Grinding material forming mold with rapid heat dissipation function

A technology for molding molds and functions, which is applied in the direction of ceramic molding machines, mold auxiliary parts, manufacturing tools, etc., can solve the problems of slow heat dissipation, unfavorable grinding disc molding, and slow molding speed, so as to achieve fast heat dissipation and overall weight Lightening, the effect that the structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

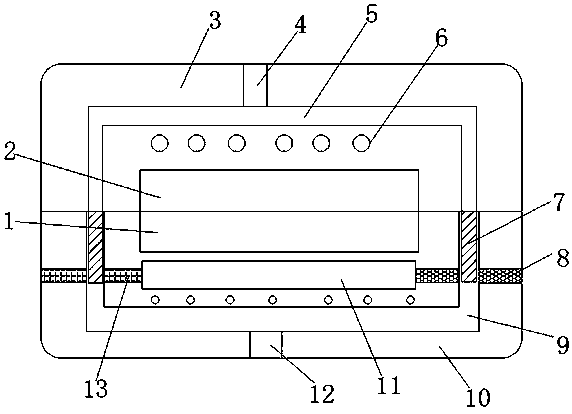

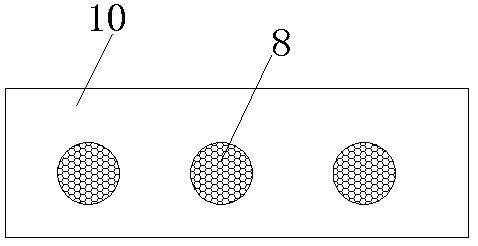

[0018] refer to Figure 1-2 , an abrasive forming mold with rapid heat dissipation function, comprising an upper template 3 and a lower template 10, the upper template 3 is provided with an upper flow groove 5 with an inverted concave structure, and the top outer wall of the upper template 3 is provided with a vertically arranged The water inlet 4, and the inside of the water inlet 4 communicates with the inside of the upper flow tank 5, the two ends of the upper flow groove 5 are respectively welded with vertical connection sleeves 7, and the outer wall of one side of the upper formwork 3 is provided with etc. The heat dissipating holes 6 distributed at a distance, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com