Green environment-friendly sterilizing flocculant

A green and environmentally friendly flocculant technology, applied in the fields of fungicides, flocculation/sedimentation water/sewage treatment, biocides, etc., can solve the problems of not being widely used, loss of flocculation activity, poor flocculation effect, etc. The effect of increasing economic benefits and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

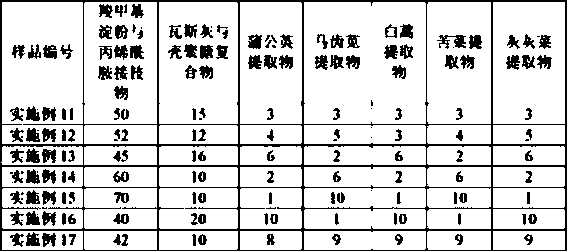

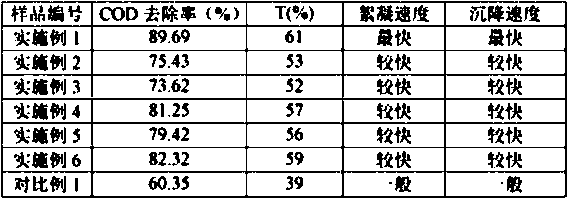

Examples

Embodiment 1

[0056] Preparation of carboxymethyl starch grafted acrylamide copolymer: in parts by weight, add 2 parts of carboxymethyl starch to 70 parts of deionized water, heat to 85° C., and keep stirring under nitrogen protection for gelatinization for 1 hour. Cooling; add the initiator potassium persulfate afterwards, the initiator concentration is 5.5×10 4 mol / L; then add 9 parts of monomeric acrylamide, and the reaction time is 4 hours at 50 degrees Celsius. After the reaction is completed, the product is washed with absolute ethanol, and the product is dried under reduced pressure to constant weight.

Embodiment 2

[0058] Preparation of carboxymethyl starch grafted acrylamide copolymer: in parts by weight, add 1 part of carboxymethyl starch to 90 parts of deionized water, heat to 90°C, and continuously stir for gelatinization under nitrogen protection for 0.5h , cooling; then add the initiator potassium persulfate, the initiator concentration is 4.25 × 10 4 mol / L; then add 3 parts of monomeric acrylamide, at 45 degrees Celsius, the reaction time is 1 hour, after the reaction is completed, the product is washed with absolute ethanol, and the product is dried under reduced pressure to constant weight.

Embodiment 3

[0060] Preparation of carboxymethyl starch grafted acrylamide copolymer: in parts by weight, add 2.5 parts of carboxymethyl starch to 80 parts of deionized water, heat to 70°C, and keep stirring under nitrogen protection for 1.5 hours of gelatinization , cooling; then add the initiator potassium persulfate, the initiator concentration is 6.80×10 4mol / L; then add 5 parts of monomeric acrylamide, at 65 degrees Celsius, the reaction time is 6 hours, after the reaction, wash the product with absolute ethanol, and dry the product under reduced pressure to constant weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com