Preparation method of nano-coating

A nano-type, coating technology, applied in conductive coatings, antifouling/underwater coatings, and biocide-containing paints, etc., can solve the problems of poor antibacterial effect, low sterilization rate, and high cost, and achieve good antibacterial effect and lightening. The construction is cumbersome and the waterproof effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

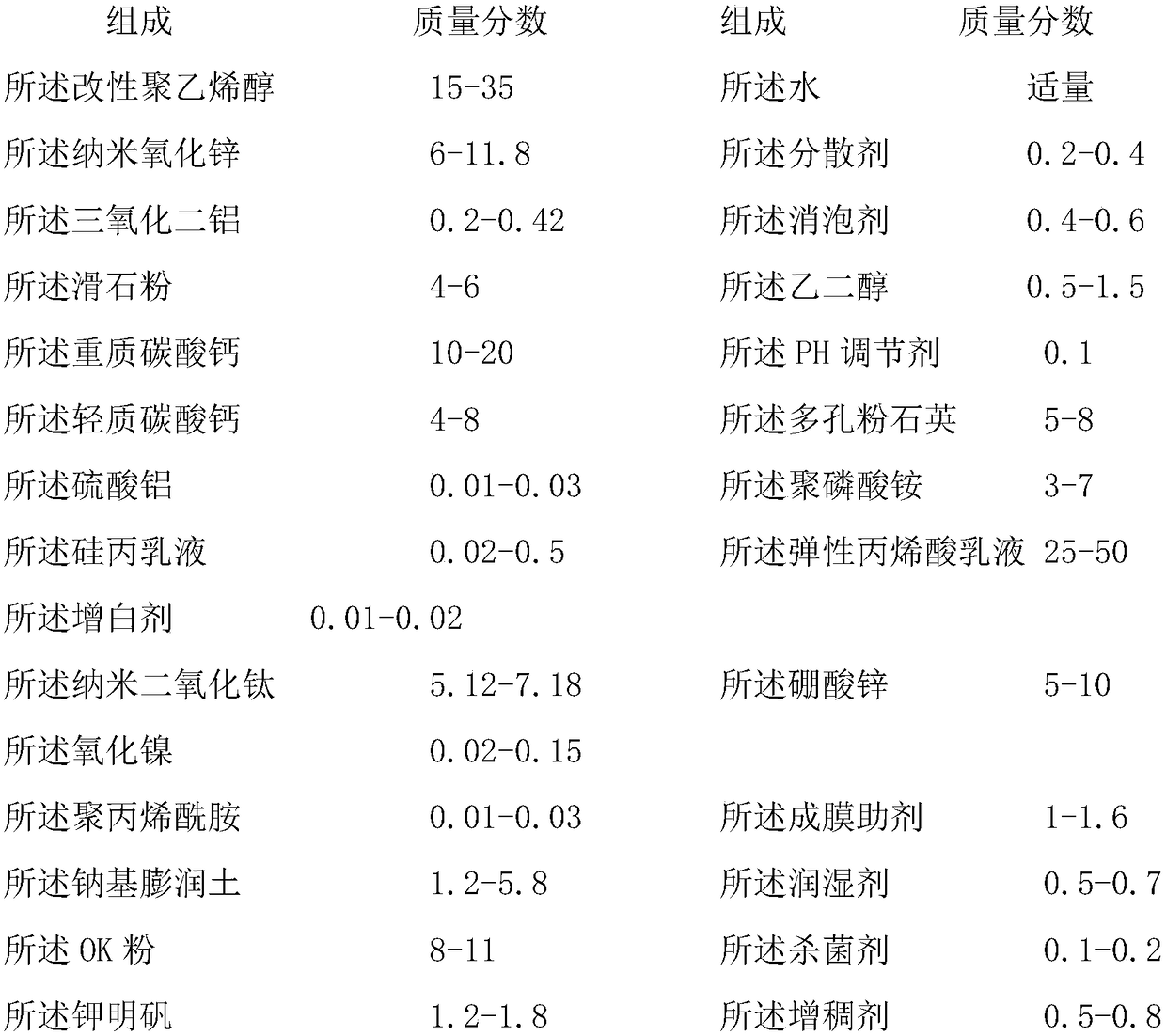

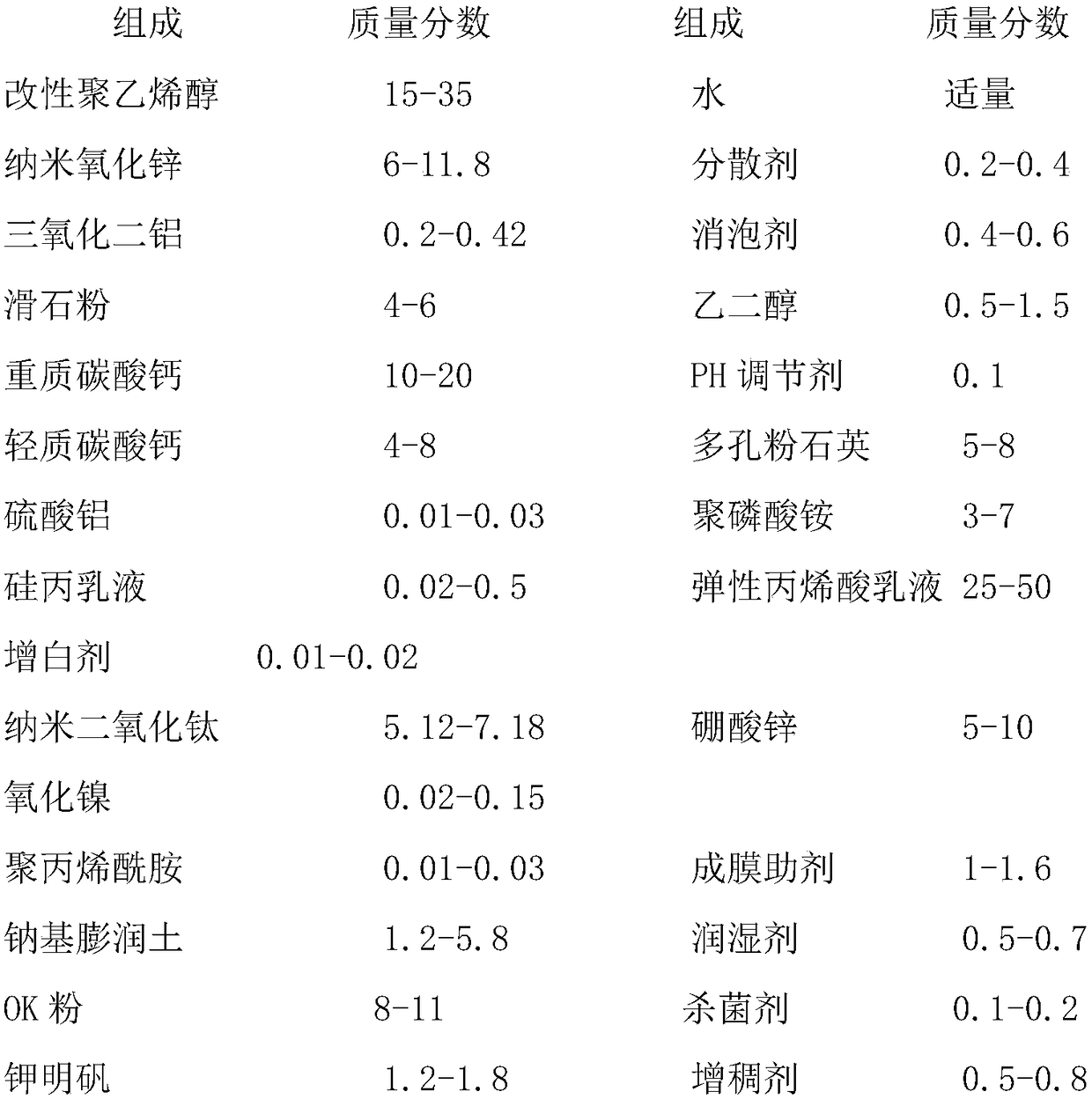

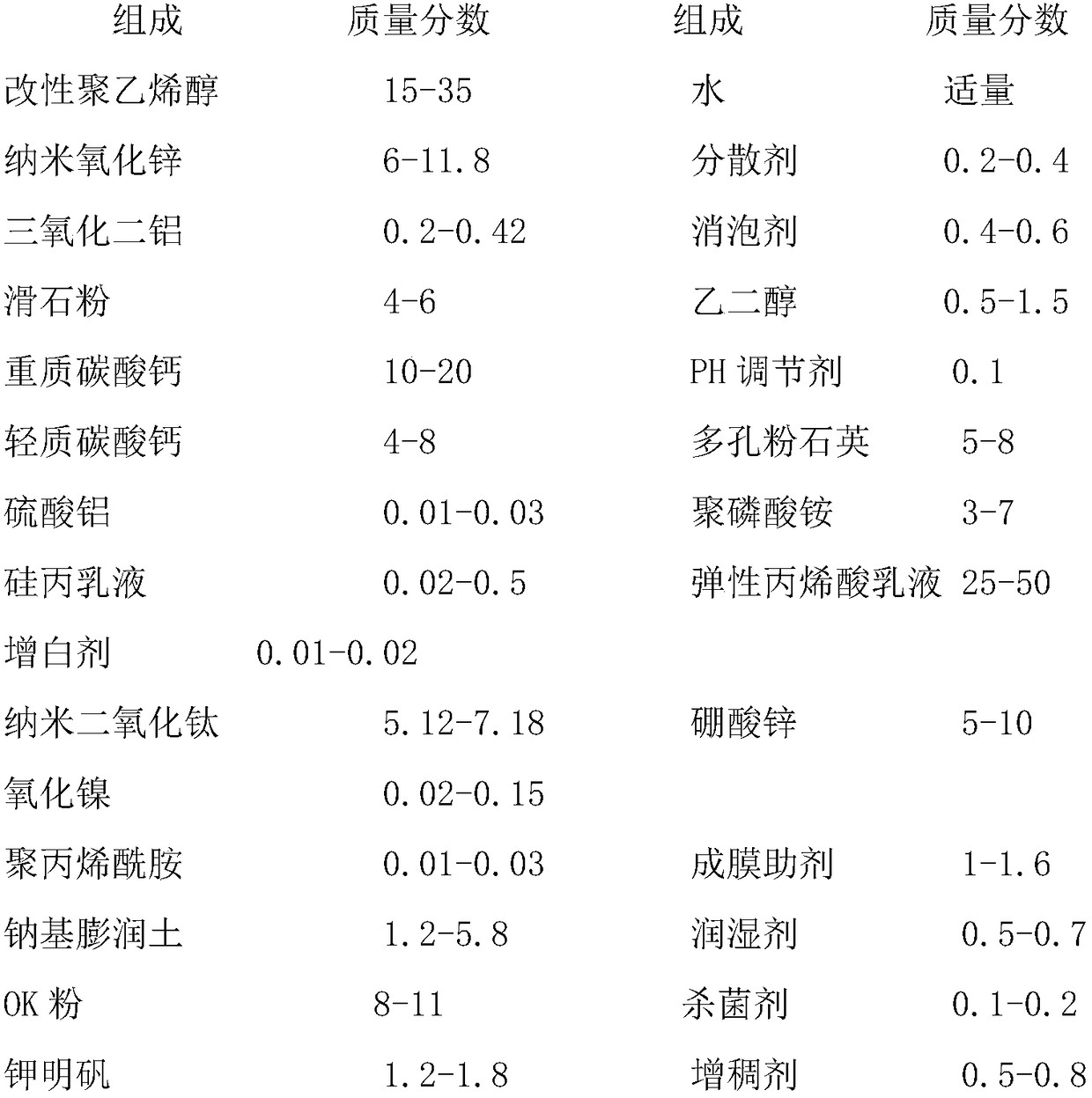

[0022] The invention provides a preparation method of nano-type coating, comprising modified polyvinyl alcohol, nano zinc oxide, aluminum oxide, talcum powder, heavy calcium carbonate, light calcium carbonate, aluminum sulfate, silicon acrylic emulsion, whitening Agent, nano titanium dioxide, nickel oxide, polyacrylamide, sodium bentonite, OK powder, potassium alum, water, dispersant, defoamer, ethylene glycol, PH regulator, porous powder quartz, ammonium polyphosphate, elastic acrylic emulsion , zinc borate, coalescent, wetting agent, bactericide and thickener, the coating consists of the following formula:

[0023]

[0024] Preparation method:

[0025] (1) After fully dissolving modified polyvinyl alcohol and an appropriate amount of water at 65-70°C in a stirred tank, then add nano-zinc oxide, aluminum oxide, dispersant, defoamer, ethylene glycol and pH regulator Add them separately and stir well to form the base material.

[0026] (2) Add the prepared base material in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com