Method for controlling depth of blind slot of PCB buried copper block

A copper plate and blind slot technology, which is applied in the details of milling machine equipment, metal processing equipment, milling machine equipment, etc., can solve the problem of flatness at the bottom of the slot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

[0025] In a preferred embodiment, a method for controlling the depth of a blind groove of a PCB buried copper plate copper block of the present invention comprises the following steps:

[0026] a. Drill holes on PCB buried copper plate;

[0027] b. Grinding the front of the PCB buried copper plate;

[0028] c. Mill blind slots on PCB buried copper boards;

[0029] d. Sink the copper plate on the PCB buried copper plate;

[0030] Among them, the controlled depth milling of blind slots includes the following steps:

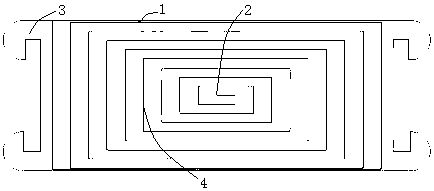

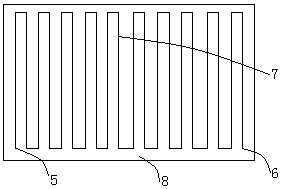

[0031] 1. Design the gong belt: the diameter of the milling cutter used is 2.4mm, the lower point of the milling cutter is set at the center of the blind groove, the cutting line of the milling cutter is in the shape of a zigzag, and the overlapping width of the cutting line is 0.96mm; figure 1 As shown, the reference numbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com