Pressure rising type fuel expulsion system

A fuel injection system, pressure technology, applied in the direction of fuel injection control, fuel injection device, charging system, etc., can solve problems such as damage to the engine or vehicle, trouble, failure of fuel pressure control parts, control units or other parts, etc. Achieve the effect of protecting vibration and preventing insufficient purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

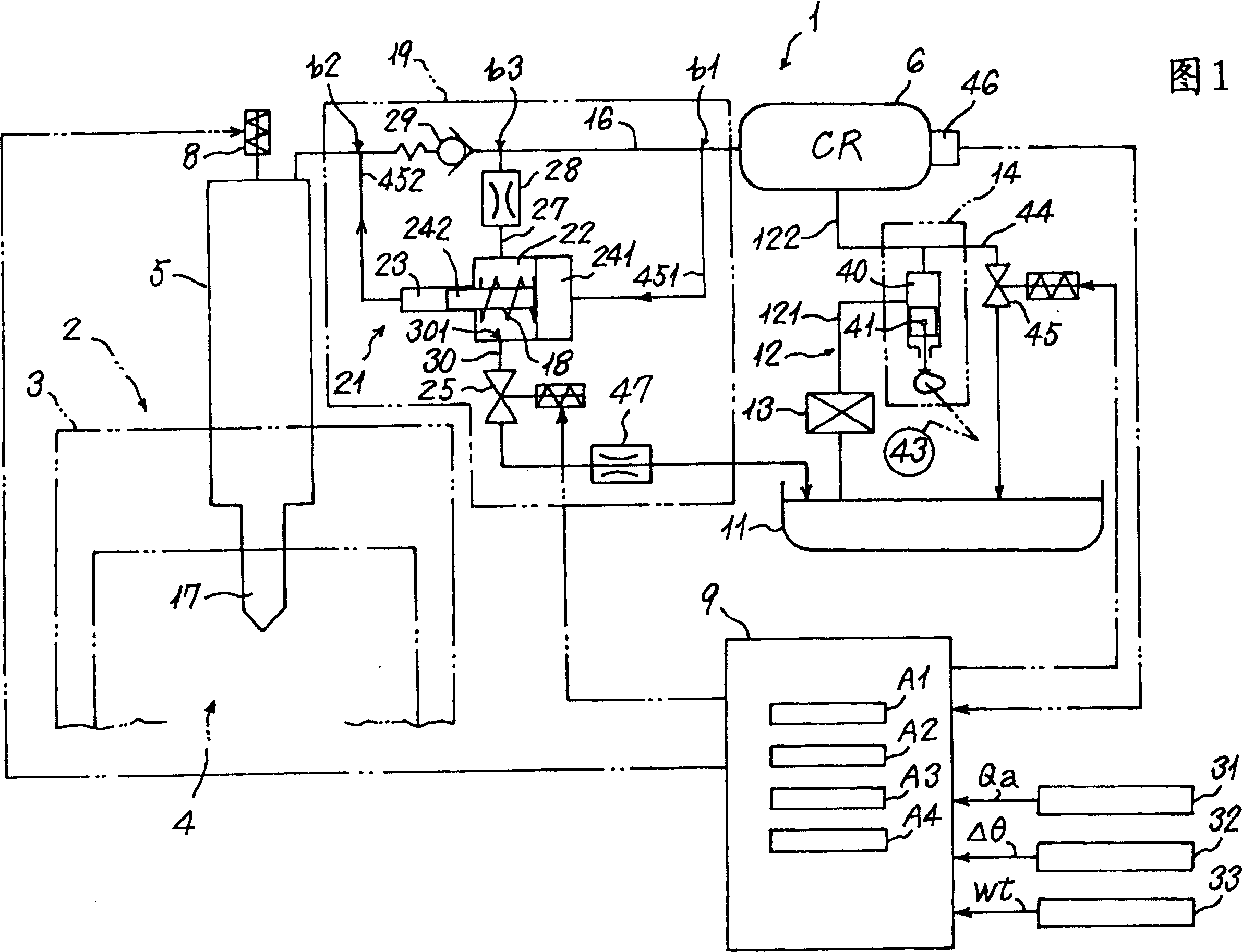

[0024] The present invention will be described with reference to an embodiment shown in FIGS. 1 to 3.

[0025] A pressure-increasing fuel injection system 1 is installed in an unshown multi-cylinder diesel engine 2 (called "engine 2"). Specifically, the pressure-increasing fuel injection system 1 (called "fuel injection system 1") is installed on the engine block 3 of the engine 2 and pressurized in the two-step injection mode M1 or the single-step injection mode M2 described later Fuel is injected into the combustion chamber 4 in the engine block 3.

[0026] The fuel injection system 1 includes: an injector 5 to inject fuel into each combustion chamber 4 in the engine body 3; a common fuel pipe 6 to supply high-pressure fuel to the injector 5; a high-pressure fuel source 7 to High-pressure fuel is supplied to the common supply pipe 6; and an engine controller 9 that controls the operation of the injector solenoid valve 8 of the injector 5.

[0027] The high-pressure fuel source...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com