Urea formaldehyde photochromic microcapsule and preparation method thereof

A photochromic and microcapsule technology, applied in the chemical industry, can solve the problems of loss of reversible discoloration performance, prone to oxidative fission, weakening of discoloration and color depth, etc., to improve reversible discoloration performance and fatigue resistance, including The covering method is simple and efficient, and the effect of long half-life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

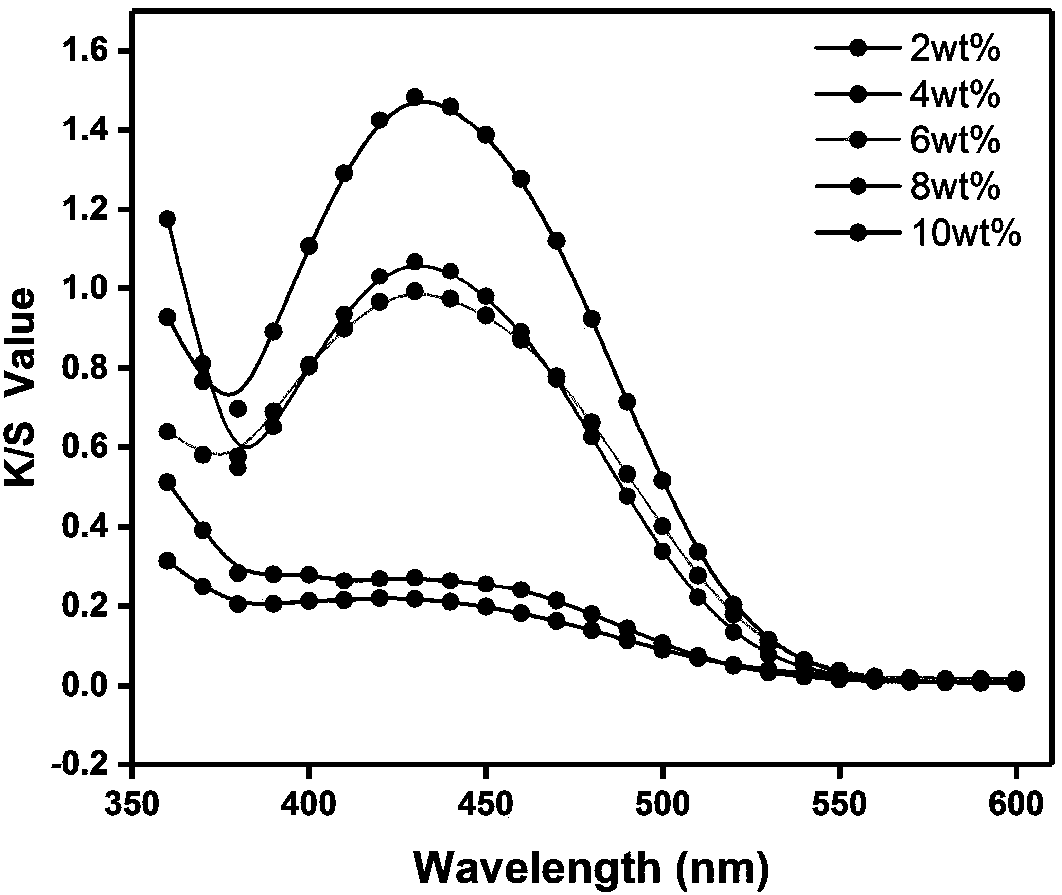

Image

Examples

Embodiment 1

[0026] (1) Preparation of prepolymer, weigh 2g urea, dissolve in 8ml deionized water, transfer to a three-necked flask, add weighed 18.5g formaldehyde solution (containing 1.85g formaldehyde) while stirring, then add triethanolamine Adjust the pH to 8.5, slowly raise the temperature to 75°C, and react with magnetic stirring for 1h, cool to room temperature, and magnetically stir for 1h to obtain a urea-formaldehyde prepolymer;

[0027] (2) Add 0.9625g of spiropyran photochromic compound and 20ml of dioctyl phthalate into a round bottom flask, heat to 80°C and stir until completely dissolved, after cooling, add 100ml of 2% dodecyl Sodium alkylbenzene sulfonate was used as emulsifier, sonicated for 25 minutes, then 4.5 g of acrylic acid monomer was added to continue ultrasonic dispersion for 10 minutes to increase the stability of the system, and then magnetically stirred for 2 hours to prepare an O / W emulsified system;

[0028] (3) Slowly add the prepolymer prepared in step (1)...

Embodiment 2

[0030] (1) Preparation of prepolymer, weigh 1.9g urea, dissolve in 8ml deionized water, transfer to a three-necked flask, add weighed 18.5g formaldehyde solution (containing 1.85g formaldehyde) while stirring, and then add three Adjust the pH to 8.5 with ethanolamine, slowly raise the temperature to 75°C, react with magnetic stirring for 1 hour, cool to room temperature, and stir magnetically for 1 hour to obtain a urea-formaldehyde prepolymer;

[0031] (2) Add 0.8g of spirooxazine photochromic compound and 20ml of dioctyl phthalate into a round bottom flask, heat to 80°C and stir until completely dissolved, after cooling, add 100ml of styrene with a mass fraction of 2% Maleic anhydride was used as an emulsifier, sonicated for 25 minutes, then 4.5 g of acrylic acid monomer was added to continue ultrasonic dispersion for 10 minutes to increase the stability of the system, and then magnetically stirred for 2 hours to prepare an O / W emulsified system;

[0032] (3) Slowly add the ...

Embodiment 3

[0034] (1) Preparation of prepolymer, weigh 2.1g urea, dissolve in 10ml deionized water, transfer to a three-necked flask, add weighed 18.5g formaldehyde solution (containing 1.85g formaldehyde) while stirring, then add three Adjust the pH to 8.5 with ethanolamine, slowly raise the temperature to 75°C, react with magnetic stirring for 1 hour, cool to room temperature, and stir magnetically for 1 hour to obtain a urea-formaldehyde prepolymer;

[0035] (2) Add 1g of benzopyran photochromic compound and 20ml of dioctyl phthalate into a round bottom flask, heat to 80°C and stir until completely dissolved. After cooling, add 100ml of Span80 with a mass fraction of 2%. Emulsifier, ultrasonic for 25 minutes, then add 4.5g of acrylic acid monomer and continue ultrasonic dispersion for 10 minutes to increase the stability of the system, and then magnetically stir for 2 hours to prepare an O / W emulsification system;

[0036] (3) Slowly add the prepolymer prepared in step (1) dropwise in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com