A fiber-reinforced gypsum composite material with ultra-high ductility and its preparation method

A technology of composite materials and fiber gypsum, applied in the field of building materials, can solve the problems of low ductility and toughness, achieve the effect of improving the low toughness of gypsum, low economic cost, and expanding the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

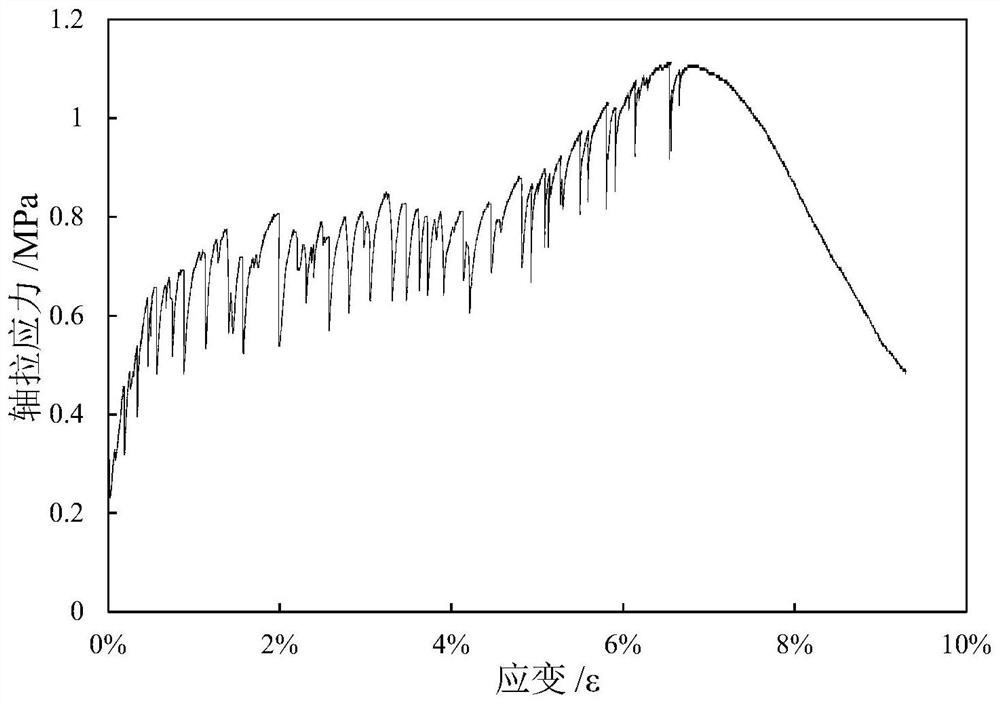

Embodiment 1

[0035] Contain 3 products in this example, and its serial number is recorded as 1-1, 1-2, 1-3 respectively.

[0036] In this embodiment, the fiber-reinforced gypsum composite material with ultra-high ductility includes β-type gypsum powder, retarder, thickener, tap water and polyethylene fiber. Each component is shown in Table 1 below, and each part in the table is the content in parts by weight. In Table 1, the polyethylene fiber has a length of 18 mm and an aspect ratio of 700.

[0037] Table 1 product components and parts by weight content

[0038] label β type gypsum powder retarder thickener water polyethylene fiber 1-1 1635 1.5 4 600 15 1-2 1635 1.5 4 600 20 1-3 1635 1.5 4 600 25

[0039] The preparation process of the fiber reinforced gypsum composite material in this example is as follows:

[0040] (1) Add 1635 parts of gypsum powder and 1.5 parts of retarder into the mixer, stir the dry powder for 2-3 minutes, and m...

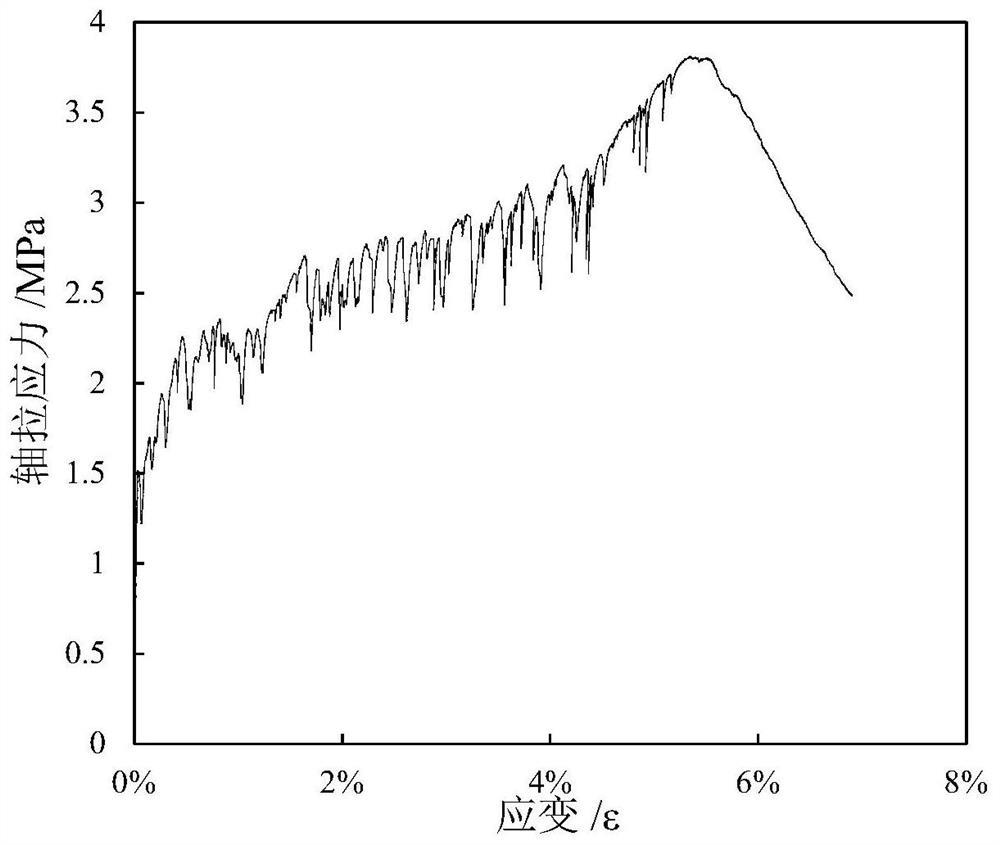

Embodiment 2

[0049] Contain 3 products in this example, and its serial number is recorded as 2-1, 2-2, 2-3 respectively.

[0050] In this example, the fiber-reinforced gypsum composite material with ultra-high ductility includes α-type gypsum powder, retarder, thickener, tap water and polyethylene fiber. The components are shown in Table 3 below, and each part in the table is by weight Part content, wherein, the polyethylene fiber length in Table 3 is 18mm, aspect ratio is 700.

[0051] Table 3 product components and parts by weight

[0052] label α type gypsum powder retarder thickener water polyethylene fiber 2-1 1720 1.5 4 600 15 2-2 1720 1.5 4 600 20 2-3 1720 1.5 4 600 25

[0053] The preparation process of the fiber-reinforced gypsum composite material with ultra-high ductility in this embodiment is as follows:

[0054] (1) Add 1720 parts of gypsum powder and 1.5 parts of retarder to the mixer, stir the dry powder for 2-3 minutes, a...

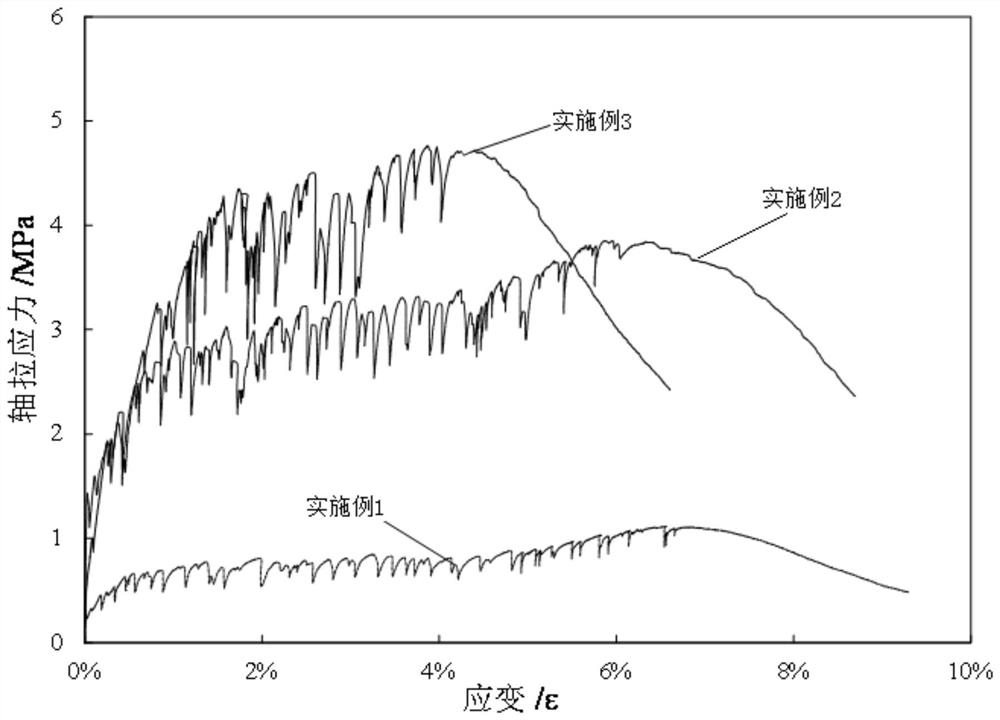

Embodiment 3

[0063] Contain three products in this example, and its serial number is recorded as 3-1, 3-2, 3-3 respectively.

[0064] In this embodiment, the fiber-reinforced gypsum composite material with ultra-high ductility includes α-type gypsum powder, cement, fly ash, retarder, thickener, tap water and polyethylene fiber. Each component is shown in Table 5 below, and each part in the table is the content in parts by weight. The polyethylene fiber in Table 5 has a length of 18 mm and an aspect ratio of 700.

[0065] Table 5 Product components and parts by weight

[0066] label α type gypsum powder cement fly ash retarder thickener water polyethylene fiber 3-1 1205 85 430 1.5 4 600 15 3-2 1205 85 430 1.5 4 600 20 3-3 1205 85 430 1.5 4 600 25

[0067] The preparation process of the fiber-reinforced gypsum composite material with ultra-high ductility in this embodiment is as follows:

[0068] (1) Add 1205 parts of gypsum powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com