Ceramic particle multi-scale reinforced metal base composite wear-resistant raking tooth head and manufacturing method thereof

A metal matrix composite, ceramic particle technology, applied in metal processing equipment, rails, ballast layers, etc., can solve the problem that most of the tooth head structure cannot be fully applied, the thickness of the composite wear-resistant layer on the tooth head surface is limited, and the service life is limited, etc. problems, to achieve the effect of promoting the metallurgical composite process of inlaid casting, omitting the assembly process, and avoiding brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

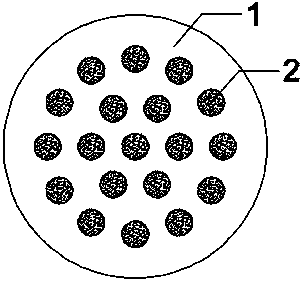

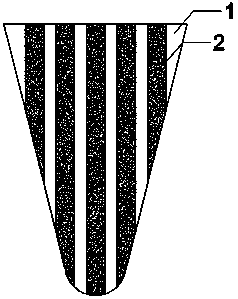

[0050] This example provides Al 2 o 3 - High-manganese steel ceramic particles multi-scale reinforced metal-based composite wear-resistant rake tooth head, the ceramic particle multi-scale reinforced metal-based composite wear-resistant rake tooth head is composed of figure 1 , 2 The metal matrix 1 is composed of a rod-shaped composite material 2, and a plurality of evenly distributed rod-shaped composite materials are wrapped in the metal matrix. The diameter of the rod-shaped composite material is 5mm, and the lengths of the three layers of rod-shaped composite materials from outside to inside are 15mm, 30mm, and 45mm, respectively. The tooth head of the rake tooth is conical.

[0051] The material of the metal matrix is high manganese steel.

[0052] Al described in this example 2 o 3 -The preparation method of high manganese steel ceramic particles multi-scale reinforced metal matrix composite wear-resistant rake tooth head is as follows:

[0053]In step (1), 40-6...

Embodiment 2

[0067] The ceramic particle multi-scale reinforced metal matrix composite wear-resistant rake tooth head provided in this embodiment is composed of figure 1 , 2 The metal matrix 1 is composed of a rod-shaped composite material 2, and a plurality of evenly distributed rod-shaped composite materials are wrapped in the metal matrix. The diameter of the rod-shaped composite material is 2 mm, and the lengths of the three layers of rod-shaped composite materials from outside to inside are 12 mm, 24 mm, and 36 mm, respectively. The tooth head of the rake tooth is conical.

[0068] The material of the metal substrate is high chromium cast iron.

[0069] The preparation method of the ceramic particle multi-scale reinforced metal matrix composite wear-resistant rake tooth head described in this embodiment is as follows:

[0070] In step (1), 80-120 mesh ceramic particles, alloy powder and plasticizer are mixed evenly and then filled into a hollow cylindrical mold, and pressed for 15 ...

Embodiment 3

[0084] This embodiment provides TiC-high manganese steel ceramic particle multi-scale reinforced metal-based composite wear-resistant rake tooth head, the ceramic particle multi-scale reinforced metal-based composite wear-resistant rake tooth head is composed of figure 1 , 2 The metal matrix 1 is composed of a rod-shaped composite material 2, and a plurality of evenly distributed rod-shaped composite materials are wrapped in the metal matrix. The diameter of the rod-shaped composite material is 5mm, and the lengths of the three layers of rod-shaped composite materials from outside to inside are 15mm, 30mm, and 45mm, respectively. The tooth head of the rake tooth is conical.

[0085] The material of the metal matrix is high manganese steel.

[0086] The preparation method of the TiC-high manganese steel ceramic particle multi-scale reinforced metal matrix composite wear-resistant rake tooth head described in this example is as follows:

[0087] In step (1), 40-60 mesh cera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com