Preparation method of pressure sensitive adhesive for polaroid protection film and protection film thereof

A technology of protective film and pressure-sensitive adhesive, applied in pressure-sensitive films/sheets, adhesives, film/sheet-like adhesives, etc. Excellent conductivity and electrical conductivity, saving the effect of glue dispensing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

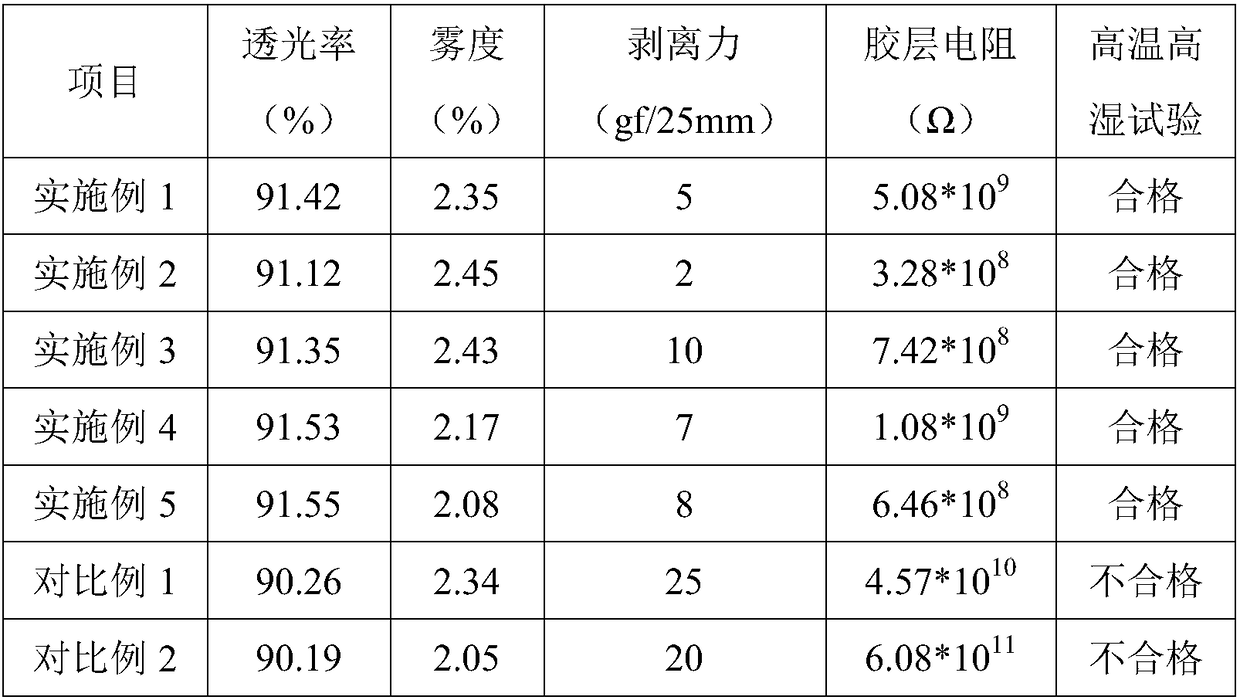

Examples

Embodiment 1

[0032] Mix 10 g of lauryl methacrylate, 10 g of ethyl methacrylate, 5 g of styrene, 4 g of trifluoroethyl methacrylate, and 0.5 g of azobisisobutyronitrile uniformly to obtain a pre-prepared solution.

[0033] 10g of ethyl acetate, 15g of butyl acetate, and 5g of acetone were added to the reactor, the temperature was raised to 75°C, 7.38g of prefabricated solution was added to the reactor, and the reaction was incubated for 25min; 0.8g of trimethylolpropane triacrylate, 0.8 g of dimethyl (dimethylamino) vinyl silane, 0.53 g of polythiophene, and 0.27 g of silver nanowires were added to the remaining pre-prepared solution to obtain an intermediate solution.

[0034] Add the intermediate solution to the reactor, keep the reaction for 1.5h, cool down to 50°C, then add 50g ethyl acetate, 75g butyl acetate, 10g acetone, 15g butanone, 1g MF-K60X (Japan Asahi Kasei Chemical), get polarizer protection Pressure sensitive adhesive for film.

[0035] Coat the pressure-sensitive adhesive...

Embodiment 2

[0037] 20 g of lauryl methacrylate, 20 g of 2-ethylhexyl acrylate, 10 g of ethyl methacrylate, 5 g of styrene, 2 g of trifluoroethyl acrylate, and 1 g of dibenzoyl peroxide were mixed uniformly to obtain a pre-prepared solution.

[0038] 64g of ethyl acetate, 10g of acetone and 6g of butanone were added to the reactor, the temperature was raised to 85°C, 9.67g of prefabricated solution was added to the reactor, and the reaction was kept for 15min; 2g of trimethylolpropane triacrylate, 1g of dimethacrylate Propylene glycol diacrylate, 0.7g dimethyl(dimethylamino)vinylsilane, 0.7g vinyltriacetylsilane, 0.6g diethylmethylvinylsilane, 1.67g polythiophene, 0.33g nano silver wire were added into the remaining prefabricated solution to obtain an intermediate solution.

[0039] Add the intermediate solution to the reactor, keep the reaction temperature for 3h, cool down to 60°C, then add 80g ethyl acetate, 20g acetone, 20g butanone, 4g BL3370MPA (Bayer) to obtain a pressure-sensitive ...

Embodiment 3

[0042] 30g 2-ethylhexyl acrylate, 5g ethyl methacrylate, 5g styrene, 3g trifluoroethyl methacrylate, 3g trifluoroethyl acrylate, 0.3g azobisisobutyronitrile, 0.3g The dibenzoyl oxide is mixed uniformly to obtain a pre-prepared solution.

[0043] 45g of butyl acetate and 15g of butanone were added to the reactor, the temperature was raised to 80°C, 9.32g of prefabricated solution was added to the reactor, and the reaction was kept for 25min; 1.5g of dipropylene glycol diacrylate, 1g of dimethyl (dimethyl) Amino) vinylsilane, 0.5 g of diethylmethylvinylsilane, 1.2 g of polythiophene, and 0.3 g of silver nanowires were added to the remaining pre-prepared solution to obtain an intermediate solution.

[0044] Add the intermediate solution to the reactor, keep the reaction for 2h, cool down to 55℃, then add 20g ethyl acetate, 40g butyl acetate, 20g butanone, 1g MF-K60X (Asahi Kasei Chemical), 1g BL3370MPA (Bayer), 1g B1358 (Degu Sa) to obtain a pressure-sensitive adhesive for polar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com