3D printer for plastic model and printing method thereof

A 3D printer and plastic model technology, applied in the field of 3D printing, can solve the problems of reduced storage capacity of collection boxes, increased labor load, and impact on health, and achieve the effects of reducing workload, improving production efficiency, and avoiding waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

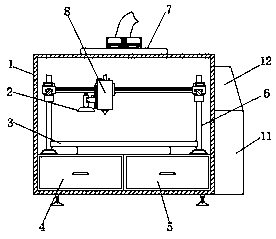

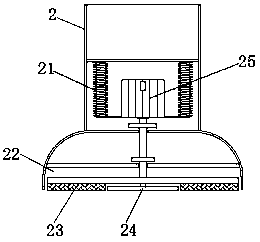

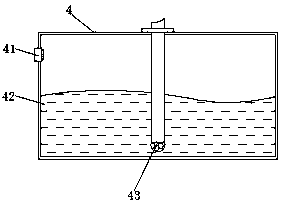

[0050] Input the data of the plastic model to be processed in the control box 12, the printing processing head 8 ejects the printing material, and through the operation of the moving processing assembly 6, the printing processing head 8 installed on the moving processing assembly 6 can be accurately transferred to the desired position, Print out the desired model on the processing table 3; collect the exhaust gas generated during printing through the collection and cleaning cover 7 on the upper end of the printing box 1, and then transport it to the air intake pipe 43 through the air pipe, and the lower end of the air intake pipe 43 is immersed in the dissolved adsorption liquid 42. The adsorption treatment of the adsorption liquid 42, the gas is discharged from the gas outlet 41; after the printing is completed, the waste is processed on the processing table 3, the cleaning assembly 2 slides down the slide rail of the printing processing head 8, and the motor 25 in the cleaning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com