Waste oil recycling method of capacitor aluminum shell punching oil

A technology for stamping oil and capacitors, which is applied in chemical instruments and methods, semi-permeable membrane separation, and sediment separation by centrifugal force. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

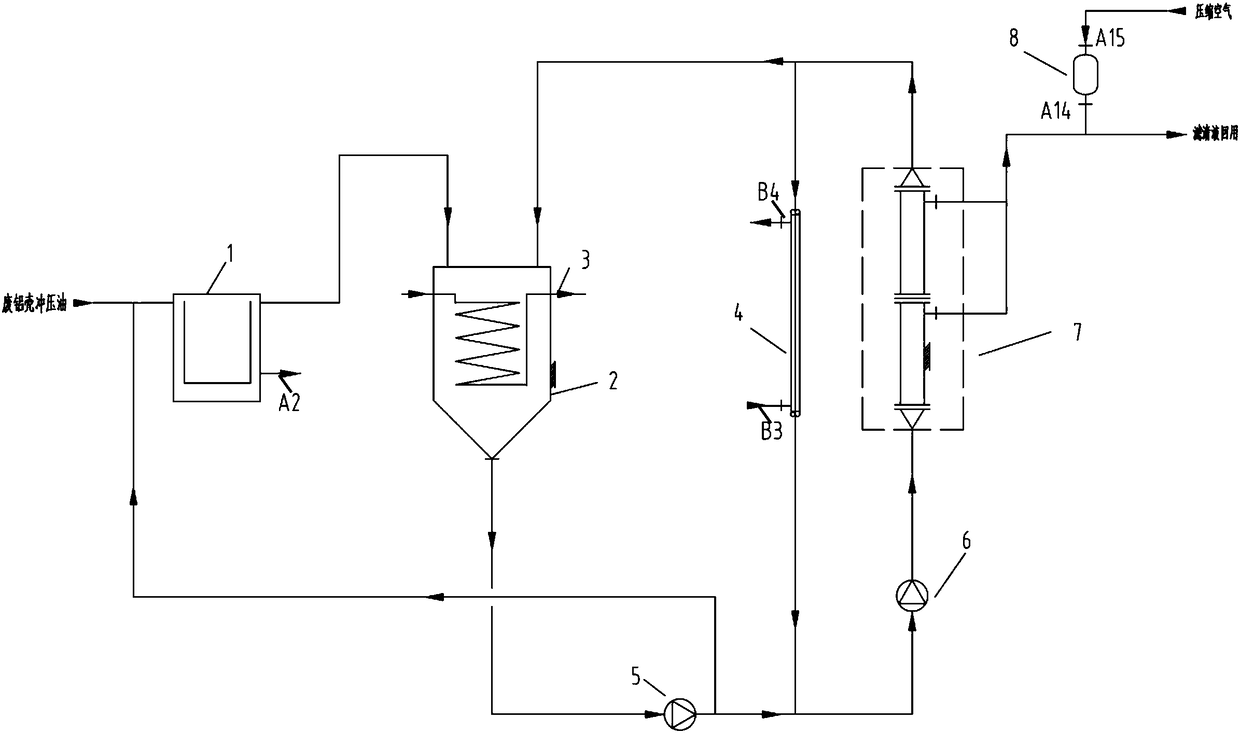

[0036] like figure 1 As shown in the figure, a waste oil recovery device for aluminum casing stamping oil of capacitors includes: a high-speed centrifuge 1, a raw material tank 2, a heating coil 3, a temperature control jacket 4, a feeding pump 5, a circulating pump 6, a Flow circulation group 7 and isolation backflush tank 8.

[0037]The high-speed centrifuge, the raw material tank, the feeding pump, the circulation pump, and the cross-flow circulation group are connected in sequence, and the two ends of the temperature control jacket are respectively connected with the two ends of the cross-flow circulation group to form a circulation loop; the cross-flow circulation The concentrated oil in the group passes through the raw material tank and the feed pump in turn and returns to the high-speed centrifuge; the heating coil is set on the raw material tank, and the isolation backflush tank is set on the filtered oil outlet of the cross-flow circulation group .

[0038] Wherein,...

Embodiment 2

[0047] like figure 1 As shown in the figure, a waste oil recovery device for aluminum casing stamping oil of capacitors includes: a high-speed centrifuge 1, a raw material tank 2, a heating coil 3, a temperature control jacket 4, a feeding pump 5, a circulating pump 6, a Flow circulation group 7 and isolation backflush tank 8.

[0048] The high-speed centrifuge, the raw material tank, the feeding pump, the circulation pump, and the cross-flow circulation group are connected in sequence, and the two ends of the temperature control jacket are respectively connected with the two ends of the cross-flow circulation group to form a circulation loop; the cross-flow circulation The concentrated oil in the group passes through the raw material tank and the feed pump in turn and returns to the high-speed centrifuge; the heating coil is set on the raw material tank, and the isolation backflush tank is set on the filtered oil outlet of the cross-flow circulation group .

[0049] Wherein...

Embodiment 3

[0058] like figure 1 As shown in the figure, a waste oil recovery device for aluminum casing stamping oil of capacitors includes: a high-speed centrifuge 1, a raw material tank 2, a heating coil 3, a temperature control jacket 4, a feeding pump 5, a circulating pump 6, a Flow circulation group 7 and isolation backflush tank 8.

[0059] The high-speed centrifuge, the raw material tank, the feeding pump, the circulation pump, and the cross-flow circulation group are connected in sequence, and the two ends of the temperature control jacket are respectively connected with the two ends of the cross-flow circulation group to form a circulation loop; the cross-flow circulation The concentrated oil in the group passes through the raw material tank and the feed pump in turn and returns to the high-speed centrifuge; the heating coil is set on the raw material tank, and the isolation backflush tank is set on the filtered oil outlet of the cross-flow circulation group .

[0060] Wherein...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com