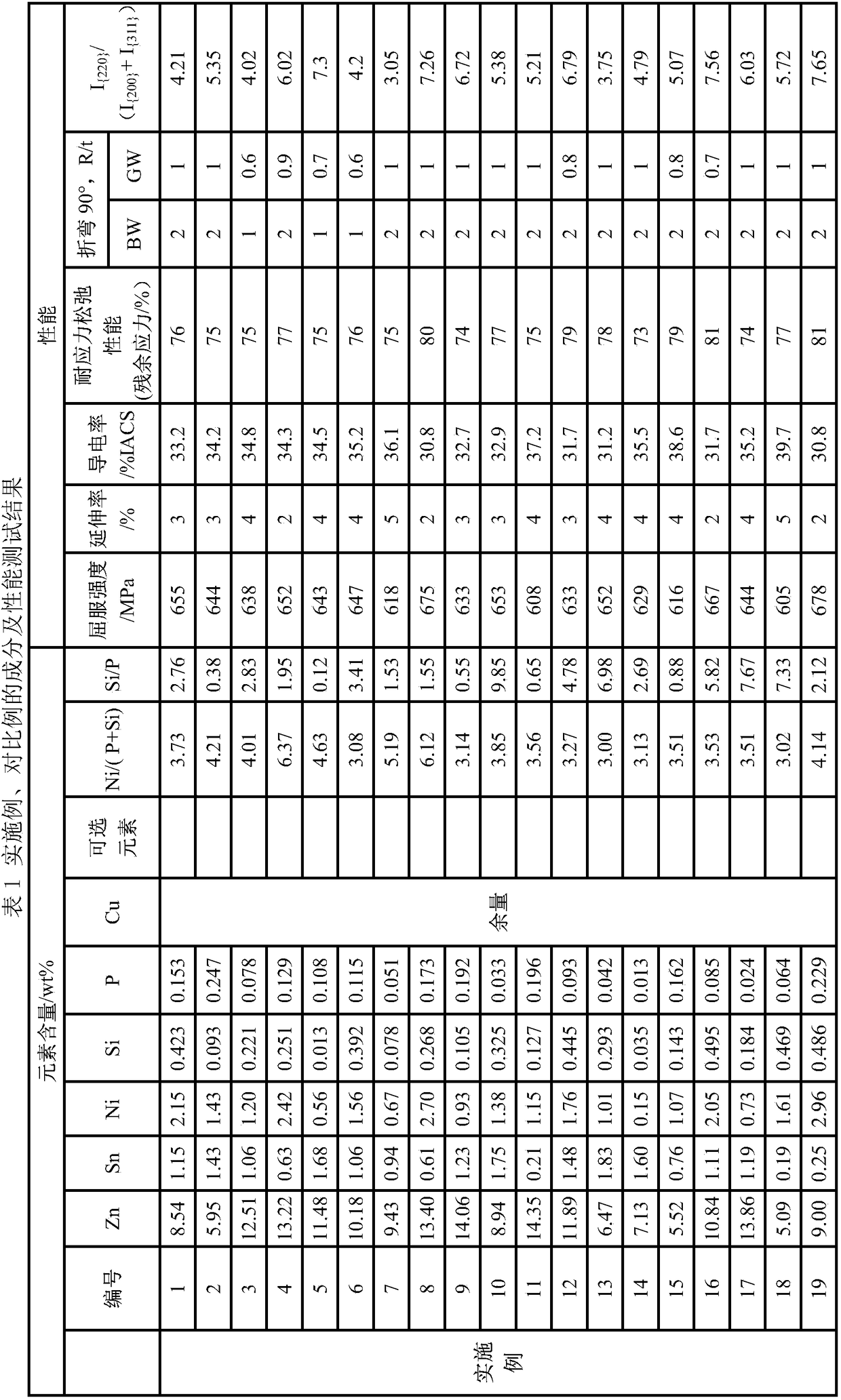

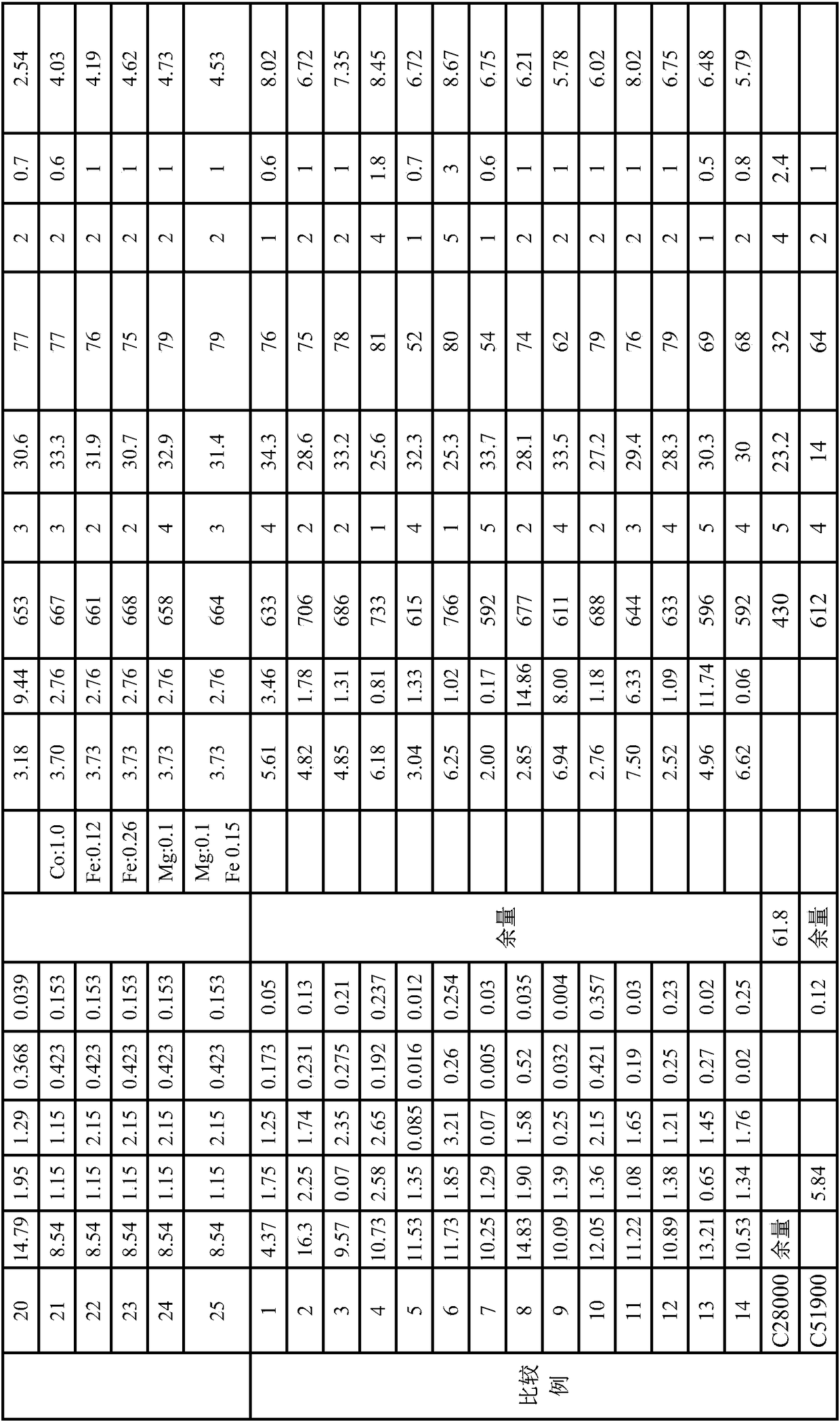

[0038] Below in conjunction with embodiment the present invention is described in further detail.

[0039] According to the composition in Table 1, the copper alloy of the composition combination shown in Table 1 was melted at 1150° C., and an ingot having a specification of 170 mm×320 mm was produced. After the above ingot was kept at 850°C for 5 hours, it was hot-rolled to a thickness of 16.5mm; then, it was face milled to a thickness of 15mm, and then cold-rolled to a thickness of 2mm; then the cold-rolled The plate was heated to 440°C, held for 8 hours, and subjected to the first aging; the aged material was subjected to the second cold rolling to 0.035mm, and then the second aging treatment was carried out at 400°C for 8 hours; finally Finish cold rolling is carried out, and the rolling target plate thickness is 0.2 mm; after finish cold rolling, it is kept at 210° C. for 4 hours for low-temperature annealing to obtain a strip sample.

[0040] For the prepared strip samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com