A connection structure and method for a concrete frame and a light steel roof

A technology for connecting structures and concrete, applied in the direction of roofs, building components, building structures, etc., can solve the problems of fighting between new foundations and existing foundations, large space for foundation optimization, and difficulty in quality control, so as to reduce damage and reduce damage. Transformation, shortening construction period and quality control, and promoting the effect of great value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0030] It should be noted that the structures, proportions, sizes, etc. shown in the drawings attached to this specification are only used to match the content disclosed in the specification, for those who are familiar with this technology to understand and read, and are not used to limit the implementation of the present invention Any modification of the structure, change of the proportional relationship or adjustment of the size shall still fall within the scope of the technical content disclosed in the present invention without affecting the effect and purpose of the present invention. In the range.

[0031] At the same time, terms such as "upper", "lower", "left", "right", "middle" and "one" quoted in this specification are only for the convenience of description and are not used to limit this specification. The practicable scope of the invention and the change or adjustment of its relative relationship shall also be regarded as the practicable scope of the present inventi...

Embodiment 1

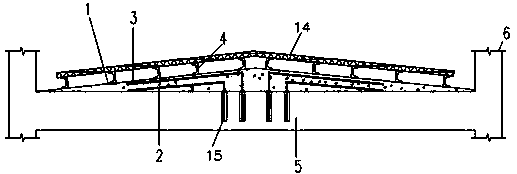

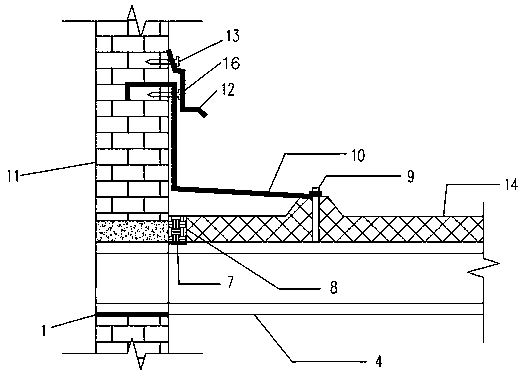

[0033] Such as Figure 1~2 As shown, the present invention discloses a connection structure between a concrete frame and a light steel roof, including a purlin supporting plate 1, a rear anchoring steel bar 2, a concrete slope layer 3, purlins 4, a concrete frame, a frame filling wall 11 and a light steel roof pressing Shaped steel plate 14, the concrete frame includes a concrete frame beam 5 and a concrete frame column 6, wherein there are two concrete frame columns 6, which are respectively arranged on both sides of the concrete frame beam 5 to support the concrete frame beam 5, and the rear anchoring steel bar 2 is A plurality of them, wherein a plurality of rear anchoring steel bars 2 are fixed on the concrete frame beam 5 to form a roof structure, wherein the concrete slope layer 3 is formed by pouring the roof structure of the rear anchoring steel bars 2, and the purlin supporting plate 1 is fixed on the concrete slope On the layer 3, the purlin 4 is fixed on the purlin ...

Embodiment 2

[0035] Such as Figure 1~2 As shown, the present invention discloses a connection structure between a concrete frame and a light steel roof, including a purlin supporting plate 1, a rear anchoring steel bar 2, a concrete slope layer 3, purlins 4, a concrete frame, a frame filling wall 11 and a light steel roof pressing Shaped steel plate 14, the concrete frame includes a concrete frame beam 5 and a concrete frame column 6, wherein there are two concrete frame columns 6, which are respectively arranged on both sides of the concrete frame beam 5 to support the concrete frame beam 5, and the rear anchoring steel bar 2 is A plurality of them, wherein a plurality of rear anchoring steel bars 2 are fixed on the concrete frame beam 5 to form a roof structure, wherein the concrete slope layer 3 is formed by pouring the roof structure of the rear anchoring steel bars 2, and the purlin supporting plate 1 is fixed on the concrete slope On the layer 3, the purlin 4 is fixed on the purlin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com