Flywheel seat for centrifugal collision crusher and centrifugal collision crusher

A pulverizer and flywheel technology, applied in the field of flywheel seat, can solve problems such as flywheel looseness, and achieve the effect of eliminating potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

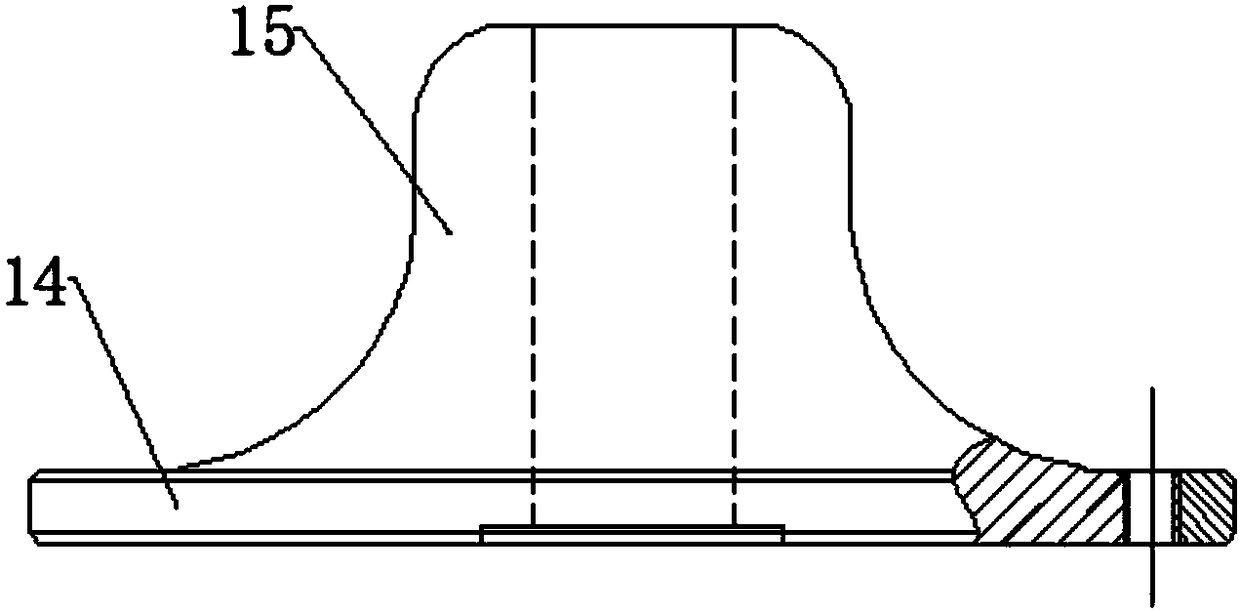

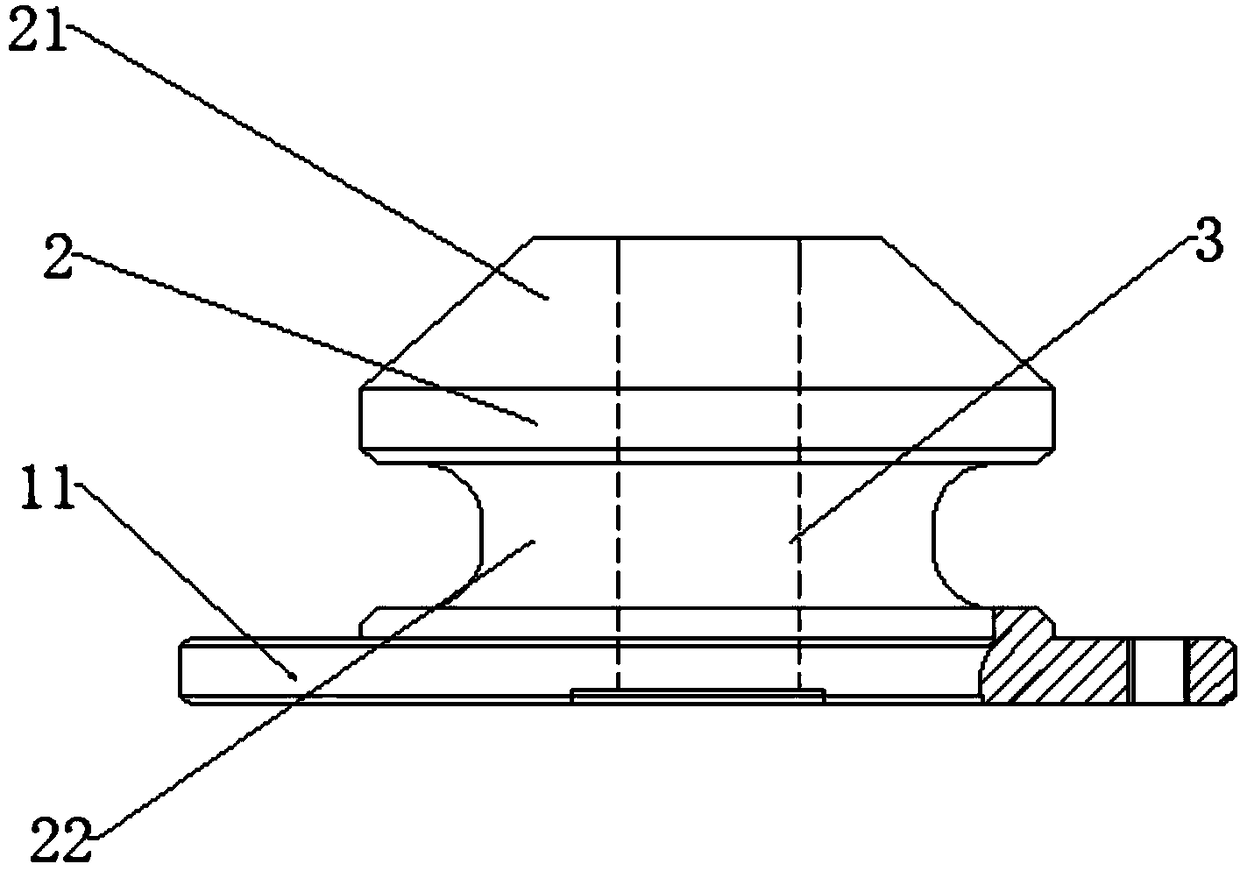

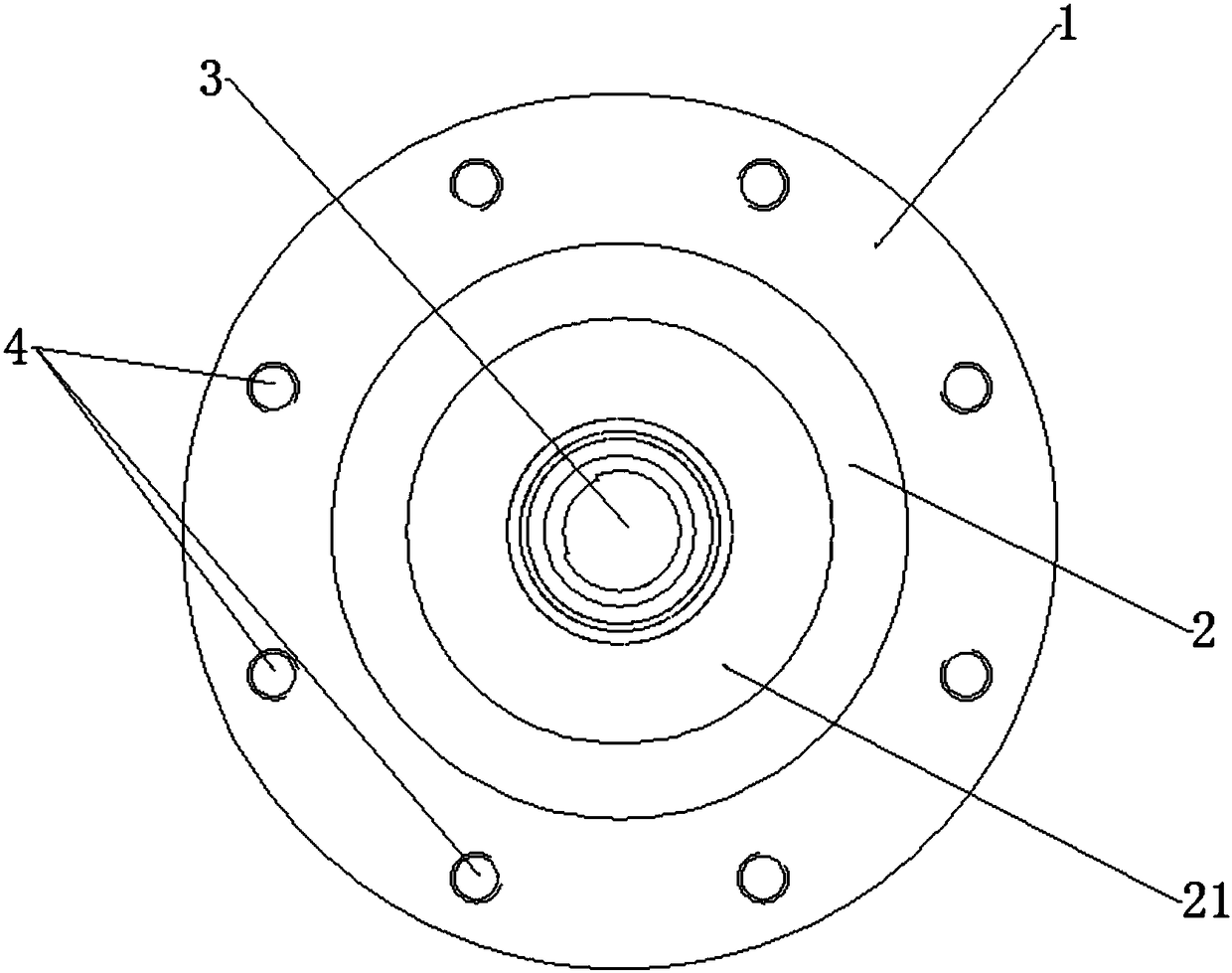

[0025] Please refer to Figures 2 to 6 , the flywheel seat provided by the present invention, the wheel seat includes a base 1 and a seat head 2 arranged concentrically from bottom to top, and the center of the bottom of the flywheel seat has a shaft hole 3 extending through the base 1 and extending into the seat head 2; the base 1 is disc-shaped, and the base 1 has a plurality of second connection points 95 arranged around its center; it should be understood that the second connection points 95 cooperate with the first connection points 4 of the above-mentioned flywheel, which The positions correspond to each other; the seat head 2 has a truncated seat crown; the diameter of the base 1 is larger than the diameter of the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com