An S-type mild steel energy dissipation damper for steel-concrete composite shear wall

A combined shear wall and concrete technology, applied in building types, building components, earthquake resistance, etc., can solve the problems of difficulty in post-earthquake repair work, affecting people's normal production and life, and damage to the bottom area of shear walls, and improving ductility. and energy consumption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in further detail below in conjunction with accompanying drawing:

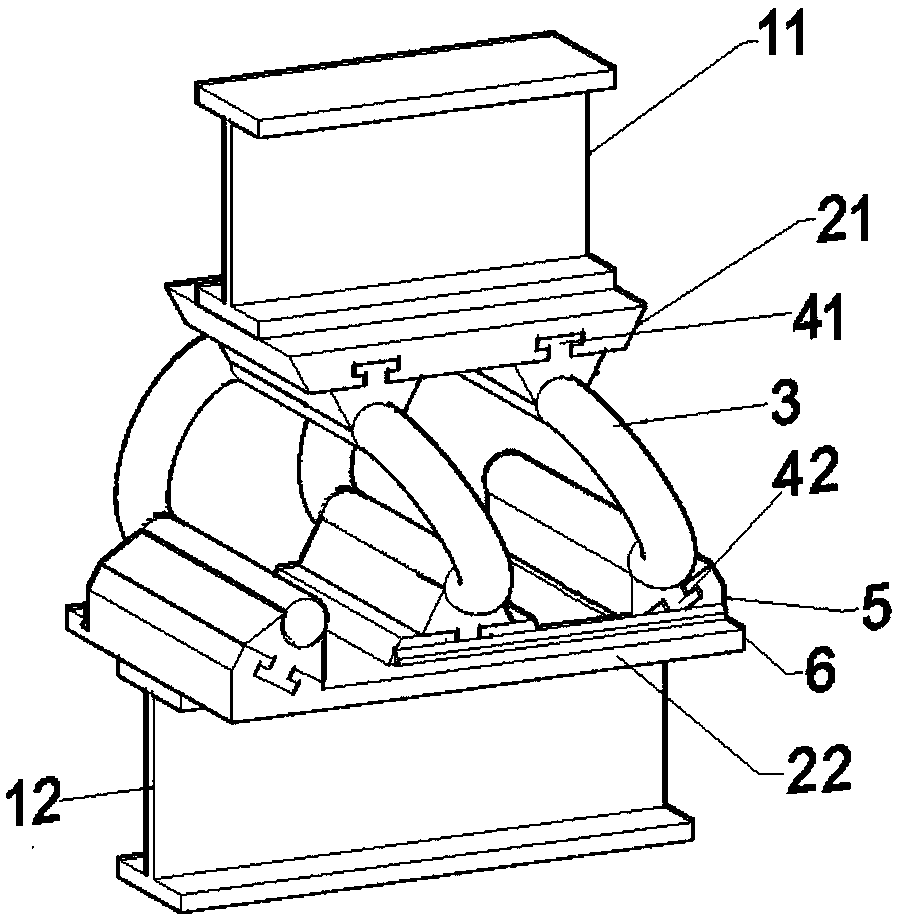

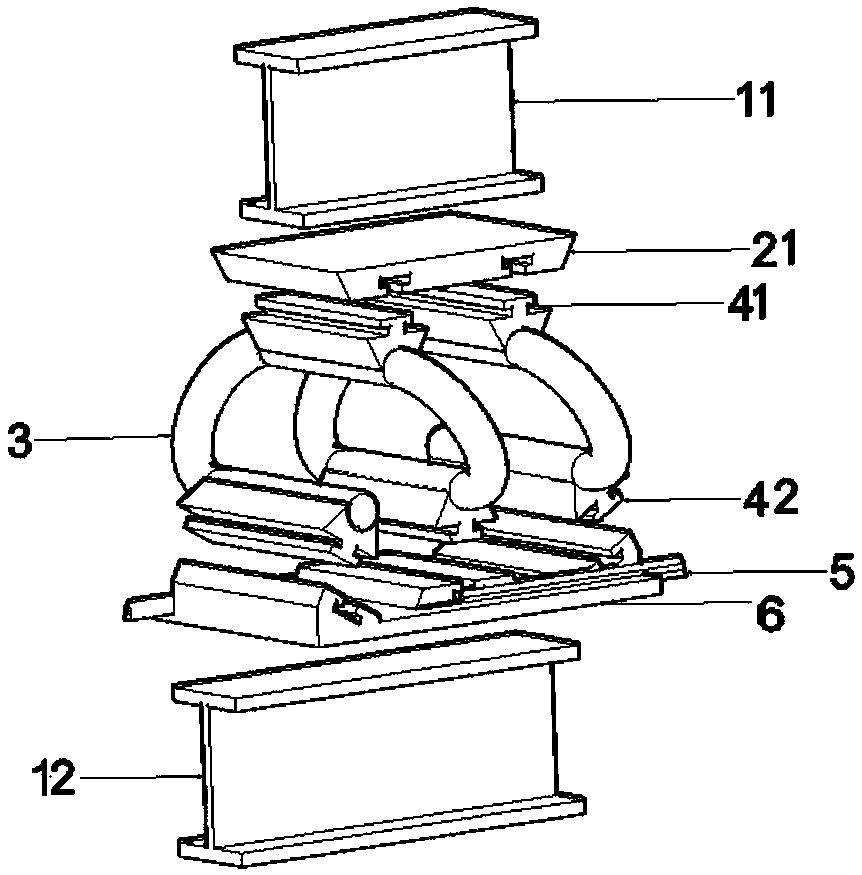

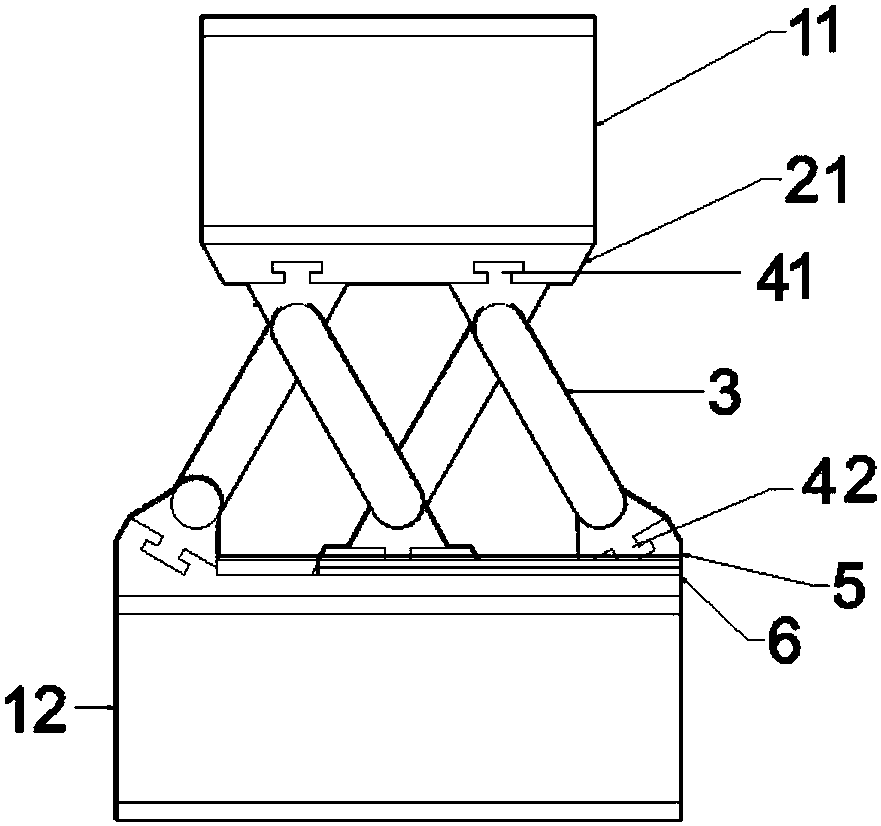

[0024] refer to figure 1 , the S-type mild steel energy dissipation damper for steel-concrete composite shear walls according to the present invention comprises the first I-beam 11, the first connecting plate 21, the mild steel rod 3, the first I-beam distributed sequentially from top to bottom Two connecting plates 22 and the second I-beam 12; the upper surface of the first connecting plate 21 is connected with the flange of the first I-beam 11 bottom, and the lower surface of the second connecting plate 22 is connected with the second I-beam 12 top The flanges of the steel bar 3 are connected to each other, the upper part of the mild steel rod 3 is engaged with the lower surface of the first connecting plate 21, and the lower part of the mild steel rod 3 is engaged with the upper surface of the second connecting plate 22.

[0025] The top of the mild steel rod 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com